Revolutionary 164 Degrees of Freedom: Introducing the Human-Like Robot

![]() 12/27 2024

12/27 2024

![]() 584

584

Author | Xiang Xin

In 1973, the film "Westworld" premiered, captivating audiences worldwide. In 2016, an American TV series adaptation of the same name gained global popularity.

The bio-robots in both works have collectively become the quintessential representation of futuristic sci-fi worlds for generations.

Fifty-one years later, the plot of the film has materialized with the advent of a humanoid robot designed entirely based on human reference samples.

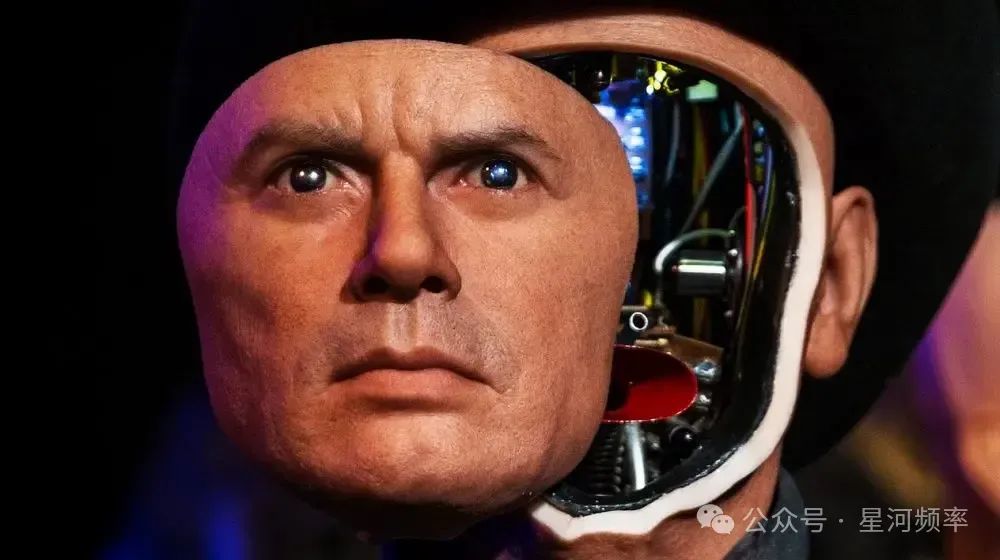

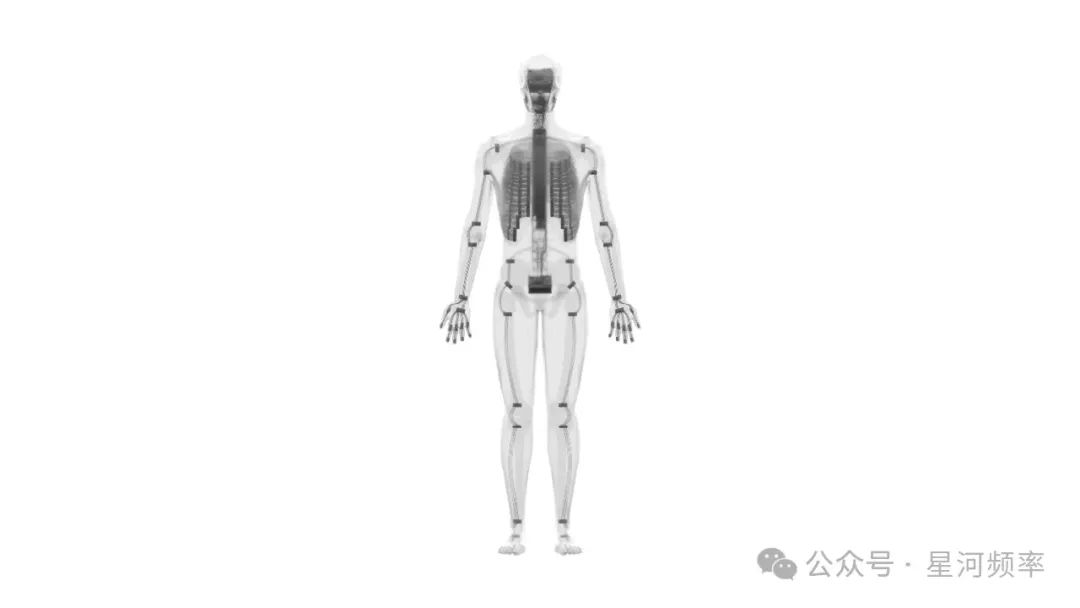

This bio-robot, named Clone Alpha, replicates human anatomy on a 1:1 scale, comprising artificial muscles, carbon fiber synthetic bones, and hydraulic pipelines mimicking human blood vessels, all encased in a layer of white film binding muscles and bones.

Developed by Clone Robotics in Poland, this humanoid robot boasts 164 degrees of freedom in its upper body alone, surpassing the 10-60 degrees of freedom found in other humanoid robots currently on the market, making it the world's most flexible humanoid robot.

