Quintus HPP Achieves New Breakthroughs in Ultra-High Pressure Processing

![]() 07/15 2024

07/15 2024

![]() 684

684

With the continuous enhancement of global health awareness, the market for cold-pressed juices and health drinks is growing at an unprecedented rate, and it is estimated that the market size will reach US$1.408 billion by 2030. However, along with the prosperity of the market, food safety issues have also become increasingly severe, posing a critical constraint to industry development. Recently, Quintus Technologies, one of the leading companies in the high-pressure field, has brought revolutionary preservation and processing solutions to the juice industry with its HPP (Ultra-High Pressure Processing) technology, achieving preservation without thermal processing while ensuring a perfect balance between nutrition and safety.

Market forecasts indicate that the cold-pressed juice market is continuing to grow at a compound annual growth rate (CAGR) of 8.4%. However, frequent food poisoning incidents have heightened consumers' concerns about food safety. In response to this challenge, the US FDA has issued a series of strict regulations requiring cold-pressed juice manufacturers to follow the Hazard Analysis and Critical Control Points (HACCP) system in production, complemented by Good Manufacturing Practices (GMPs) and Sanitation Standard Operating Procedures (SSOPs), to ensure that harmful microorganisms in the juice are reduced by at least 5-log (i.e., a sterilization rate of >99.999%).

Safeguarding Food Safety: The Microbial Challenge in Cold-Pressed Juices

Although the low pH value (below 4.5) in cold-pressed juices serves as a natural microbial barrier, under specific conditions (such as special acid stress response mechanisms), microorganisms like Escherichia coli, Staphylococcus aureus, yeast, and mold can still survive and multiply tenaciously, thereby shortening the shelf life of the juice and affecting its quality and taste. Therefore, taking effective measures to control microbial contamination is crucial for ensuring juice quality and extending shelf life.

Research shows that if the raw materials for cold-pressed juices originate from complex environments such as the Indian market, the risk of contamination by E. coli and S. aureus increases significantly, reaching approximately 20% and 17%, respectively. These two bacteria are precisely the "culprits" behind many juice-related food safety incidents. Therefore, strictly controlling microbial contamination during production has become a crucial step in ensuring juice safety.

Once a food safety incident occurs, it not only represents a failure in health responsibility for producers but also deals a double blow to brand reputation and economic benefits. Product recalls, damaged brand images, long-term sales declines...a series of chain reactions follow. Furthermore, studies have shown that food safety incidents can lead to significant short-term declines in the share prices of affected companies.

HPP Ultra-High Pressure Processing: The Perfect Balance of Nutrition and Safety

While traditional heat treatment technologies can meet safety standards, they often come at the cost of sacrificing juice's nutritional content. Quintus's HPP technology stands out with its unique non-thermal sterilization mechanism. Unlike traditional methods that rely on heating or chemical additives, HPP technology uses high pressure to directly act on microorganisms such as bacteria, viruses, molds, and yeasts, achieving effective inactivation. This non-heating process perfectly preserves the original flavor, texture, and valuable nutrients of fruits and vegetables, making every sip of juice as fresh as if just picked from the tree. Studies have shown that various nutrients, including flavonoids, vitamins C, D, E, non-flavonoids, anthocyanins, and carotenoids, remain stable during HPP processing.

Quintus Ultra-High Pressure Processing Press – QIF 400L

To address food safety challenges, industry leaders such as Sinomech have taken action, providing customized food safety solutions to Yiqing Foods (one of China's top soft drink producers). Sinomech introduced two high-efficiency HPP systems from Quintus last year, which were deployed in Yiqing Foods' newly built highly automated and modern factory, specifically for its high-end juice production lines, especially for premium orange juice products. The adoption of HPP technology marks an important step forward for the company in ensuring product safety and quality.

