Silicon Carbide Semiconductors - The Next Key Technology for Electric Vehicles and Photovoltaic Inverters

![]() 07/22 2024

07/22 2024

![]() 465

465

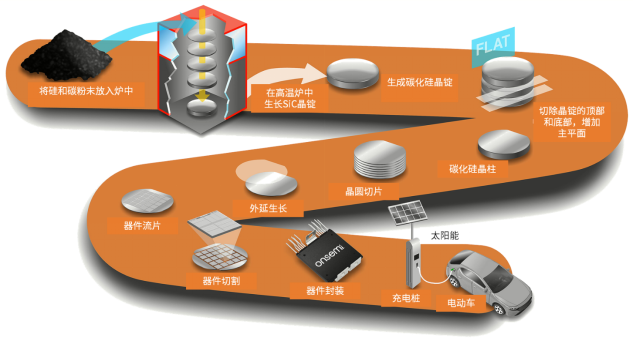

Figure 1: Semiconductors are crucial for many emerging green technologies

There is no denying that from a societal development perspective, we must transition to sustainable alternatives. The intensifying climate anomalies and shrinking polar ice caps clearly demonstrate the escalating impacts of climate change. However, the unfortunate truth is that moving away from fossil fuels is proving extremely difficult, and the shift towards green technologies brings with it a host of technical challenges. Whether it's ramping up production to keep pace with rapidly expanding markets or striving for new solutions to match the output levels of existing systems, these hurdles must be overcome if we are to leave fossil fuels behind.

For applications like electric vehicles (EVs) and solar panels, engineers face even greater challenges as sensitive electronic components must operate reliably in harsh environments. To further advance these sustainable solutions, we need innovations at the component level that help improve the efficiency of the entire system while offering greater robustness. Silicon Carbide (SiC) semiconductors, as a technology capable of delivering these necessary advancements, are rapidly coming into focus.

What are Silicon Carbide Semiconductors?

As part of the third-generation semiconductor technology, SiC solutions exhibit wide bandgap (WBG) properties, offering superior levels of performance. Compared to previous generations, the larger bandgap between the top of the valence band and the bottom of the conduction band increases the energy required for the semiconductor to switch from insulating to conducting. In contrast, first- and second-generation semiconductors require energy values between 0.6 eV and 1.5 eV for this transition, while third-generation semiconductors require values between 2.3 eV and 3.3 eV. In terms of performance, WBG semiconductors boast ten times higher breakdown voltages and are less thermally activated. This translates to higher stability, enhanced reliability, better efficiency through reduced power loss, and higher temperature limits.

For EV and inverter manufacturers requiring exceptional high-power, high-temperature, and high-frequency performance, SiC semiconductors represent an exciting prospect. But how exactly does this performance manifest, and how is the semiconductor industry preparing to meet the potential demand?

SiC for Electric Vehicles

In electric vehicles and their supporting charging networks, high-performance semiconductors are at the heart of AC-DC charging stations, DC-DC fast charging piles, motor inverter systems, and automotive high-voltage DC-to-low-voltage DC converters. SiC semiconductors strive to optimize these systems, offering higher efficiency, higher performance limits, and faster switching speeds, thereby shortening charging times and making better use of battery capacity. This can increase EV range or reduce battery size, lightening vehicle weight and lowering production costs while enhancing performance and fostering wider adoption.

Although EVs operate at lower temperatures than their internal combustion engine counterparts, they still pose a demanding environment for power electronics, with thermal management a critical factor for designers. For many early silicon and insulated-gate bipolar transistor (IGBT) devices, operating conditions within EVs could lead to failures within the vehicle's lifetime. SiC solutions have significantly higher thermal limits and an average three times higher thermal conductivity, making it easier to dissipate heat into the surrounding environment. This improves reliability, reduces cooling requirements, further lightens weight, and eliminates packaging concerns.

The increased peak voltage ratings and surge capabilities offered by SiC technology also support manufacturers aiming to shorten charging times and reduce vehicle weight. Typically, most EV infrastructure operates within a voltage range of 200 V to 450 V, but automakers are pushing performance further by increasing this range to 800 V. The first to make this shift was the premium Porsche Taycan, but an increasing number of manufacturers are following suit, with Hyundai recently launching the Ioniq 5, which now features 800 V charging at a significantly lower retail price.

But what lies behind this shift? 800 V systems offer multiple advantages, such as faster charging times, reduced cable sizes (due to lower currents), and decreased conduction losses, all contributing to cost savings and performance enhancements. Currently, fast-charging systems rely on expensive water-cooled cables, which can be eliminated, while within the vehicle, smaller cables significantly lighten weight and increase range. For some manufacturers, boosting voltage to 800 V is necessary to achieve the performance gains required to convince consumers to adopt EVs, but this development is only possible with SiC semiconductors. Existing second-generation semiconductors simply don't have the performance and reliability required to operate at such high voltages in the harsh environments of EVs and their charging infrastructure.