While most companies worldwide simplify human anatomy to create humanoid robots, Clone has taken a different approach, replicating human flexibility and strength by mimicking human anatomy.

This is a highly innovative method.

Unlike Clone, which employs hydraulic drive and a bionic design inspired by human muscles and bones, most robotic enterprises use electric motor drive combined with linear/rotary actuators and mechanical housings.

This design allows Clone Alpha to have almost no rigid metal parts throughout its body, granting it flexibility. Additionally, due to its artificial muscles and powerful hydraulic system, Clone Alpha possesses sufficient strength.

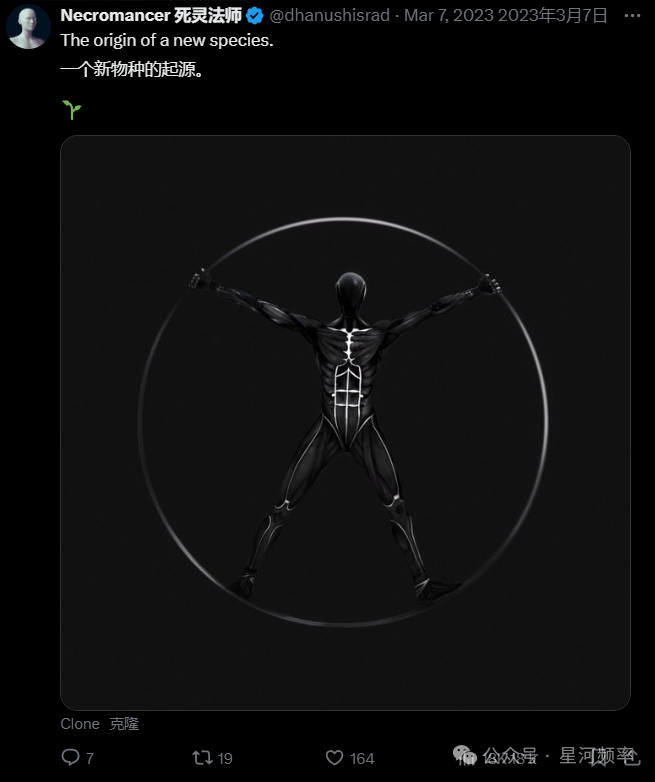

Clone's founder, Dhanush Radhakrishnan, stated that Clone's design enables robots to achieve human-level degrees of freedom, meeting the requirements of strength, rapid response, and durability, all at a significantly lower design cost compared to other robots.

This bold and innovative company aims to create a new species at a lower cost than its peers.

