Anti-subsidy case nearing its end, revealing deeper difficulties of the EU

![]() 11/04 2024

11/04 2024

![]() 615

615

Regardless of the final outcome of the anti-subsidy case, one topic seems worth pondering: Will tariffs or price barriers definitely boost the competitiveness of the European automotive industry?

How important is the automotive industry and its supply chain in the EU system?

In the monthly newsletters of the European Automobile Manufacturers' Association (ACEA), the fundamentals of the EU automotive industry are often mentioned in passing: It involves 12.9 million jobs, accounting for 8.3% of all manufacturing employment in the EU, contributing over €390 billion in tax revenue to EU governments, contributing over 7% to the EU GDP, and performing well in terms of trade surplus and R&D expenditures.

As a footnote in the email, although the information is not the latest, its main purpose is to emphasize the importance of the automotive industry in the EU. However, based on this reference, for the current EU automotive market, especially against the backdrop of the continuous shrinking market size in various regions, the arrival of any strong competitors from outside the region will trigger high sensitivity among all local participants in Europe.

On October 4, after a year-long investigation, the European Commission held a vote on the draft final ruling on imposing anti-subsidy duties on Chinese electric vehicles: Among the 27 member states, 10 voted in favor, 5 voted against, and 12 abstained. Since there were fewer than 15 dissenting votes and they did not meet the requirement of representing 65% of the EU population, the EU's decision to impose unilateral tariffs on Chinese electric vehicles was approved. Despite immediate opposition from China's Ministry of Commerce, the European Union Chamber of Commerce in China, and the China Association of Automobile Manufacturers, which deemed the EU's move a direct violation of WTO rules and an unfair, non-compliant, and unreasonable protectionist practice. German automotive giants such as Volkswagen and Mercedes-Benz also explicitly opposed it, believing that protectionism cannot drive progress in the European automotive industry.

However, before the final ruling measures take effect on November 30, dialogue and negotiation between China and the EU regarding this case are still ongoing. According to the Ministry of Commerce's news on October 28, China and the EU have clarified that they will continue to use price undertakings as the solution to this case and have initiated the next phase of consultations. China hopes that both sides will accelerate their efforts to achieve a substantive breakthrough as soon as possible.

So, when detaching from the focus of negotiations and games, and returning our gaze to the EU market, some ripples caused by tariff "friction" gradually reveal multiple impacts, providing a glimpse into some deeper difficulties in the development of the EU automotive industry.

Most abstentions inherently indicate disagreement

In this vote, the majority were abstentions, not a majority in favor. Although abstentions are considered as votes in favor in the EU's deliberative procedures, Spain's shift from an initial position of support also indicates significant disagreements within the EU over strategic technological interests in electric vehicles.

The five dissenting votes came from Germany, Hungary, Slovakia, Slovenia, and Malta.

Germany's decision to vote against reflected pressure from the country's major automotive worker unions and industry leaders. In the context of shrinking overall demand for automobiles (including electric vehicles) in Europe and high production costs in Germany, increasing tariffs could harm competitiveness. After all, sales of Volkswagen, Mercedes-Benz, and BMW in the Chinese market account for about one-third of their global sales. During the voting process, although the reaction within Germany's three-party coalition government was complex, on the whole, the German authorities were more concerned that imposing tariffs might trigger a larger trade war, while countries like France and Italy called for a more resolute protection of local automotive industry interests.

Hungarian Prime Minister Orban warned that the current EU economic strategy represents an "economic cold war" and expressed a desire to maintain trade relations with both sides. He pointed out that the EU's imposition of tariffs on Chinese electric vehicles would be counterproductive, and that failing to consider the interests of the automotive industry when setting environmental goals and lacking planning would lead to more unemployment.

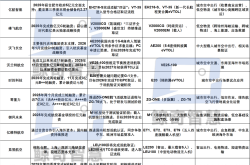

Slovakia, a member of the Visegrád Group (a regional integration organization in Central Europe) along with Hungary, exported the second-most large-displacement fuel vehicles to China in 2024 after Germany. Therefore, potential Chinese countermeasures to raise import tariffs on large-displacement fuel vehicles would have a significant impact on Slovakia. Currently, Slovakia's manufacturing industry is highly dependent on SUV exports, with automotive vehicles and parts accounting for about 78% of its exports to China in 2022 alone. A quarter of the revenue of Slovakia's largest automaker, Volkswagen Slovakia, comes from China. The Slovak Electric Vehicle Association (SEVA) stated that whether China adopts retaliatory tariffs or any countermeasures specifically targeting internal combustion engine SUVs, it will pose a threat to employment for relevant Slovak enterprises, factories, and even subcontracting industrial chains.

