How Huawei Pioneers the Transition from 'Made' to 'Smart Made' in the Manufacturing Industry!

![]() 12/13 2024

12/13 2024

![]() 574

574

Amidst rapid technological advancements, the manufacturing industry is undergoing a profound transformation. Digitalization and intelligentization are akin to a potent eastern wind sweeping through every corner of the industry, marking a pivotal step forward. In this monumental shift, Huawei has not only achieved self-improvement but also embraced the challenges of the digital intelligence era with courage.

Recently, Huawei's China Enterprise Business Group hosted a smart manufacturing media communication conference in Chongqing, centered on the theme "Digital and Smart Manufacturing: One Touch Away." Yang Ping, General Manager of Huawei's China Enterprise Business Group's Smart Manufacturing System Department, presented Huawei's latest insights and practices in smart manufacturing. She detailed how Huawei leverages digitalization and intelligentization to spark innovation within the manufacturing sector. Huawei's three decades of expertise in ICT and digital transformation have transformed into a potent force driving external services, enabling the company to navigate the challenges and opportunities of intelligentization alongside its manufacturing clients.

Yang Ping, General Manager of Huawei's China Enterprise Business Group's Smart Manufacturing System Department

Innovation in Huawei's Manufacturing DNA and Digital Transformation

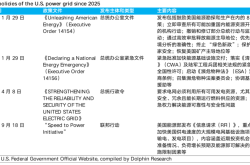

Amid the global wave of manufacturing transformation, Huawei, as a manufacturing enterprise with robust R&D capabilities, embarked on building an information system in the 1990s. From Integrated Product Development (IPD) process management to Integrated Supply Chain (ISC) management, and ultimately to the comprehensive digital transformation initiated in 2014, Huawei has progressively achieved a leap from 'data connection' to 'intelligent empowerment'.

In practice, Huawei has established a full-factor connection and real-time feedback system, achieving real-time integration and analysis of over 6 million devices worldwide, covering more than 40 communication protocols and over 100 manufacturer devices. This foundation enables real-time production data visualization and decision optimization, implements data governance, and ensures data security through established protocols.

The results of this transformation are glaringly evident, reflected in substantial revenue growth and a moderate increase in employee count. Revenue soared from nearly RMB 400 billion in 2015 to RMB 890 billion in 2020, while the employee headcount rose by merely 10%, underscoring the efficiency gains stemming from digitalization.

Spillover Capacity: Empowering Diverse Industries

Spurred by the wave of artificial intelligence, straightforward digital transformation can no longer meet the rapid development needs of enterprises. Huawei keenly recognized this shift and comprehensively launched an AI strategy in 2018, deeply integrating the benefits of intelligentization and digitalization to pave the way for future growth.

Under this strategy, Yang Ping showcased Huawei's collaboration efforts in the automotive, pharmaceutical, and robotics industries, fully illustrating Huawei's significant achievements in the digital and smart transformation process.

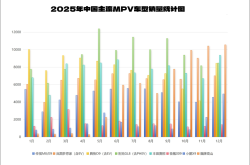

Globally, the automotive industry stands as the world's largest industrial sector, often referred to as the 'backbone' of manufacturing. Leveraging its profound strength and extensive experience in manufacturing digital and smart transformation, Huawei aids automotive enterprises in connecting engineering data flow, business information flow, and production supply flow, facilitating seamless data flow within factories and enabling on-demand production participation. By realizing the visualization and controllability of the production process, it substantially enhances automation rates and equipment intelligent maintenance levels, strengthens quality traceability and optimization capabilities, optimizes energy consumption management, and markedly boosts corporate competitiveness. The partnership between Huawei and automakers like Changan is a powerful testament to this approach.

Huawei has also expanded its digital and smart transformation capabilities into niche areas of the manufacturing industry. For instance, in the robotics sector, Huawei has revamped the structured R&D process of enterprises through the IPD method, significantly improving the stability of R&D and manufacturing while effectively reducing R&D costs. In the biomedical field, Huawei utilizes the Pangu large model for pharmaceutical molecules and leverages AI's robust computing and simulation capabilities to assist pharmaceutical companies in achieving remarkable breakthroughs in drug molecule structure discovery, clinical trials, and gene characteristic analysis, substantially shortening the drug development cycle and accelerating the pace of innovation.

Furthermore, to anchor smart manufacturing, Huawei is actively promoting the cultivation of digital and smart talents. Huawei has also partnered with industry-university-research collaborations, joining forces with over 72 universities and more than 7,500 manufacturing enterprises to jointly propel the digital and smart transformation of the manufacturing industry, encompassing multiple domains such as automobiles, equipment manufacturing, biomedicine, and home appliances.

Final Thoughts

Yang Ping emphasized that Huawei aims to empower every manufacturing enterprise with digital and smart capabilities, contributing to China's transformation from a manufacturing powerhouse to a manufacturing superpower. Huawei's commitment is unwavering. Adhering to the value proposition of 'Deepening Manufacturing and Enabling Smart Manufacturing,' Huawei will continue to delve into technology, experience, and ecosystem, providing robust support for the digital transformation and intelligent upgrading of the manufacturing industry.

Moving ahead, while collaborating with more manufacturing enterprises to set industry benchmarks, Huawei will also replicate and extend these successful practices to additional manufacturing sub-sectors, aiding manufacturing enterprises of varying sizes and types in innovating their operational and business models through digital and smart empowerment, unleashing new productive forces, and fostering high-quality development in the manufacturing industry. Let us anticipate China's manufacturing industry striding forward on the path of digital transformation and intelligent upgrading, embracing an even brighter future under Huawei's guidance.