Statement by Clone Founder Dhanush Radhakrishnan

Ultra-high degrees of freedom, human-level muscular capability

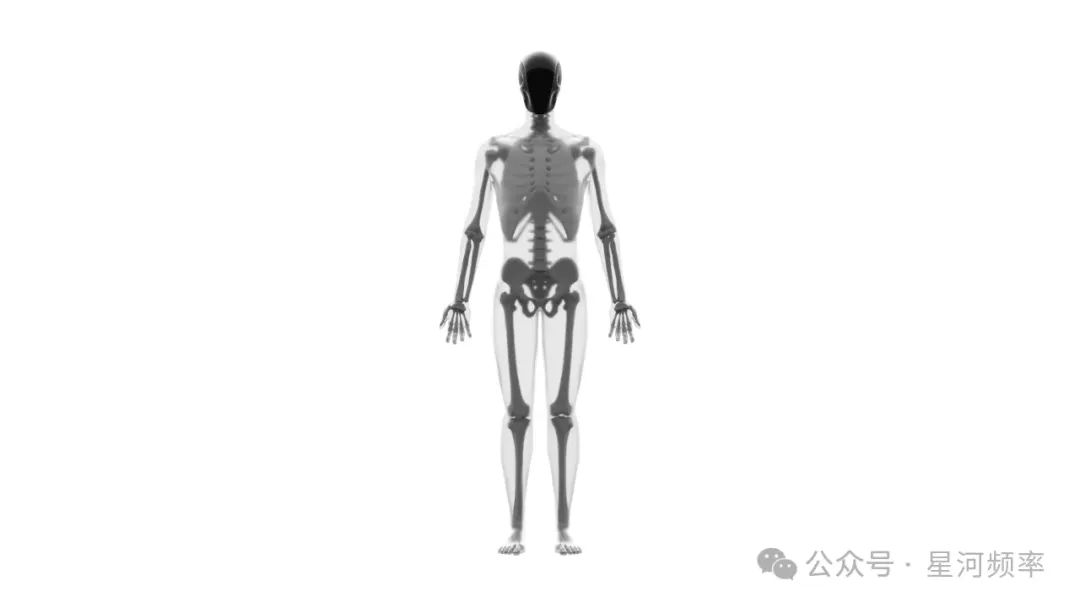

Clone Alpha's biomimicry is evident in its synthetic organ systems, including bones, muscles, blood vessels, and a nervous system, analogous to those of humans.

Replicated based on human bones, Clone Alpha possesses a significantly higher degree of freedom than other humanoid robots.

Clone Alpha's skeletal system comprises 206 bones, the same number as humans, with a few bones fused together. It has bones shaped like human spines, ribs, pelvises, and collarbones.

Its joints are connected by artificial ligaments and connective tissues. The four joints in the shoulders have a total of 20 degrees of freedom, each vertebra in the spine has 6 degrees of freedom, and the hands, wrists, and elbows have 26 degrees of freedom.

In kinematics, the human body has 244 degrees of freedom, whereas Clone Alpha alone has 164 degrees of freedom in its upper body.

Moreover, these artificial bones are made from inexpensive and durable polymers.

