Carl Zeiss Electronic Microscope Technology Cleanliness Solution: Revolutionizing Microscopic Cleanliness for Industrial Quality Enhancement

![]() 02/17 2025

02/17 2025

![]() 600

600

In the vast arena of modern industry, as markets evolve and mature, the bar for product quality standards set by suppliers, manufacturers, and end-users continues to soar, making it a paramount concern for enterprises. Particulate contaminants have emerged as a pivotal factor undermining product efficiency, functionality, and lifespan, thereby jeopardizing overall product quality and performance. Thus, an advanced and efficacious technical cleanliness solution has become indispensable for ensuring the seamless operation of industrial production processes.

Carl Zeiss Electronic Microscope Technology Cleanliness Solution Insight

Carl Zeiss' cleanliness solution, leveraging cutting-edge technology in electronic microscopy, offers robust support for quality assurance in industrial production. It meticulously identifies, analyzes, and reports contamination data, ushering in a new era of production process control. Acting like a precise "technological scalpel," it delves into every nuanced aspect of the production process, revealing hidden contaminant particles in products and accurately quantifying them. More than a mere detection tool, it serves as a potent ally for enterprises to uncover the root causes of contamination and pinpoint the crux of the problem. Furthermore, it significantly expedites the decision-making process, enabling enterprises to swiftly formulate effective response strategies, thereby enhancing product quality.

Carl Zeiss Electronic Microscope Technology Highlights

1. High-Definition Vision in the Microscopic Realm

Whether it's the intricate fine structure of the sample surface or elusive microscopic contaminants, everything is laid bare, leaving no trace hidden.

2. Driving Efficiency with Automation

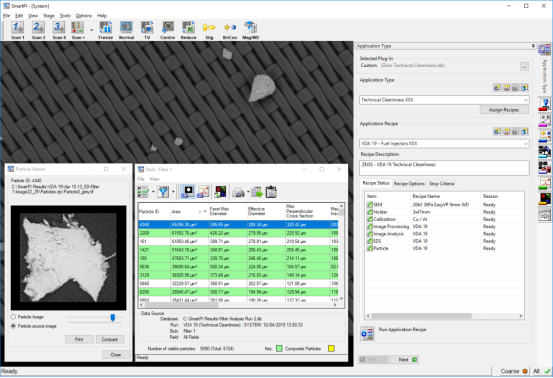

Relying on a fully automated sample analysis workflow, it achieves intelligent automation across multiple critical links. SmartPI seamlessly drives the electron microscope to operational conditions without manual fine-tuning; during prolonged detection, it features an automatic calibration function to ensure data accuracy; during automated detection, it also real-time stitches particles at boundaries to prevent missing details. This simplifies previously complex operating steps, and running the workflow requires no prior knowledge of electron microscopes, thus boosting operators' work efficiency.

3. A Powerful Tool for Streamlined Analysis

Equipped with the robust ZEISS SmartPI particle detection software, it integrates various functions such as controlling the scanning electron microscope (SEM) for particle acquisition, advanced image processing and analysis, and elemental analysis (EDS). It can automatically and efficiently complete particle detection, analysis, and classification tasks, dramatically enhancing work efficiency and analysis efficacy.

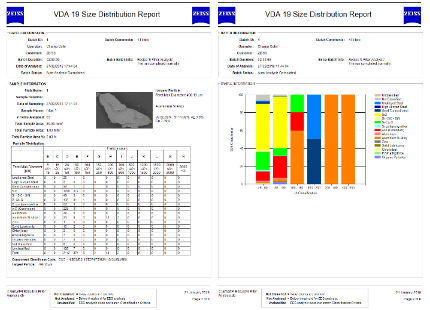

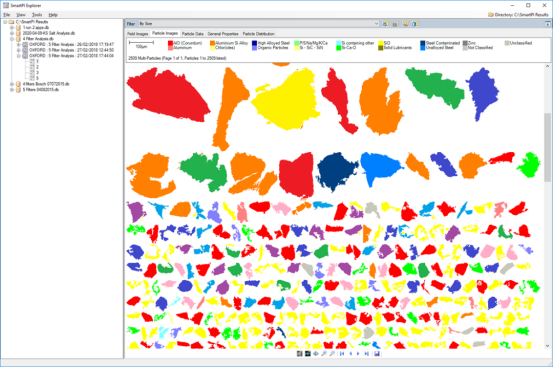

Upon obtaining particle data sets, predefined reports can be generated with a single click through SmartPI Reporter, and users can freely design and create report templates as per their needs. Additionally, the software supports offline independent use, allowing the electron microscope to continue collecting data while reports are being generated. SmartPI Explorer is another highlight, enabling users to independently browse detected particle data, including grayscale and morphological images, sizes, and compositions of each particle, customize particle sorting and filtering conditions, and export data in tabular form.

▲SmartPI Reporter Report Template

▲SmartPI Explorer's Powerful Data Mining Function

▲Capture high-resolution images, analyze, process, measure, and classify

Carl Zeiss Electronic Microscope Product Recommendations

ZEISS EVO

Combining high-performance scanning electron microscopes with an intuitive and user-friendly interface, the ZEISS EVO series stands out as the preferred tungsten filament electron microscope for material analysis and industrial quality assurance. With various optional configurations, ZEISS EVO can be tailored to meet your specific requirements. The EVO series is equipped with a large, high-precision 5-axis electric stage, providing a solid foundation for full membrane scanning and conventional cleanliness analysis. Additionally, ZEISS EVO offers a variable pressure mode (VP mode), enabling direct imaging and analysis of non-conductive samples (such as filter membranes) without the need for sputter coating with a conductive layer.

ZEISS Sigma Series

Harnessing Gemini compound lens technology, the ZEISS Sigma series is a field emission scanning electron microscope renowned for its high-quality imaging and advanced analytical capabilities, making it the ideal choice for users requiring nanoscale cleanliness analysis and higher resolution. The high-resolution imaging provided by the Gemini compound lens is particularly suited for elemental analysis, including magnetic samples.

From the rapidly advancing automotive industry to life-saving medical technology fields; from the aerospace industry delving into the mysteries of the universe to the additive manufacturing sector leading innovation trends, Carl Zeiss' technical cleanliness solutions have achieved extensive and profound applications. Let's collaborate to focus on the realm of microscopic cleanliness and jointly elevate product quality standards.