Solution | Revolutionary Advancement in 5nm: EVOC Intelligent Accelerates the Efficient Development of Semiconductor Enterprises!

![]() 12/18 2024

12/18 2024

![]() 519

519

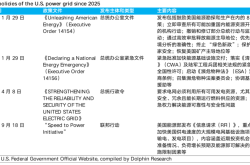

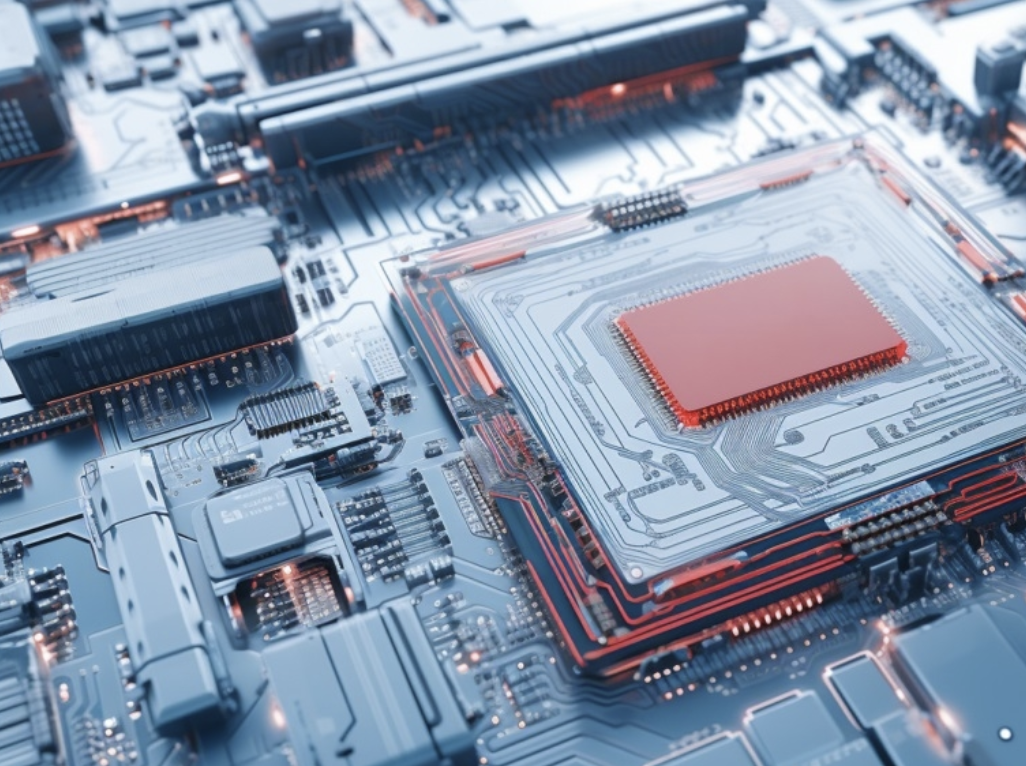

Recently, domestic chips have made a groundbreaking achievement in advanced 5nm process technology, poised for mass production! This marks a significant milestone, indicating that China's chip industry has officially breached Western technological barriers and achieved a remarkable turnaround! To support the intelligent and efficient growth of semiconductor enterprises, EVOC Intelligent has introduced a groundbreaking solution tailored for the semiconductor industry, precisely bolstering semiconductor process production inspection.

The sophistication and intelligence of production and manufacturing systems have undeniably emerged as a pivotal strategy for semiconductor manufacturers to bolster their competitiveness. The implementation of industrial tablets provides robust guarantees for the production management and process control of semiconductor enterprises.

