Internal Combustion Engines Surpass Electric: What's Mercedes-Benz Up To?

![]() 07/03 2024

07/03 2024

![]() 684

684

For many automakers, it's all in on new energy, but for giants like Mercedes-Benz, they are now starting to experiment with diversifying their approach. Recently, the CEO of Mercedes-Benz revealed that this year's investment in internal combustion engine technology has exceeded previous investment plans. Two key points were highlighted: one is to upgrade the transmission system of its hybrid vehicles to ensure sustainability for the next decade; the other is to revamp the internal combustion engine version of the flagship Mercedes-Benz S-Class. In essence, Mercedes-Benz's new internal combustion engine project covers a comprehensive upgrade of both engines and transmissions. Additionally, Ola Källenius added that without these efforts, Mercedes-Benz's internal combustion engine business would stagnate between 2027-2028. What prompted Mercedes-Benz to make such a bold, if somewhat exaggerated, statement? And in which direction will Mercedes-Benz's new generation of internal combustion engine systems evolve?

The Intense M254, Ready to Become the Best Plug-in Hybrid?

Engines are not components that undergo frequent iterations, but the widely used M254 engine marks the introduction of three generations of power systems by Mercedes-Benz over the past eight years. In 2012, the M274 engine replaced the six-cylinder naturally aspirated engine with a four-cylinder turbocharger. This was undoubtedly a move in line with the changing times, but just six years later, Mercedes-Benz realized that the times might still be evolving, and turbocharging was not the end. In 2018, the Mercedes-Benz M264 was born, equipped with 48V mild-hybrid functionality. Judging from the introduction of the current M254 engine just two years later, it's not an exaggeration to say that the M264 was a transitional product. Its greatest significance lies in helping Mercedes-Benz quickly grasp the trend of electrification following its success with turbocharging.

If we broaden our perspective, from the M274 engine 12 years ago to the M254 engine four years ago, Mercedes-Benz has actually been focused on one goal: using electrification to address the efficiency issues of turbocharged engines. As a result, we can see that components ranging from the oil pump to the air-conditioning system, and even some turbocharger models, have become electrified. However, this also means that for over a decade, Mercedes-Benz's internal combustion engine division has been standing on the foundation of the M274 engine. The most direct data support comes from the fact that the basic specifications of the three engines are actually quite similar. Based on 2.0T, all three engines have a standard bore of 83mm and a stroke of 92mm per cylinder.

From the perspective of high efficiency, this bore-to-stroke ratio has increased but is not particularly long. The addition of turbocharging has led Mercedes-Benz to abandon the retro high-revving design with a 1:1 bore-to-stroke ratio. However, even compared to the BMW B48 engine, which also covers 48V mild-hybrid and plug-in hybrid configurations, Mercedes-Benz's bore-to-stroke ratio of just over 1.1 can only be described as average. In simple terms, until the M254 engine, Mercedes-Benz still intends to use the internal combustion engine as the main drive, with electrification merely serving to enhance efficiency or assist performance to some extent, but it cannot rival the internal combustion engine in terms of driving status.

However, under the pressure of emissions and costs, the space for internal combustion engines to continue providing positive performance output is shrinking. On the other hand, electric motors can achieve remarkable results with minimal effort. Mercedes-Benz, which is deploying PHEV (plug-in hybrid electric vehicles), is well aware of this. Therefore, some models have begun to incorporate the Miller cycle. This is undoubtedly a friendly signal for plug-in hybrid models that need to consider scenarios where the internal combustion engine generates electricity. However, the current engine's stroke is limited, so there is not much potential to expand the compression ratio. The fundamental solution, of course, is to change the parameters of the individual cylinder and adjust towards the direction of a range extender. However, considering the costs of remolding, the performance considerations for 48V mild-hybrid models, and the 2-3 years of research and development time, its feasibility is not high.

The remaining option is to tap into the potential at this stage. This involves optimizing the logic of systems such as intake and exhaust, fuel injection, and ignition to achieve compatibility with 48V mild-hybrid and plug-in hybrid requirements within a single engine. More directly, it means being able to accommodate a deeper Miller cycle. Due to the diversity of assembly models, it is necessary to consider an electronically controlled continuously variable system similar to BMW's Volvetronic for valve adjustment. The high-pressure direct injection pressure and swirl design of the engine must be recalibrated due to the pressure of pre-ignition. Electrification and refinement of some hardware systems, coupled with software system adaptation, are operational approaches that may be more in line with Mercedes-Benz's development timeline, budget, and return on investment expectations.

High-Power Motors and 9AT Transmissions Can Coexist

However, if we follow the previous reasoning and do not narrow down the internal combustion engine component, another problem seems difficult to solve. This is because whether aiming for a more efficient fuel power system or a more powerful plug-in hybrid system, a larger motor is required. Therefore, the fundamental question is where to find the space for a larger motor.

Currently, automakers such as Mercedes-Benz and BMW that adopt the P2 hybrid powertrain architecture generally use an integrated design combining the transmission and motor. The original intention was that such an operation would have minimal impact on the spatial structure of the original model. However, the integrated design and the working nature of the P2 single motor have always posed significant challenges to its stability. In summary, based on this structure, further increasing the motor size is almost impossible.