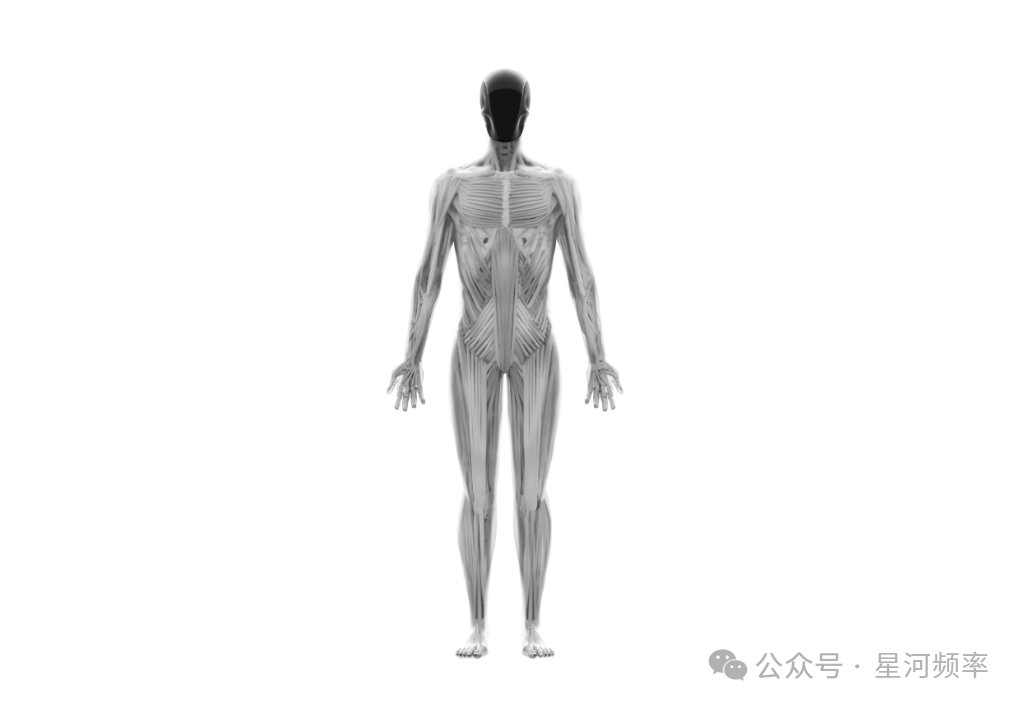

Bones serve as the framework, while muscles provide the motive force. Clone Alpha's muscles contract faster than human muscles.

Clone uses its own artificial muscle, Myofiber, developed in 2021, with each tendon precisely connected to the corresponding position on the bone according to anatomical standards.

This artificial muscle responds extremely quickly, contracting by 30% within 50 milliseconds and exhibiting excellent load-bearing capability, with 3g of muscle fiber capable of generating at least 1kg of contraction force, supporting or moving objects weighing at least 1kg.

Clone claims that Myofiber is the world's only artificial muscle that perfectly combines weight, power density, speed, force-to-weight ratio, and energy efficiency.

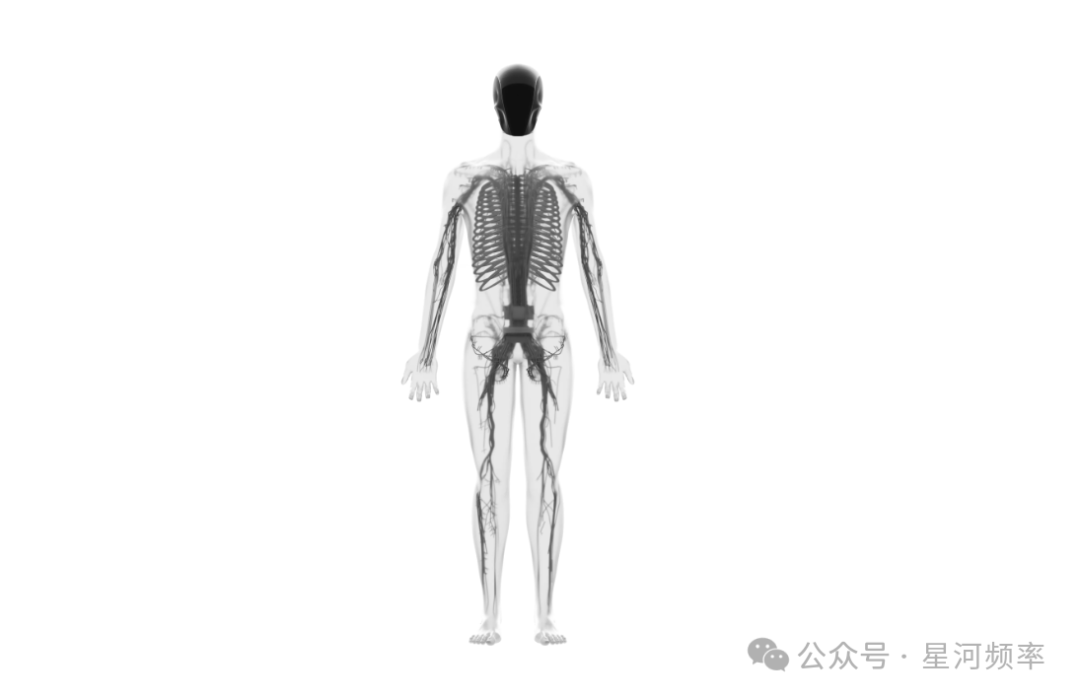

Clone Alpha's vascular system is driven by a 500W electric pump and hydraulic actuator valves.

