iPhone Affordability in Jeopardy: Americans Face 104% Tariffs

![]() 04/09 2025

04/09 2025

![]() 471

471

Trump's actions are indeed unprecedented. Enraged by China's countermeasures, he has imposed an additional 50% tariff on Chinese goods.

According to these calculations, goods originating from China now face a cumulative tariff of 20% + 34% + 50%, amounting to a staggering 104% to enter the US market—a historic high.

This tariff hike underscores Trump's desperate attempt to prove a point.

A 104% tariff rate is unsustainable for any company involved in international trade. No business can absorb such a cost, whether by internalizing it, passing it down the supply chain, or transferring it to consumers.

Neither companies nor their supply chains can operate with profit margins exceeding 100%. Therefore, at this juncture, additional tariffs of 100%, 1000%, or even 100,000% are merely symbolic and devoid of practical meaning.

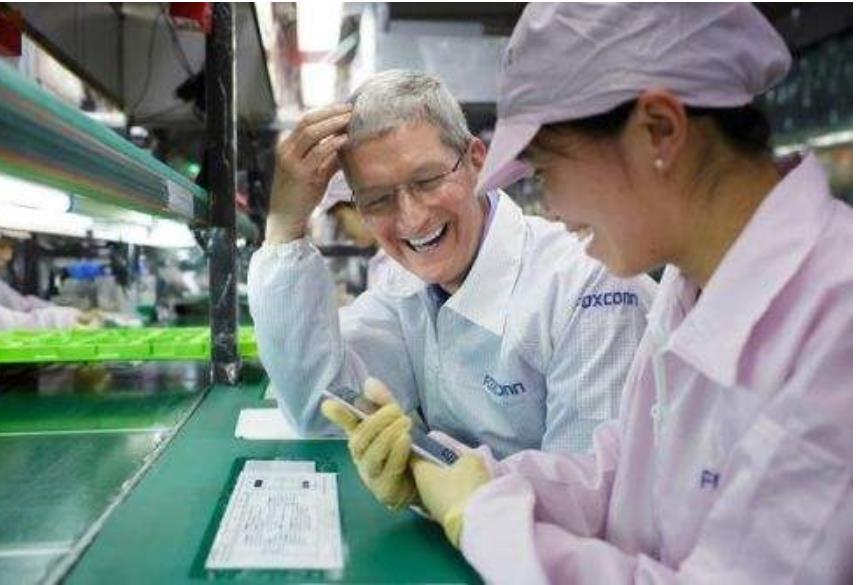

Upon the announcement of this tariff policy, many observers noted that Americans may soon find iPhones unaffordable. Given that iPhones hold a 50% market share in the US, what will consumers do next?

Why can't Americans afford iPhones anymore? At least 85% of iPhones are manufactured in China, and importing them into the US now incurs a 104% tariff. This scenario is economically unviable.

Currently, an iPhone 16 Pro retails for approximately $1000 in the US market, with a hardware cost of around $550. Applying a 104% tariff to this cost price would increase the cost per phone by over $550, bringing the total cost to $1100—higher than the original selling price.

If Apple aims for a profit, with a gross profit margin of at least 20%, the selling price would have to rise to $1400 to potentially break even.

Compared to the previous price of $1000, the new price of $1400 represents a more than 40% increase.

Some may argue that the US's objective is straightforward: to compel companies like Apple to manufacture in the US to avoid tariffs. However, for Apple, manufacturing is not the sole issue; its raw materials, components, and much of its supply chain also originate from China. Data reveals that 157 out of Apple's top 200 supply chain enterprises have factories in mainland China. Even if iPhones were manufactured in the US, relocating over 100 supply chains would be an arduous task.