Are Humanoid Robots Held Back by 'Dexterous Hands'?

![]() 11/10 2025

11/10 2025

![]() 431

431

Produced by Zhineng Technology

Musk once boldly claimed that Tesla's humanoid robot, Optimus, would emerge as the "most significant product in history." However, it appears that the project has hit a temporary roadblock, and the stumbling block is a single "hand."

The dexterous hand serves as a vital link between robot intelligence and the physical realm, and it has evolved into the most formidable technological hurdle that the global robotics industry must surmount.

Tesla's decision to postpone finalizing the Optimus 3.0 suggests that the challenges associated with dexterous hands may be prompting a more cautious approach to humanoid robot development. This is due to the significant balancing act required between engineering feasibility and commercial viability.

01

When 'Hands' Become Bottlenecks: The Tesla Case

The delayed development of the third-generation Optimus robot serves as a stark reminder that the challenges facing humanoid robots extend far beyond algorithms and data. Numerous engineering obstacles persist.

According to supply chain information, Optimus's dexterous hand has already determined its technological path but continues to grapple with several challenges, including heat dissipation, durability, and cost. Each hand costs up to $6,000 and has a lifespan of only six weeks. In industrial settings, the annual maintenance costs alone can approach $100,000.

The fundamental challenge in the dexterous hand industry lies in reconciling complexity with reliability.

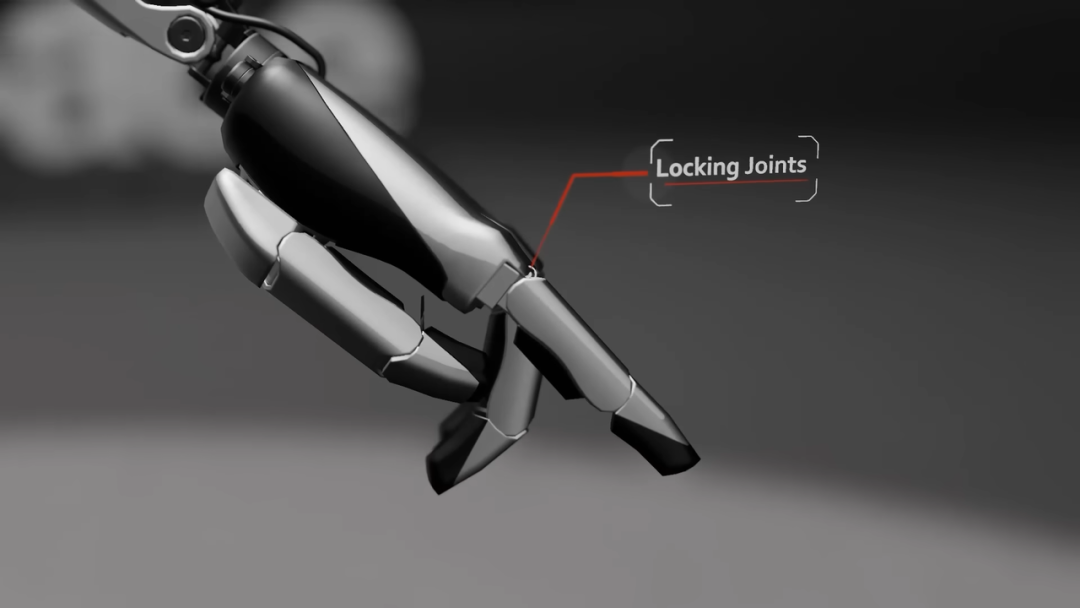

The dexterous hand is the most critical interactive organ for humanoid robots. The human hand, with its 27 bones, 29 joints, and 34 muscles, is capable of performing thousands of distinct actions. Replicating this level of flexibility in a mechanical structure necessitates the integration of motors, lead screws, gears, tendon ropes, and sensors within a confined space of several hundred cubic centimeters.

Tesla's approach involved increasing the number of actuators from 17 to 22 in the second-generation model and incorporating electronic skin sensors in the palm area to enhance flexibility and perception. However, this increased complexity has led to a cascade of interconnected issues, including heat dissipation, control challenges, and fatigue life concerns.

During testing, Optimus's dexterous hand frequently malfunctioned during tasks such as sorting express deliveries. The tendon ropes driving the fingers aged and snapped, while the flexible electronic skin rapidly wore out upon contact with objects, necessitating frequent component replacements.

