World Premiere! Hoyer Introduces Revolutionary Energy-Saving System (ESS) to Slash Ship Emissions and Fuel Costs – Achieving Up to 65% Energy Savings

![]() 03/25 2025

03/25 2025

![]() 900

900

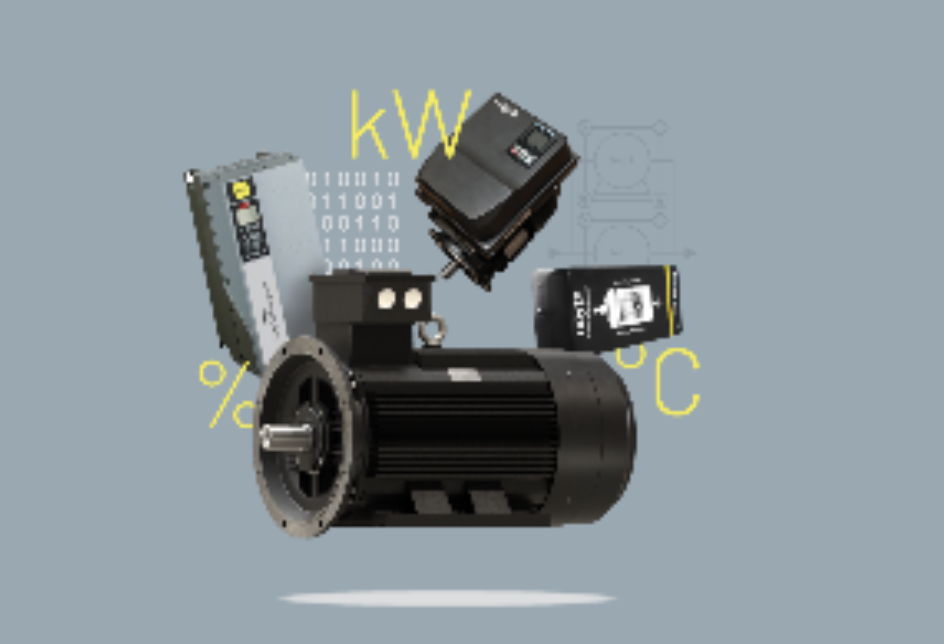

March 25, 2025 – Hoyer, a pioneer in high-performance motors and automation solutions, will unveil its groundbreaking Energy-Saving Systems (ESS) at the Sea Asia exhibition in Singapore. Tailored for retrofitting operational ships, this system employs dynamic intelligent control technology to cut motor energy consumption by 40%-65% without the need for drydocking, offering a potent solution for the shipping industry's green transformation.

Amidst tightening environmental regulations such as the EEXI, CII, and the International Maritime Organization's (IMO) 2050 decarbonization goals, coupled with surging fuel costs, shipowners and operators are under pressure to enhance ship energy efficiency. Hoyer's ESS integrates variable frequency drives (VSDs), intelligent sensors, and automation technology to provide real-time control over essential equipment like engine room fans and seawater/freshwater cooling pumps. This not only drastically reduces energy consumption and fuel costs but also minimizes carbon dioxide (CO2), sulfur oxide (SOx), and nitrogen oxide (NOx) emissions, prolongs equipment lifespan, and supports the shipping industry's sustainable development goals.

ESS Core Advantages

- Average Energy Savings: 40%-65% through dynamic control of fans, pumps, and other equipment

- Environmental Benefits: Reduced fuel consumption, with up to 628 tons of CO2 emissions annually per ship, concurrent SOx and NOx emission reductions, aligning with CII and EEXI regulations.

- Quick Return on Investment: Typically less than 2 years

- No Operational Downtime: Installation does not disrupt normal ship operations – no drydocking required

- Rapid Deployment: Supports installation during ship operations with no downtime, from assessment to delivery in just 15 weeks.

Technological Breakthrough: Dynamic Adjustment for Precise Energy Savings

The ESS system combines variable speed drives (VSDs), high-precision sensors, and intelligent control algorithms to monitor the ship's operating environment (e.g., temperature, pressure, load) in real-time and dynamically adjust the speed of pumps and fans, eliminating energy waste associated with traditional "one-size-fits-all" approaches. Its core applications include:

- Engine Room Fans: Automatically adjust speed based on ambient temperature, reducing energy consumption by up to 50%;

- Seawater Cooling Pumps: Adapt to varying water temperatures and sailing conditions, achieving energy savings of 50%-65%;

- Low-Temperature Freshwater Cooling Pumps: Match cooling water flow based on real-time demand, saving 40%-50% of energy.

Furthermore, the ESS seamlessly integrates with the ship's Alarm Monitoring System (AMS) and Condition Monitoring System (CMS), offering a real-time data visualization interface and enabling remote upgrades and maintenance via the cloud to ensure long-term efficient system operation.

Palle Grankvist

'Hoyer's ESS is not merely a standard control system but a unique and scalable retrofit solution delivering tangible, measurable results,' said Palle Grankvist, Global Business Development Manager for Automation Solutions at Hoyer. 'Shipowners currently need solutions that are easy to implement, offer quick returns on investment, and provide immediate operational and environmental benefits. Hoyer's ESS was designed specifically for this purpose.'

Business Impact: Payback in 2 Years with Significant Emissions Reduction

A case study of a European shipowner reveals that after installing the ESS, annual electricity savings exceeded 1.41 million kWh, fuel consumption was reduced by 290.5 tons per year, resulting in direct savings of approximately $169,000 annually, with a payback period of just 1.65 years. Specific achievements include: 49% energy savings for engine room fans, 54% for seawater cooling pumps, and 40% for freshwater cooling pumps. The environmental benefits are equally remarkable: 628.4 tons of CO2 emissions reduced annually; 12.1 tons of SOx and 20.1 tons of NOx reduced annually.

About Hoyer

With over 50 years of technological leadership in the global maritime sector, Hoyer has been committed to driving the industry's green transition through innovative, customized motor solutions. Its ESS system has been successfully deployed on various ship types, helping shipowners meet the IMO 2050 emission reduction targets and address the challenges of energy efficiency indicators such as EEXI and CII.

For more information about Hoyer's ESS, please follow the official WeChat public account 'Hoyer Motor' or visit the Hoyer official website to download the ESS whitepaper.