The particle counter module accurately monitors particulate pollution to reduce the harm of static electricity and particulate pollution to the microelectronics industry

![]() 06/11 2024

06/11 2024

![]() 552

552

Static electricity poses great harm to the microelectronics industry. Static charges cause the damage of electrostatic discharge (and related electromagnetic wave interference) and the particulate pollution caused by electrostatic adsorption, which are very strict for the protection of static electricity in electronic factories for the electronic industry manufacturing process.

Static electricity is generated because the electron energy levels of each material are different, and charge transfer occurs when two different materials come into contact. Due to the negative effects of static electricity, it makes it more difficult to maintain high-level product quality and yield. With the acceleration of the miniaturization and refinement process of devices, the pattern feature size and surface deposition layer thickness of high-density integrated circuits have both been reduced to the micrometer level, making them more vulnerable to the impact of particles. Particle deposition on the surface of the substrate can easily cause substrate point defects or even poor line defect characteristics, reducing the yield.

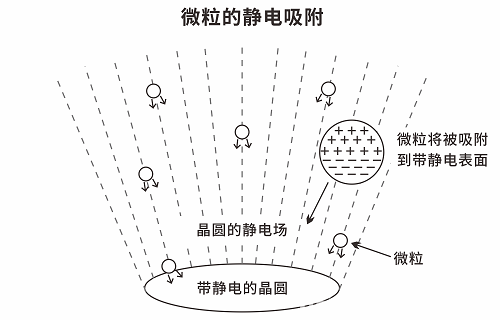

Particulate pollution is relatively an environmental issue. Particles falling off may be due to electrostatic adsorption, gravity, or random drift. To make electrostatic adsorption the main cause, attracting and adhering particles to the surface, the size of the particles is related to the electrostatic charge on the surface. The following figure compares: at a distance, gravity, random drift diffusion, and the electrostatic field formed by electrostatic charges, taking a strength of 200 V/cm as an example, the sedimentation speed of particles of different sizes.

While controlling static electricity damage, attention should also be paid to monitoring particles to ensure the cleanliness of the production environment. By monitoring the change parameters of particles in real-time, if the particle concentration exceeds the standard, timely detection can be made, and targeted measures can be taken for prevention and improvement to reduce the dust particles falling on the surface of chips and equipment, reduce product damage caused by particles themselves and electrostatic particle adsorption (ESA), and improve the yield. A particle counter module OPC dust module-9301P-OEM from Industrial Sampling Networks has a detection range of up to 30 particle counting channels, covering particle sizes from 0.3um to 25um, with a flow rate of 0.1CFM (2.83LPM).

The component is installed on an easy-to-integrate board, including a particle sensor, a particle counting board, an integrated vacuum pump, a flow manifold with pre- and post-filters, a real-time clock/calendar with a backup battery, data recording and storage up to 65,000 sample records, 3.3V UART communication, and an operating voltage range of 7~15VDC. The Particles Plus 9301P-OEM exceeds ISO 21501-4 and JIS B9921 standards, ensuring compliance with on-board pulse height analyzers.