Engineers even sought assistance from surgeons to study the muscle exertion mechanisms of the human hand, in hopes of finding a design balance that combines strength and flexibility. However, this issue remains unresolved to this day.

From a broader industry perspective, Tesla's predicament is not unique. The high complexity and short lifespan of dexterous hands are nearly universal challenges faced by global peers.

Whether it's Figure AI in the United States or domestic companies like UBTECH, Fourier Intelligence, and BrainCo, all are exploring similar transmission and perception solutions but consistently struggle to balance flexibility and durability. The average lifespan of dexterous hands currently ranges from 1,000 to 2,000 hours, which is far below the standards for industrial-grade robots.

Nevertheless, dexterous hands remain an indispensable pathway for humanoid robots to achieve commercialization. They determine not only whether the robots can function but also the range of tasks they can perform. Without sufficiently flexible and reliable hands, humanoid robots will remain confined to demonstrations and laboratories, unable to truly enter factories, warehouses, or even households.

02

Divergence and Convergence of Technological Routes: The Future of Dexterous Hands

At the 2025 International Conference on Intelligent Robots and Systems, dexterous hands emerged as the absolute focal point. From upstream transmission manufacturers to downstream complete machine manufacturers, over half of the exhibition booths showcased their dexterous hand products. The commercialization window for dexterous hands is approaching, but the technological routes remain diverse and ununified.

The transmission mechanisms of dexterous hands primarily fall into three categories: direct drive (linkage or gear), tendon drive (tendon rope), and hybrid solutions.

Each route reflects engineers' different attempts to strike a balance between "rigidity" and "flexibility."

◎ The direct drive scheme primarily utilizes linkages or gears, offering advantages in structural simplicity, precise control, and high reliability. For instance, WUJI's WUJI Hand, which employs linkage drive, features 20 fully active degrees of freedom and weighs only 600 grams, nearly equivalent to a human hand. This scheme is rigid, with controllable manufacturing costs, making it suitable for high-frequency repetitive operations in industrial scenarios. However, its flexibility is limited, making it difficult to achieve delicate movements akin to those of a human hand.

◎ The tendon rope drive route mimics the human finger's tendon system, placing the power source (motor) in the arm or wrist and using thin tendons to transmit tension and drive the fingers. This design is lightweight and soft, maximizing the replication of human hand dexterity. Sharpa's dexterous hand, SharpaWave, employs a 22-degree-of-freedom tendon rope transmission and integrates dynamic tactile array sensors (DTA) at the fingertips, enabling it to identify minute sliding and pressure changes for precise grip control. Sharpa's dexterous hand can perform high-precision operations such as "drawing cards" and "passing objects," demonstrating a nearly human-like sense of control. However, the tendon rope scheme also has significant drawbacks, including high maintenance costs, limited control precision, and a short lifespan.

◎ An increasing number of manufacturers are opting for "hybrid solutions." Companies like Tesla and Figure AI are exploring routes that combine direct drive and tendon drive: rigid gears or linkages are used for key joints to enhance stability, while tendon rope transmissions are employed for finger sections to increase flexibility. This "rigid-flexible" design aims to strike a compromise between flexibility, stability, and cost. However, it entails higher engineering complexity and stringent requirements for mechanical layout and algorithmic coordination.

From a technological trend perspective, the evolution direction of dexterous hands is gradually becoming clear:

◎ First is miniaturization and high integration. By utilizing high-density actuators, integrated sensors, and flexible circuits, the degrees of freedom and control precision per unit volume can be enhanced.

◎ Second is multi-modal perception fusion. Beyond vision, the integration of force, tactile, and temperature perception will endow dexterous hands with higher adaptive capabilities.

◎ Third is material innovation and novel drives. From flexible electronic skin to liquid metal and artificial muscles, material technologies are bringing new possibilities to dexterous hands.

For Tesla, it is imperative to transform dexterous hands from "showpieces" into "industrial components." Only when the cost drops to the thousand-dollar range, the lifespan reaches tens of thousands of hours, and maintenance methods are standardized can dexterous hands support Optimus's vision of millions of units. Achieving this goal may still require several years of engineering iterations.

Summary

The research and development of dexterous hands involve enabling machines to mimic human hand movements and endowing them with the ability to interact with the world. It also reflects the depth of robots' understanding of the physical world—how to exert force, perceive, and correct errors. We may need to continue observing for a while to see how this field evolves.