Revolutionizing Quality Management with AI's "Three Technical Axes": Greatech Intelligence Empowers the Quality Ecosystem

![]() 07/04 2025

07/04 2025

![]() 758

758

On July 4th, at the Quality Management Seminar organized by the China Quality Club, Zhao Zhi, General Manager of the QMS Product Division at Greatech Intelligence, delivered a keynote address titled "AI Empowers Quality Management." His presentation systematically elucidated how industrial AI can transcend the core challenges of traditional quality management. Addressing the AI-driven transformation in quality management, Zhao Zhi introduced a three-phase implementation roadmap of "Data Governance × Model Development × System Autonomy" alongside empirical cases of AI-based quality prediction and management. This provided over a hundred technology leaders in the quality ecosystem with a practical approach to implementing AI+Quality Management.

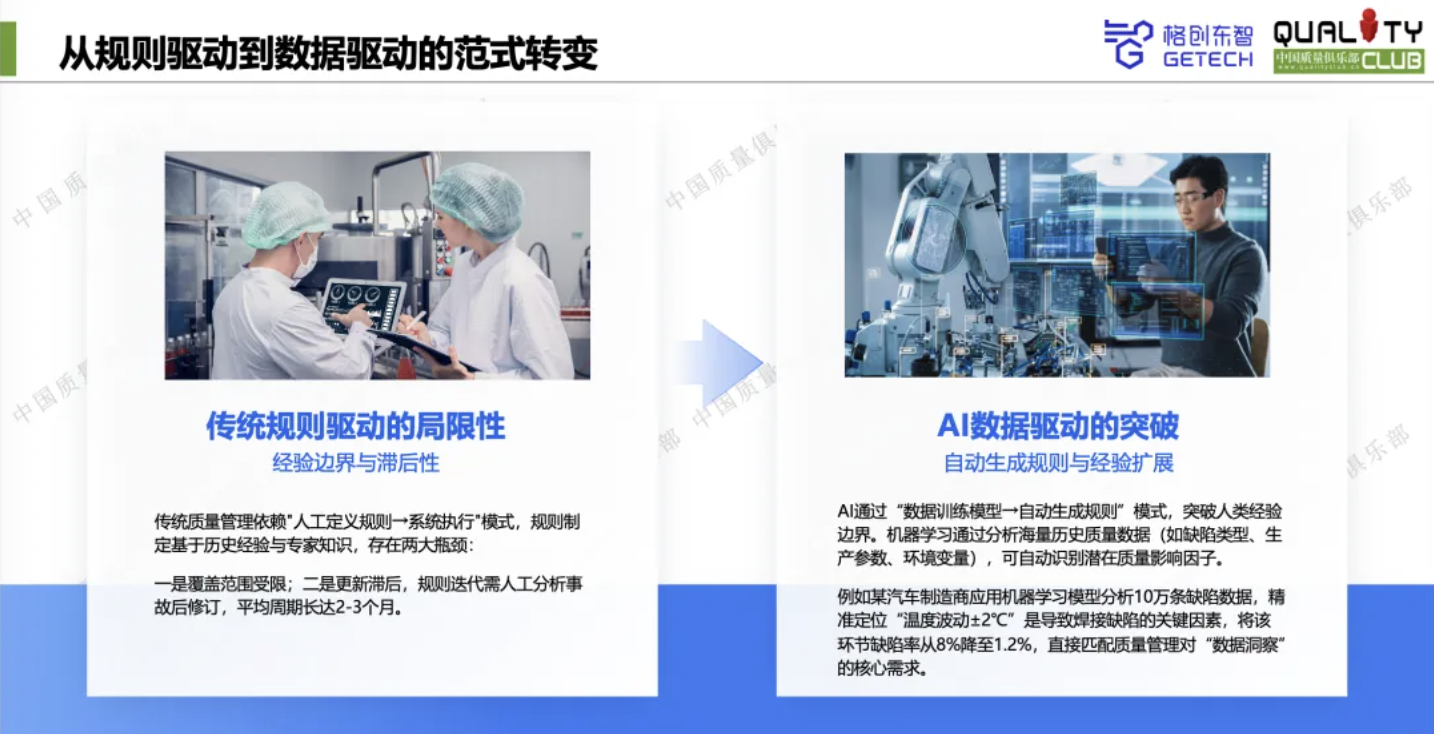

Currently, quality management in the manufacturing industry is hindered by issues such as heavy reliance on manual labor, fragmented data, and outdated rules. Zhao Zhi highlighted that the traditional quality management model, transitioning from "manually defining rules" to "system execution," has limited coverage and lags in updates. In contrast, AI can transcend human limitations by "training models with data" to "automatically generate rules." AI machine learning analyzes vast historical quality data (encompassing defect types, production parameters, and environmental variables) to autonomously identify potential quality influencing factors. For instance, an automobile manufacturer utilized a machine learning model to pinpoint temperature fluctuations of ±2°C as the key factor causing welding defects, reducing the defect rate in this process from 8% to 1.2%. This directly addresses the core demand of quality management for "data insights." Consequently, Zhao Zhi advocated for a paradigm shift in quality management, transitioning from rule-driven to AI data-driven.