The electric pump, installed at the center of the robot's torso, acts as the robot's heart, capable of pumping 40 liters of fluid per minute at a rated pressure of 100 psi (pounds per square inch).

Clone's Aquajet hydraulic valve can deliver 2.28 liters of fluid per minute at 100 psi with a power consumption of less than 1W.

Clone Alpha's nervous system primarily relies on cameras in its skull and sensors throughout its body.

This robot only has proprioception and vision, lacking pressure, temperature, and pain sensations (proprioception refers to the body's awareness of the position, direction, speed, and weight of its own limb movements).

Four depth cameras are installed in the robot's skull to provide visual information.

Seventy inertial sensors provide joint proprioception, while 320 pressure sensors provide muscle-level force feedback.

A microcontroller installed in the robot's vertebrae serves as a neural information transfer and control station.

It has three functions:

Receiving sensor feedback;

Controlling hydraulic actuator valves;

Sending and receiving information to and from the NVIDIA Jetson Thor inference GPU in the skull at extremely high speeds.

The GPU in the skull runs Clone's "Cybernet" visual-motor foundation model, capable of processing data fed back from various parts of the body.

Despite Clone Alpha's impressive hardware capabilities, it has yet to demonstrate intelligent abilities.

The current codename "Alpha" signifies that it is still an early development version.

To enhance the robot's intelligence, Clone is assembling a robotic intelligence team in the United States, recruiting engineers with experience in multimodal large language models, 3D vision, and the development of control-centric world models.

Taking an unconventional path, creating a robot with just $500,000

If Clone could be described in one sentence, it would be: taking an unconventional path.

Clone stands out in two main ways.

The first distinction is that while other humanoid robot companies focus on solving mobility issues, Clone chooses to address manipulation issues first.

In other words, while others start with the robot's bipedal locomotion, Clone begins with the development of the robot's dexterous hands.

Clone's founder and CTO, Łukasz Kolik, believes that hand design and manufacturing are the most challenging yet valuable aspects of the entire robotics industry.

From 2016 to 2021, Łukasz Kolik studied at the Faculty of Mechanical Engineering of Poland's top polytechnic university, Wroclaw University of Technology. The development of dexterous hands spanned his entire university career.

He spent seven years developing musculoskeletal robotic technology, designing valves for hydraulic drives, and durable artificial muscles.

In subsequent iterations, the Clone Hand achieved a maximum of 27 degrees of freedom, surpassing that of human hands. The current version has been simplified to 24 degrees of freedom, capable of performing all actions a human hand can, including bending, gripping, and rotating the wrist forward and backward.

Clone's second distinction lies in its ability to create a humanoid robot with significantly fewer funds and resources than its peers.

Clone's other founder and CEO, Dhanush Radhakrishnan, is the primary driver behind Clone's commercialization and product intelligence.

Dhanush studied mathematics at New York University in the United States and has made contributions in the fields of plasma physics, reinforcement learning, and venture capital.

He has published papers in the physical science journal Nuclear Fusion, developed a symptom checker capable of detecting 655 diseases based on reinforcement learning technology, and was a member of the graduating team of the renowned American startup incubator Y Combinator's summer class of 2019, raising over $2 million in venture capital funding.

In 2020, he noticed Łukasz Kolik's robotic hand project and decided to join forces, bringing the product to market, expanding production scale, and endowing it with an intelligent brain.

After Clone was founded, it only raised $650,000 in its angel round.

But this slightly meager funding didn't delay the robot's development. Clone Hand has iterated from the 11th generation to the 18th, and has also improved the hydraulic system and muscles, increasing its load capacity from 7kg to 30kg.

During Clone's crowdfunding campaign in 2022, Dhanush emphasized that Clone might be the robot company with the highest capital utilization rate at the time. Competitors spent tens of millions to hundreds of millions of dollars on developing robot technology, while they only spent $500,000.

Although Clone raised an additional $6.5 million in its subsequent seed round, bringing their total funding to $7.15 million (approximately RMB 52.09 million).

However, compared to other humanoid robot companies, this amount of money is not substantial.