Slovenian Economy Minister Matja Han recently stated at the "Supplier Day" event in the Slovenian automotive industry that voting against imposing additional tariffs on Chinese electric vehicles was to protect the country's interests. He emphasized that this decision was made after consultations with industry stakeholders.

Why is the "pie" getting smaller?

Oliver Blume and Carlos Tavares, the CEOs of Volkswagen and Stellantis, the two largest multinational automotive companies in Europe, have recently been deeply involved in performance turmoil within their respective groups. The former is negotiating with Volkswagen's management and the IG Metall trade union regarding layoff plans for operations in Germany, while the latter is set to select a successor and start his retirement plan early due to the poor performance of their North American operations.

However, both have a keen and accurate understanding of the current state of the EU market. Blume wrote that European consumers are buying fewer cars and new competitors are entering the market, "The pie is getting smaller, but there are more guests at the table." The financially savvy Tavares stated that the sluggish market will exacerbate overcapacity in the European manufacturing system, "More factories are on the brink of forced closure."

According to data released by ACEA on October 22, new car registrations in the EU fell by 6.1% year-on-year in September 2024, marking the first consecutive two-month decline since July 2022. All three major regional markets in Europe showed negative growth: new car registrations in France fell by 11.1% year-on-year, Italy by 10.7%, and Germany by 7%. Only Spain achieved a year-on-year increase of 6.3% among larger regions.

Among European companies, Stellantis's "base" also suffered a significant setback: In September, its sales across Europe fell by about 26%. According to data released by JATO Dynamics, sales of the group's Fiat and Citroen brands in the European market fell sharply, by 43% and 41%, respectively.

The root of the problem may be related to the lag in industrial policy during the "structural transformation." From the signing of the Paris Agreement in 2015 to the 2035 "ban on internal combustion engines," the EU's clean energy initiatives in the automotive industry have consistently promoted the goal of achieving zero carbon emissions from newly sold vehicles rather than formulating a strategy for the simultaneous electrification of automobiles. This has led to the situation where, although the EU has achieved remarkable results in various fields related to the "green transition" issue, its relatively slow progress in electric vehicle industry policies implemented after 2020, especially when compared to China's major electric vehicle initiatives since 2001, has laid the groundwork for the current and future industrial difficulties faced by the EU automotive industry.

This significant difference resulting from time, technological accumulation, and the degree of industrial layout, while partially serving as the "theoretical basis" for the European Commission to set barriers, has also become a readily available solution for European policy-making bodies to follow. However, eliminating the lack of industrial competitiveness remains a challenge that cannot be accomplished "overnight."

Recently, Valdis Dombrovskis, Executive Vice-President of the European Commission, spoke at the European Parliament on the topic of "The crisis facing the EU automotive industry, potential plant closures, and the need to enhance competitiveness and maintain European employment." He stated that the European electric vehicle market performed weakly in the first half of 2024, with sales growing by only 1%, far below the global average. He also attributed some factors affecting the competitiveness of the European automotive industry to higher energy, labor, and raw material costs, which are about 30% higher in Europe than in China. Meanwhile, although Europe excels in many technological areas, Chinese enterprises have technological advantages in batteries, in-car systems, software, and development timelines.

In response, Dombrovskis stated that the EU will unwaveringly promote the development of electric vehicles and safeguard autonomy in electric vehicle technology. He mentioned that in recent years, the EU has formulated a series of measures to support the development of the electric vehicle market, establishing a complete electric vehicle supply chain including batteries, key raw materials, and semiconductor supply systems, improving charging infrastructure, and accelerating the deployment of power grids suitable for the transition to pure electric vehicles. At the same time, the EU has provided significant funding for the electrification of automobiles, which is used for the transformation of automotive factories and the upgrading of vehicle models. According to the Net-Zero Industry Act, the EU will also train about 100,000 technicians each year to provide manpower support for key areas of green technology in the EU (such as batteries), with the aim of comprehensively improving the skill level of the automotive industry's workforce.

Stronger barriers ≠ enhanced competitiveness

Regardless of the final solution to the anti-subsidy case, one topic seems worth pondering: Will tariffs or price barriers definitely boost the competitiveness of the European automotive industry?

In this regard, Rudy Aernoudt, an EU economist and professor at Ghent University in Belgium, believes that "from an economist's perspective, the solution to trade frictions should not be to block markets but to find avenues for cooperation. If the EU imposes tariffs on Chinese electric vehicles, such a protectionist approach will make European local enterprises lazy and may even cause them to lose their competitiveness. If the market is not opened up and enterprises are not exposed to fierce competition, it may be a good thing for European industry in the short term, but in the long run, it will make it lose competitiveness." Especially in some European countries where industry accounts for only 15% of GDP, and services account for the remaining 85% of the industrial mix, this unsustainable model also limits the tolerance for industrial policy trial and error.