In this shift, Zhao Zhi unveiled Greatech Intelligence's "Three Technical Axes" methodology for the first time: Firstly, establish a comprehensive quality data foundation spanning the entire product lifecycle, integrating multi-dimensional data sources like equipment parameters, environmental variables, and material batches, thereby enhancing the utilization rate of effective data. Secondly, introduce an intelligent inspection system that leverages transfer learning technology to create high-precision models, improving inspection accuracy. Finally, construct a "Quality Brain" for root cause tracing, utilizing knowledge graph technology to correlate factors across the entire supply chain, including raw materials, equipment, and processes. This reduces the time to identify root causes to minutes through AI correlation analysis. Zhao Zhi cited an example of a quality management project addressing battery swelling in a specific batch. Leveraging the "Quality Brain" system, the customer swiftly identified the combined causes of "abnormal electrolyte + offset injection pressure + overtime operation," markedly enhancing troubleshooting efficiency.

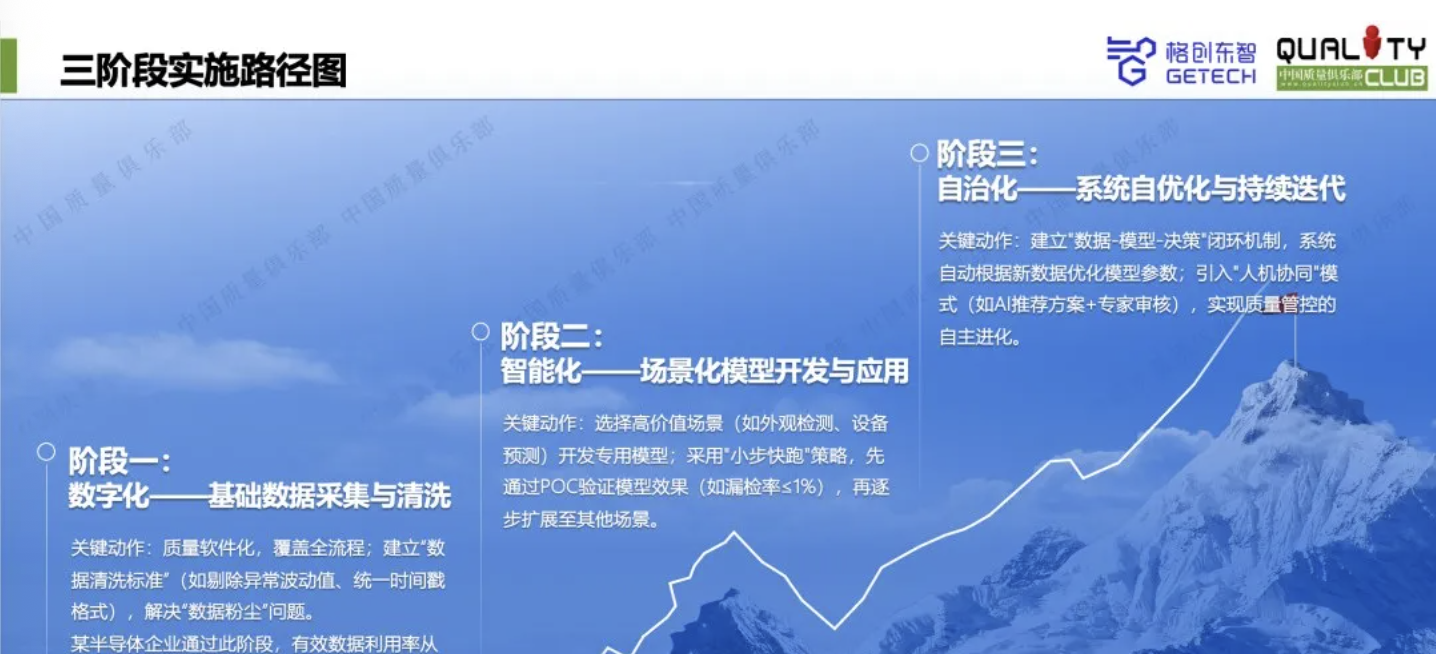

Regarding the implementation path, Zhao Zhi shared Greatech Intelligence's three-phase roadmap for refining the AI+Quality Management solution: digitization, intelligence, and autonomy. The first phase involves addressing scattered data issues through quality software and data cleaning standards. The second phase entails selecting high-value scenarios (such as appearance inspection and equipment prediction) to develop dedicated models, gradually expanding using the "small steps, fast iterations" POC strategy. Finally, Greatech Intelligence has established a closed-loop mechanism of "data + model + decision-making" to achieve autonomous quality control.