For example, Agility Robotics has raised $328 million (approximately RMB 2.39 billion), and Figure AI has raised $750 million (approximately RMB 5.26 billion).

Clone's team is also not large, with only 12 employees in 2023 and currently 23 employees.

The low funding is likely due to Clone being a startup based in Poland, which is limited by geography and talent levels.

The two founders also did not have previous successful entrepreneurial experiences, and the company has not yet launched intelligent products to attract large investors.

But this may change with the emergence of Clone Alpha.

Clone Alpha's exceptional hardware capabilities mean that Clone has crossed the first hurdle in robot development, possessing its first moat.

In fact, Clone's headquarters in Poland also has its advantages. Labor and material manufacturing costs are lower in Poland, making the production and development costs of robots much lower than in the United States.

Currently, all movements demonstrated by Clone robots are manually programmed. But Clone is also pushing forward the intelligence process of robots.

At the end of October this year, Clone brought in Viktor Makoviichuk, co-founder of NVIDIA IsaacGym, as the company's Chief Scientist.

IsaacGym is a GPU-based high-performance physics simulation environment primarily used for robot learning.

Viktor Makoviichuk's joining may significantly enhance the intelligence level of Clone robots.

Has Clone solved the

Hydraulic equipment is prone to damage and loss of power, with the complexity and high precision of parts leading to high costs and maintenance challenges. Additionally, the system's overall energy efficiency is suboptimal, and noise levels are elevated.

Boston Dynamics' hydraulic Atlas model, costing upwards of $2 million, boasts impressive acrobatic feats like backflips and parkour, yet its battery life is limited to just 1.5 hours.

In contrast, electric motor humanoid robots, such as Tesla's Optimus, offer a battery life of approximately 5 hours, while Agility Robotics' Digit can achieve an impressive 16 hours under optimal conditions.

However, Clone appears to have addressed the issues of high manufacturing costs, susceptibility to damage, power loss, and excessive noise commonly associated with hydraulic robots.

Firstly, the carbon fiber skeleton utilized by Clone is both robust and economical, retailing at just $97.50 on Amazon.

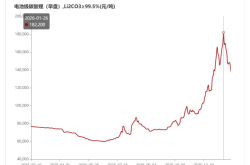

Secondly, Clone asserts that their hydraulic tubing, or muscle fibers, cost merely $10 per meter.

The Clone robot's entire body will primarily comprise polymers, a material that Clone introduces as easy to work with and cost-effective, enabling rapid and economical robot production.

Moreover, even if Clone's hydraulic tubing sustains damage, it can continue to operate normally.

In the GIF, despite being punctured multiple times with a pin, the muscle fibers contract normally without losing power.

What sets Clone apart is its use of water as the hydraulic medium.

Previously, the Atlas's hydraulic version employed hydraulic oil, which is not easily sourced, challenging to clean up in case of leaks, and environmentally harmful. Water circumvents these drawbacks.

Regarding sound, Clone's water pump operates at 36 decibels, akin to the quiet ambiance of a library.

Compared to other hydraulic humanoid robots, Clone's models stand out for their quietness, lightness, and relatively low manufacturing costs.

In terms of battery life, Clone also has ambitions. Dhanush revealed the company hopes the robot can work in two shifts, operating continuously for 16 hours without needing a recharge.

Currently, Clone Alpha is available only as an upper body prototype, lacking legs.

Clone announced plans to soon equip the robot with legs and pre-sell 279 Clone Alphas next year.

Clone Alpha Walking Demonstration

Clone's next-generation robot, Neo, is currently under development.

In the future, Clone intends to preload 16 household task skills onto the robot, encompassing activities like making sandwiches, folding clothes, installing washing machines, and autonomous charging. Additionally, the robot will be equipped with a Telekinesis (mind control) training platform, empowering users to teach the robot new skills independently.

Łukasz Kolik, Clone's CTO, stated that by 2026, Clone robots will be capable of performing the aforementioned functions.

Can Clone swim against the tide and carve its own path? The answer remains unknown.

Yet, for the humanoid robot industry, every glimmer of innovation holds the potential to shine brightly.