1. Industry Challenges

Currently, the semiconductor industry grapples with the following three primary challenges:

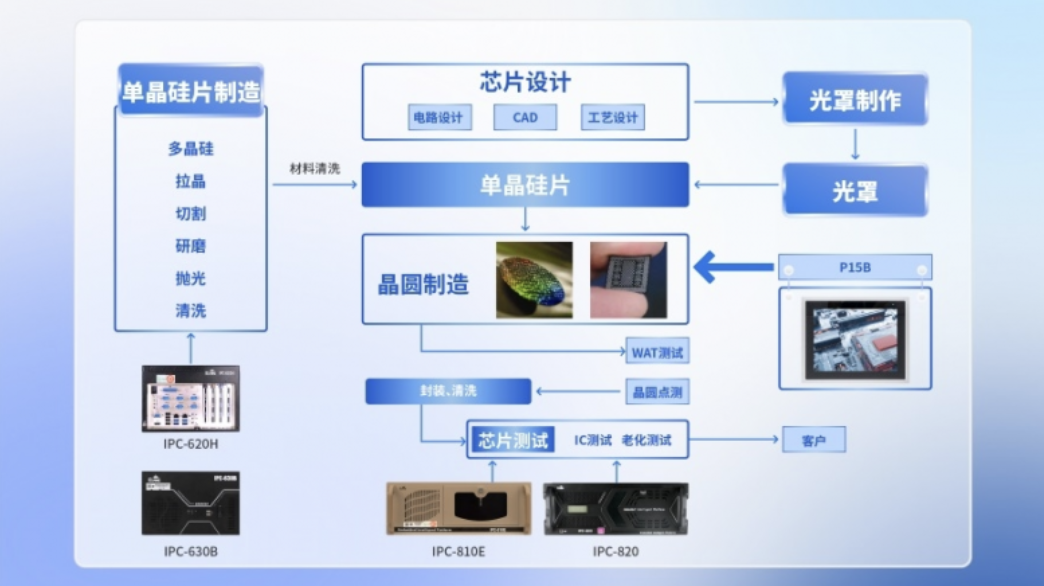

1. Complex Production Processes: The semiconductor production lifecycle encompasses numerous stages, including wafer preparation, chip processing, packaging, and testing, each necessitating rigorous control and management.

2. Quality Assurance Difficulties: The semiconductor production process involves the meticulous control of numerous procedures and parameters, making it challenging to ensure product quality. Consequently, defect rates are high, necessitating comprehensive production process control and monitoring.

3. Production Planning and Scheduling Hurdles: Given the multiple stages of production planning, it is difficult to orchestrate and allocate production resources, equipment, and personnel effectively, thereby complicating the timely completion of production plans.

2. Star Solution

Semiconductor inspection is a vital aspect of the manufacturing process, with its quality and reliability directly impacting the final product's performance. EVOC Intelligent's star industry solution, leveraging the P15B industrial tablet, offers efficient and precise solutions tailored to semiconductor customers.

Solution for Semiconductor Industry Production Process Control

EVOC Intelligent's P15B features a 15-inch touchscreen and robust computing capabilities, complemented by a Xeon processor, enabling the real-time processing of extensive data volumes and enhancing inspection efficiency.

In real-time monitoring of various facets of the semiconductor manufacturing process, the P15B swiftly identifies and rectifies issues through data feedback and analysis, ensuring each chip adheres strictly to specifications, thereby bolstering production line stability and product quality.

Furthermore, integrating machine vision systems, sensors, and other equipment with the P15B facilitates faster and more accurate semiconductor product inspection, minimizing human intervention.

Customer Benefits

In operation, EVOC Intelligent's P15B effectively ensures production efficiency and product quality for customers. The solution's three core advantages significantly enhance the core competitiveness of semiconductor manufacturing enterprises.

1. Elevate Overall Operational Standards: Semiconductor enterprises can swiftly and accurately manage their investment costs and profitability, aiding in cost savings, earnings improvement, and continuous strengthening of core competitiveness.

2. Prompt Production Plan Adjustments: Enterprises can swiftly adapt to market demands, promptly and precisely adjusting production plans, significantly reducing inventory levels, and optimizing enterprise resource utilization.

3. Effective Product Manufacturing Process Monitoring: Detailed records of the product manufacturing process, coupled with corresponding enterprise prompts, enable seamless control over the manufacturing process, minimizing manufacturing errors, and drastically improving production efficiency.