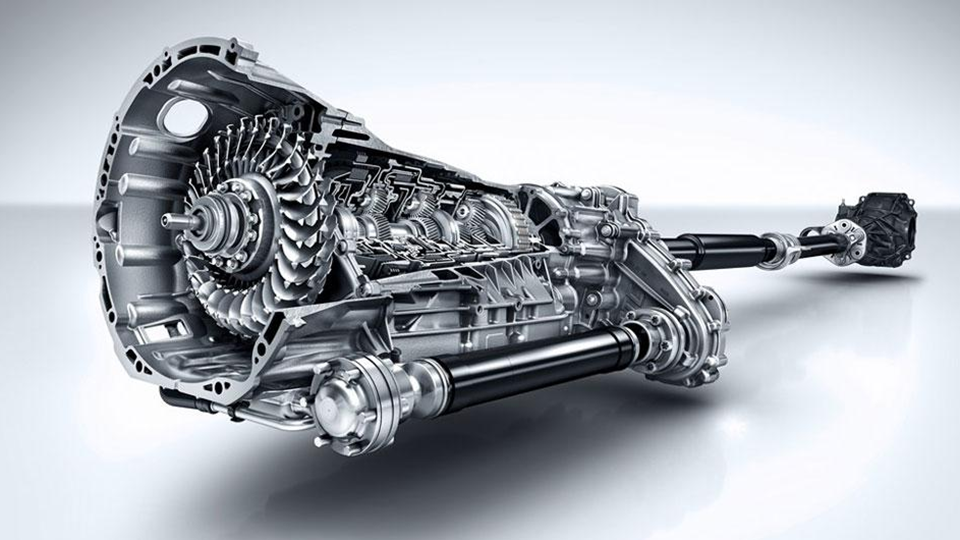

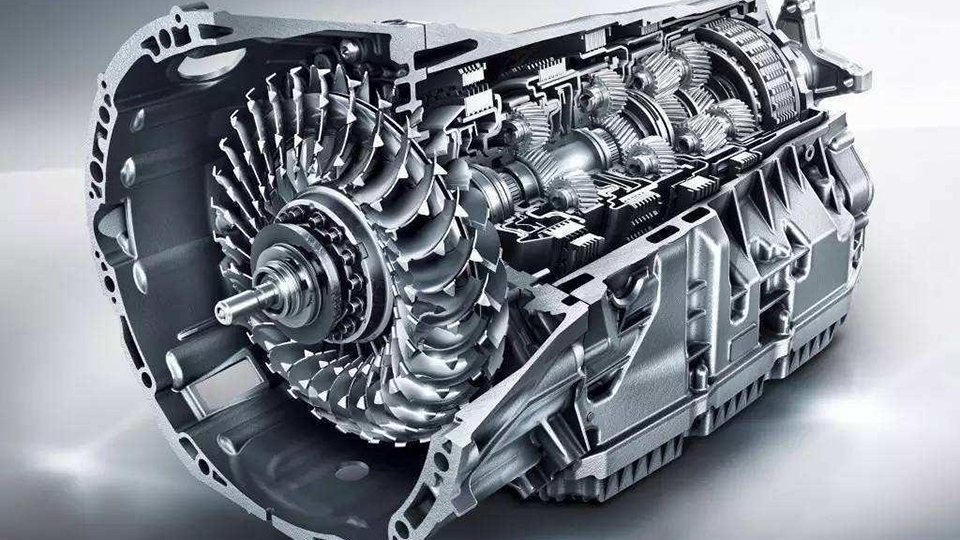

The radical solution would be to separate the P2 motor independently. However, faced with Mercedes-Benz's engines, which are predominantly in-line configurations, especially the in-line six-cylinder engines of the Mercedes-Benz S-Class, which is explicitly mentioned for an upgrade of its internal combustion engine system, there is clearly no space to separate the P2 motor. Therefore, the space is likely to be found within the transmission. The most extreme approach would be to eliminate the low-speed gears. After all, with a large motor, the necessity of low-speed gears is not strong. However, as mentioned earlier, such an operation cannot accommodate the needs of mild-hybrids and plug-in hybrids. At the same time, the development difficulty and cost are too high. Excluding the complex planetary gearshift structure, omitting the torque converter at the front end of the transmission almost becomes the only explanation for this issue.

From a technological trend perspective, players like BMW, Toyota, and Mazda, who have entered the P2 architecture, have all made significant efforts to address the torque converter issue. In fact, Mercedes-Benz has also undertaken similar operations. The current 9AT transmission, compared to Mercedes-Benz's previous 7AT transmission, has reduced power loss from around 15% to approximately 8% by targeting the torque converter alone. Specifically, this is achieved by directly locking the torque converter in low-speed gears. Mazda took note and praised the expertise. However, unlike Mazda, which needs to compensate for the jerkiness of low-gear switching through high rpm, Mercedes-Benz, with motor intervention, can avoid this through proper calibration.

So, if the space for the torque converter is completely omitted and a direct insertion approach is adopted, not only will efficiency be improved, but more space can be freed up for the motor section. In fact, Mercedes-Benz has already adopted a similar approach in some AMG models, replacing the original torque converter with a clutch structure. AMG models lead the way, oriented towards performance. Deploying this approach on the Mercedes-Benz S-Class, which requires both performance and maturity, also aligns with technological development logic.

In summary, Mercedes-Benz's new internal combustion engine powertrain is likely to be based on the current M254 (M256) engine series. Through partial hardware upgrades and software calibration, it will be better suited to plug-in hybrid models that need to consider power generation efficiency. The power of the P2 motor is bound to increase, and when paired with a more efficient internal combustion engine, the fuel consumption of the original gasoline-powered models should be further reduced. For plug-in hybrid models, it is possible to use a motor with relatively higher horsepower compared to the gasoline version. This approach is reminiscent of the 2026 F1 regulations, where internal combustion engine drive and electric motors have achieved a 1:1 ratio. However, in the civilian vehicle category, the motor cannot be completely separated from the transmission. But a larger battery pack is sufficient to support the performance logic.