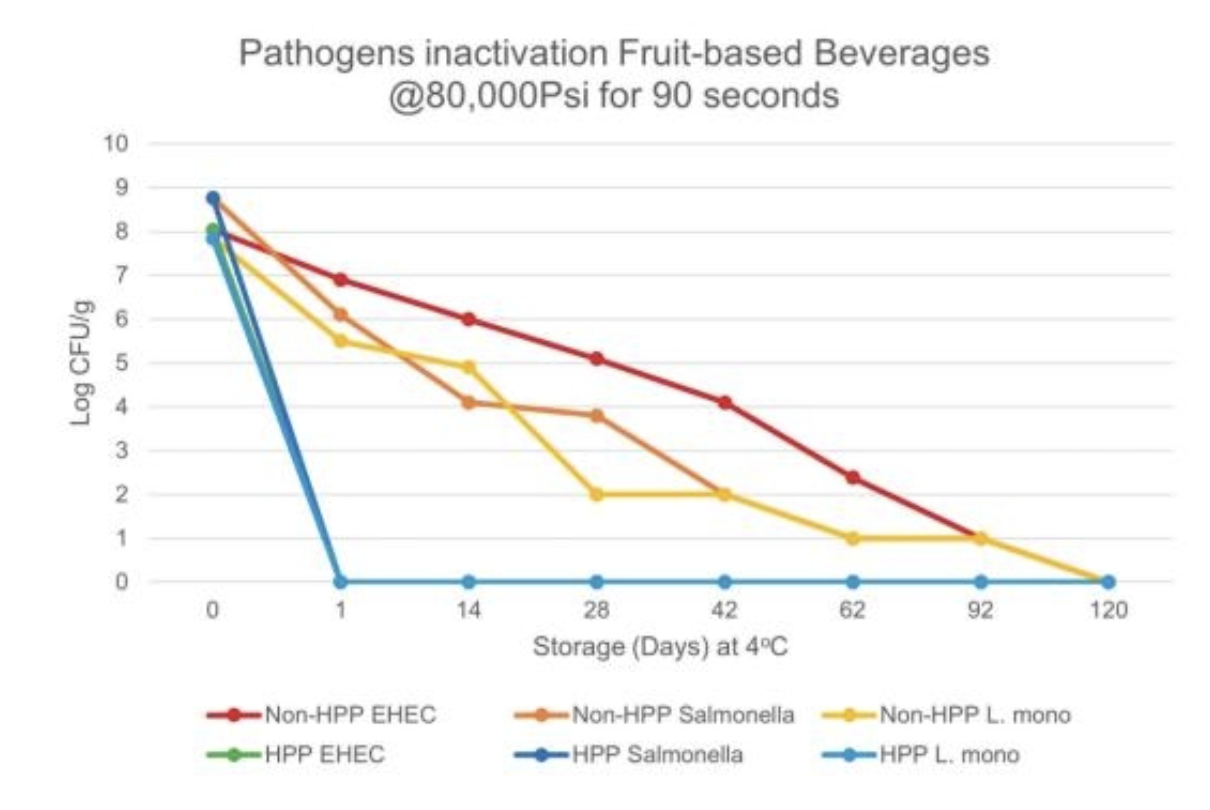

Empirical Research, Quality Assurance

At Quintus's HPP Application Center in Columbus, Ohio, USA, the research team verified the exceptional efficacy of HPP on juices/health drinks through microbial challenge studies. Over a 120-day period, researchers monitored the bacterial content in HPP-treated juices and compared it to untreated juices. The results showed that in the untreated control samples, bacterial content gradually decreased over time due to the acidic environment, as illustrated in the figure below.

HPP processing inactivated the inoculated pathogenic bacteria, with no regrowth observed throughout the testing period.

In the HPP-treated samples, whether the treatment time was 90 seconds or 120 seconds, no pathogenic bacteria were detected. The process completely inactivated the bacteria, and no regrowth was observed within 120 days. The experiment clearly demonstrated that HPP processing successfully reduced the content of inoculated pathogenic bacteria in the tested juices by more than 5-log (sterilization rate >99.999%), meeting the FDA's requirement for a 5-log reduction in pathogenic bacteria content as specified in the "Fruit and Vegetable Juice HACCP Regulation" (21CFR 120).

Looking Ahead, Building Health Together

The introduction of HPP technology not only addresses the hidden concerns of cold-pressed juices in terms of food safety but also retains the rich vitamins, enzymes, minerals, and other nutrients in the juice. Through the application of this technology, producers can effectively control microbial contamination, ensuring the safety and quality of juice products. At the same time, it will also help producers enhance their brand image and win the trust and favor of consumers. For consumers pursuing a healthy lifestyle, this is undoubtedly a great blessing.

In the future, with the continuous promotion and popularization of HPP technology, the juice industry will usher in even broader development prospects. As a leader in HPP technology, Quintus will continue to commit to technological innovation and quality improvement, providing safer and more efficient solutions for juice and health drink producers.