SiC for Sustainable Power Generation

Beyond EVs, the performance of this new generation of SiC semiconductors will also benefit numerous growing industries. Renewable energy is expanding rapidly, so solar/wind farm inverters and distributed energy storage solutions (ESS) relying on semiconductor technology are projected to experience rapid growth with CAGRs of 13% and 17%, respectively. (Source: Global Solar Central Inverter Market Report 2022-2026)

Similar to increasing vehicle voltages in the EV industry, SiC technology enables solar farms to increase string voltages. Existing installations typically operate at 1000 V to 1100 V, but new central inverters using SiC semiconductors can operate up to 1500 V. This reduces string cable sizes (due to lower currents) and the number of inverters required. As each device can support more solar panels, a significant hardware expense in solar farms, reducing inverter counts and cable sizes can notably decrease overall project costs.

The benefits of SiC technology for renewable energy applications extend beyond supporting higher voltages. For instance, onsemi's 1200 V EliteSiC M3S MOSFET can reduce power losses by up to 20% in hard-switching applications like photovoltaic inverters compared to industry-leading competitors. When considering operational scale (with 208.9 GW of solar farms in Europe alone), such savings have a considerable impact. (Source: Global Centralized Photovoltaic Inverter Market Report 2022-2026)

In terms of reliability, solar farms and offshore wind turbines pose extremely challenging environments for electrical components, where SiC technology once again surpasses existing solutions. By supporting higher temperatures, voltages, and power densities, engineers can design systems that are more reliable, smaller, and lighter than existing silicon solutions. Inverter housings can be downsized, and many surrounding electronic and thermal management components can be eliminated. And with SiC enabling higher-frequency operation, smaller magnets can be used, further reducing system costs, weight, and size.

Challenges in Semiconductor Production

It's clear that SiC semiconductors represent an advancement in almost every aspect for EVs and sustainable energy generation. Using well-designed SiC MOSFETs and diodes can enhance the operational efficiency of entire systems while reducing design considerations and, in many cases, lowering overall project costs. However, as with any pioneering technology, significant demand will arise. One question many electronic engineers face is whether SiC manufacturing is ready for widespread adoption and whether production will remain reliable as volumes increase.

Fundamentally, one of the primary issues facing SiC is its manufacturing process. While abundant in space, SiC is rare on Earth. As such, it needs to be synthesized from silica sand and carbon in graphite furnaces at temperatures ranging from 1600°C to 2500°C. This process yields SiC crystal boules, which then undergo further processing to ultimately become SiC semiconductors. Each production step requires extremely rigorous quality control to ensure the final product meets stringent testing standards. To guarantee quality, onsemi employs a unique approach. As the only end-to-end SiC manufacturer in the industry, they control every production step from substrate to final module (Figure 2).

Figure 2: onsemi's End-to-End SiC Production

In their factories, silicon and carbon are combined in furnaces, then machined into cylindrical disks by computer numerical control machines and sliced into thin wafers. Depending on the desired breakdown voltage, specific epitaxial wafer layers are grown before the wafers are diced into individual dies and packaged (Figure 3). By controlling the entire process from start to finish, onsemi has been able to create a highly efficient production system prepared for the growing demand for SiC.

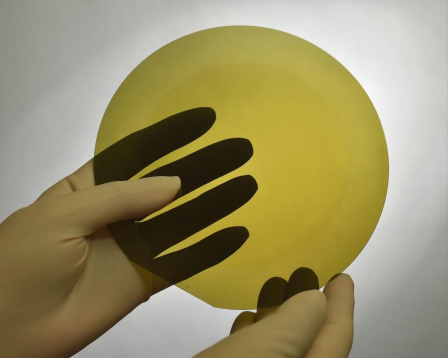

Figure 3: SiC Epitaxial Wafer Layers

While onsemi leverages its experience gained from silicon-based technology production, ensuring the high quality and robustness of the final product poses unique challenges for SiC materials. For instance, producing reliable end products requires surpassing many aspects of existing industry standards designed for silicon technology. Through extensive collaboration with universities and research centers, onsemi has been able to determine SiC's characteristics and reliability under various conditions. The result is a comprehensive, integrated approach applied across all onsemi's SiC production processes.

SiC - The Right Technology at the Right Time?

For sustainable technologies to make the necessary impact in the real world and help us achieve global climate goals, energy efficiency, reliability, and cost-effectiveness are crucial factors. Finding component-level solutions that satisfy all three objectives was nearly impossible in the past, but for many applications, this is precisely what SiC technology offers. While global supply shortages have somewhat delayed the widespread adoption of SiC semiconductors, it's clear that we are now poised to see rapid advancements in this technology.

Large-scale adoption of SiC will still face challenges, such as semiconductor manufacturers keeping pace with demand and ensuring reliability. But through collaboration and research, such as that conducted by onsemi, the industry should be able to maintain high standards and optimize manufacturing efficiency. In terms of deployment, it's important to remember that first- and second-generation semiconductors still have their place. For applications like logic ICs and RF chips, SiC's high performance may not be applicable, but for EVs and solar energy, SiC technology will prove transformative.