Unlocking the "New Horizon" of Edge AI: How Event-based Vision Empowers Industrial Manufacturing to Release New Productivity?

![]() 07/18 2024

07/18 2024

![]() 649

649

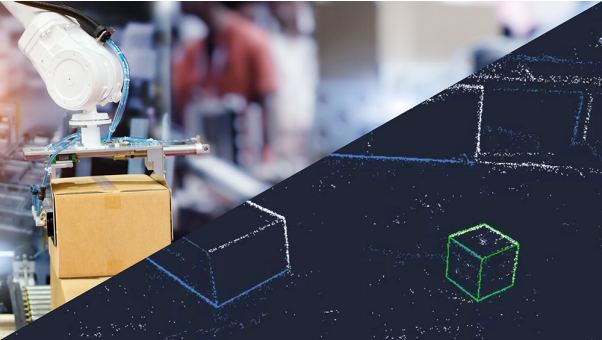

In smart factories, AGV/ARM robots utilize 3D vision perception to accurately identify and pick items from shelves. They can also collaborate with human colleagues to safely transport goods to production lines. On the production line, machines equipped with smart cameras, akin to having intelligent eyes, can read labels and interpret markings. Through machine deep learning, machine vision systems comprehend object shapes, calculate volumes, and perfectly pack them in the most space-efficient manner.

This might sound like a scene from science fiction, but in today's smart factories, artificial intelligence is reshaping industrial production and smart manufacturing, from quality control to predictive maintenance, from collaborative robots to digital twins... Machine vision systems integrated with AI technology collect data through cameras and sensors, enabling industrial equipment to "see" and analyze manufacturing processes, control production quality, and ensure worker safety. They are the key technology leading the transition from industrial manufacturing to Industry 4.0.

With the further development and maturity of edge computing and large AI models, industrial manufacturing is ushering in a new round of transformation and reform, while also placing higher demands on machine vision systems. Traditional machine vision systems that perform single repetitive tasks can no longer meet the needs of future industrial production and smart manufacturing. We require machine vision systems that are more intelligent and capable of making independent decisions.

Event-based Vision Technology Unlocks a "New Horizon" for Industrial Manufacturing

In the field of industrial manufacturing, traditional machine vision systems capture continuous image data streams using frame-based cameras, which are then processed and analyzed by AI algorithms. However, this traditional approach has limitations, struggling to cope with the rapidly growing computational requirements of machines and the bandwidth demands for processing large amounts of data.

Unlike traditional frame-based image sensing technology, event-based vision sensing technology is inspired by the human visual system. It mimics the working mode of human vision, focusing only on changes or "events" occurring in the visual scene. This unique approach not only significantly reduces the amount of data and computational load required by machine vision systems but also optimizes data transmission and processing processes, achieving unprecedented efficiency.

Furthermore, the combination of AI algorithms and event-based vision sensing technology brings new autonomy and adaptability to industrial automation. By leveraging deep learning technology, machines can learn from vast amounts of data, continuously improving their decision-making capabilities. This symbiotic relationship between event-based vision sensing and AI enables machines to make intelligent, real-time adjustments, optimize processes, and minimize downtime.

Collaborating to Accelerate the Development of Advanced Edge Machine Vision Applications

To accelerate the deep integration and application of event-based vision technology in edge machine vision and industrial fields, Prophesee recently announced its collaboration with AMD to launch the industry's first event-based vision development kit compatible with the AMD Kria platform. This kit aims to create an efficient bridge for machine vision system designers and developers, enabling them to quickly evaluate and deploy cutting-edge industrial-grade solutions for smart cities, machine vision, security surveillance, retail analytics, and other fields, seamlessly connecting R&D and production processes.

Image: Prophesee Metavision Starter Kit – AMD Kria KV260 and Active Marker LED Board

AMD Kria SOM is suitable for edge AI applications, featuring abundant I/O interfaces, high energy efficiency, and cost-effectiveness, accelerating visual and robotic task processing. Combined with Prophesee's groundbreaking event-based vision technology, machine vision system developers can leverage the low-latency and low-power advantages of the Metavision platform to create applications that traditional frame-based vision solutions cannot achieve, making them more efficient. Prophesee also provides a comprehensive event-based vision software suite, optimization tools, event-based vision datasets, and open-source platform support, empowering developers in all aspects.

"Event-based vision sensing solutions are ideal for embedded vision applications," said Gareth Powell, Product Marketing Director at Prophesee. "A typical use case we can realize based on the Kria platform is precise placement of port containers. By placing active markers on containers, our event-based vision system can achieve precise positioning and tracking of suspended containers in 3D space, ensuring the safety and accuracy of every operation."

Image: Examples of Prophesee's Event-based Vision Sensing Technology in Industrial Automation Applications

"Another typical application scenario is counting and classifying high-speed moving objects, such as grains or pills. Using Prophesee's event sensors can achieve detection accuracy of up to 99%," Powell added.

Currently, some developers and companies are developing innovative machine vision applications on the Prophesee and AMD Kria vision kit, such as LogicTronix, a company specializing in developing machine learning software, which has successfully developed an application for detecting and tracking vehicles and personnel. This application will soon be available on the Kria App Store.

Powell said, "In the field of industrial automation, Prophesee's event-based vision technology, with its fast response, low computational demand, and energy-efficient characteristics, provides unique advantages for the deep integration of embedded vision and AI functions."

Event-based vision technology enables machines to quickly identify and respond to critical events in the environment, thereby enhancing productivity. Whether detecting abnormalities on production lines, identifying quality defects in real-time, or monitoring worker safety, event-based vision sensing technology provides smart factories with unparalleled efficiency and accuracy. In various industries such as automotive manufacturing, electronic component production, food processing, and pharmaceutical manufacturing, event-based vision sensing technology demonstrates broad application prospects, injecting continuous innovation vitality and robust momentum into the new productivity of the Industry 4.0 era.