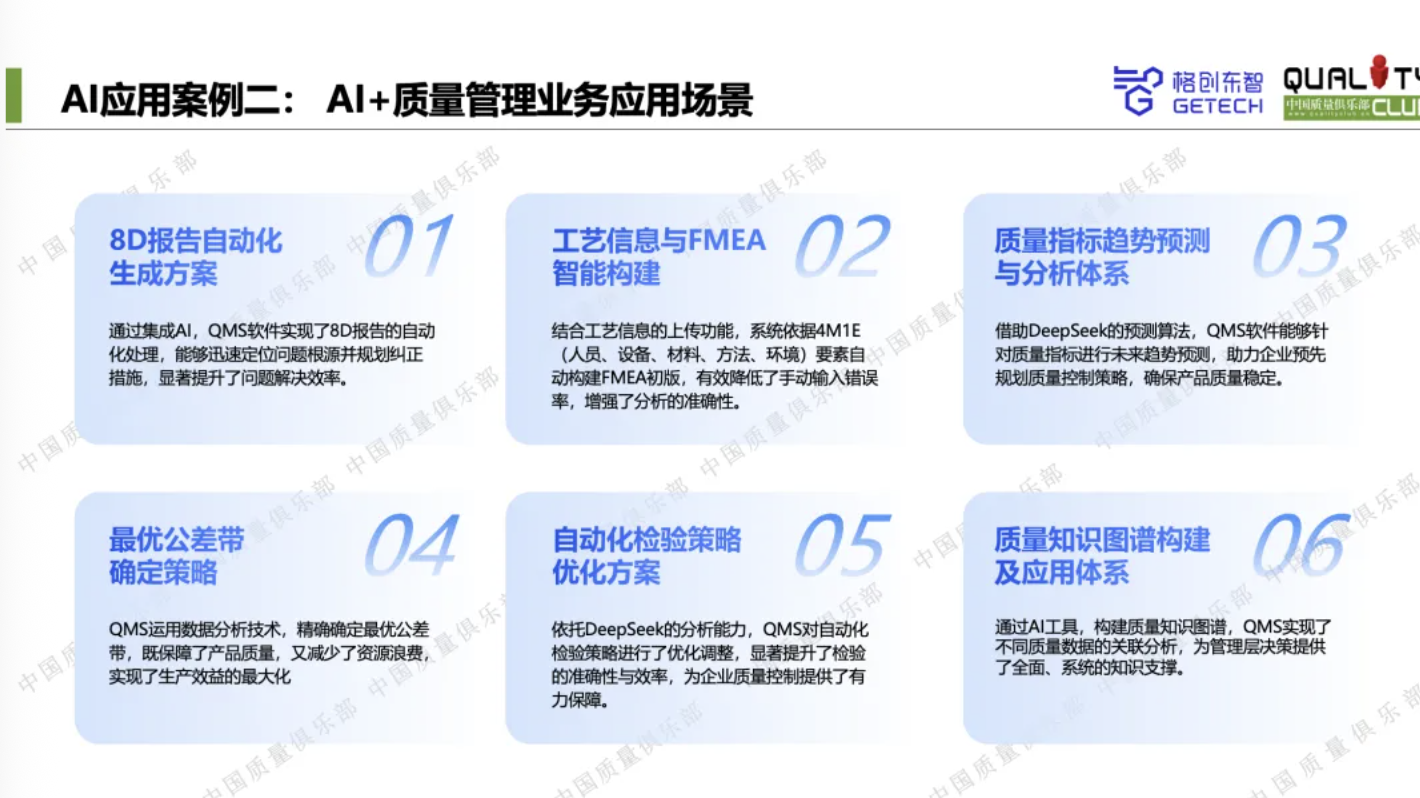

Taking the quality prediction scenario as an example, based on real-time process parameter data and measurement data, Greatech Intelligence has developed an AI+Big Data mining quality prediction model. This model, without interrupting the production process, can capture the dynamics of process quality in real-time, detect potential quality risks in advance, and adjust production strategies promptly, thereby enhancing product quality and reducing waste rates. Additionally, the company has developed a comprehensive suite of AI+Quality Management tools, including automated 8D report generation solutions, intelligent construction of process information and FMEA, quality indicator trend prediction and analysis systems, and automated inspection strategy optimization solutions. Notably, in the practice of a leading domestic robot vacuum cleaner enterprise, the AI-generated 8D report for after-sales issues has transformed the quality department from a labor-intensive center to a profit center, generating nearly ten million yuan in hidden annual revenue for a single plant.

Greatech Intelligence has consistently led the way in industrial AI research, development, and trials. Leveraging over 40 years of industry expertise from TCL Group, the company has reconstructed a fully integrated, independently controllable system, developed its own AI large model platform, and deeply integrated advanced and intelligent AI tools into multiple business scenarios, including manufacturing execution, equipment automation, quality management, energy and carbon management, logistics automation, and digital supply chains. This positions Greatech Intelligence as a leader in technical strength, industry recognition, and customer satisfaction.

At this seminar, Greatech Intelligence's sharing provided participants with a comprehensive understanding of the closed-loop implementation of AI in quality management, from strategy formulation to algorithm training. As a pioneer in industrial AI, Greatech Intelligence will continue to explore new horizons for AI+Quality Management, supporting more advanced manufacturing clients in their journey towards high-quality growth.