Greatech Eastwise Human-Machine Collaboration: Lean End-Side, Rewriting the “New Paradigm” of Flexible Production

![]() 10/29 2024

10/29 2024

![]() 551

551

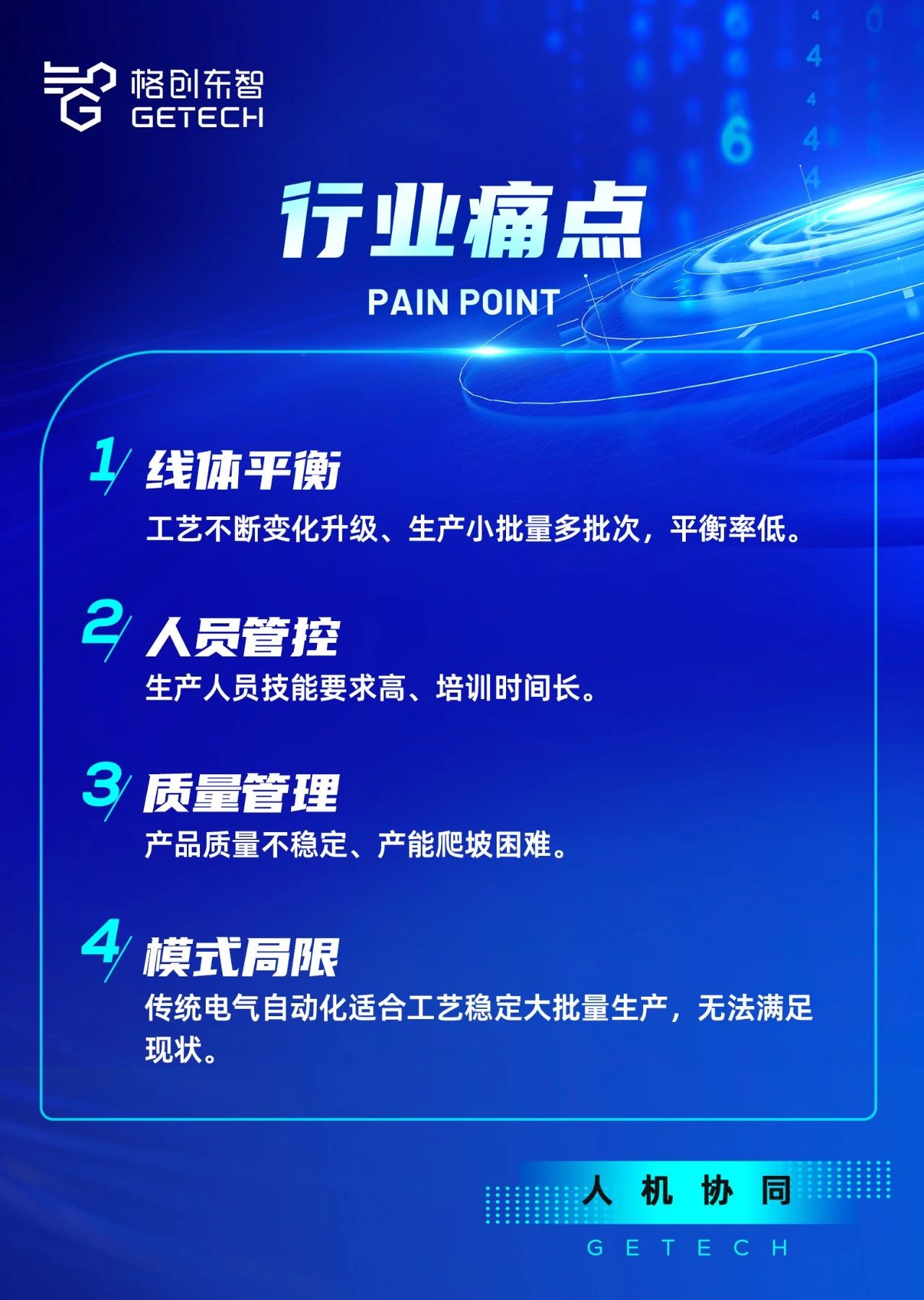

In the field of discrete manufacturing, especially in the equipment industry, the industry needs to address the challenges of highly customized flexible production lines, achieve intelligent production scheduling and resilient adjustment of process data, thereby improving production efficiency and flexibility. However, the flexibility and efficiency demonstrated by traditional workers in highly flexible production processes often fail to meet the high standards of modern production environments.

As a result, the new human-machine collaboration model is gradually entering the public eye, opening up a new path for the next generation of change.

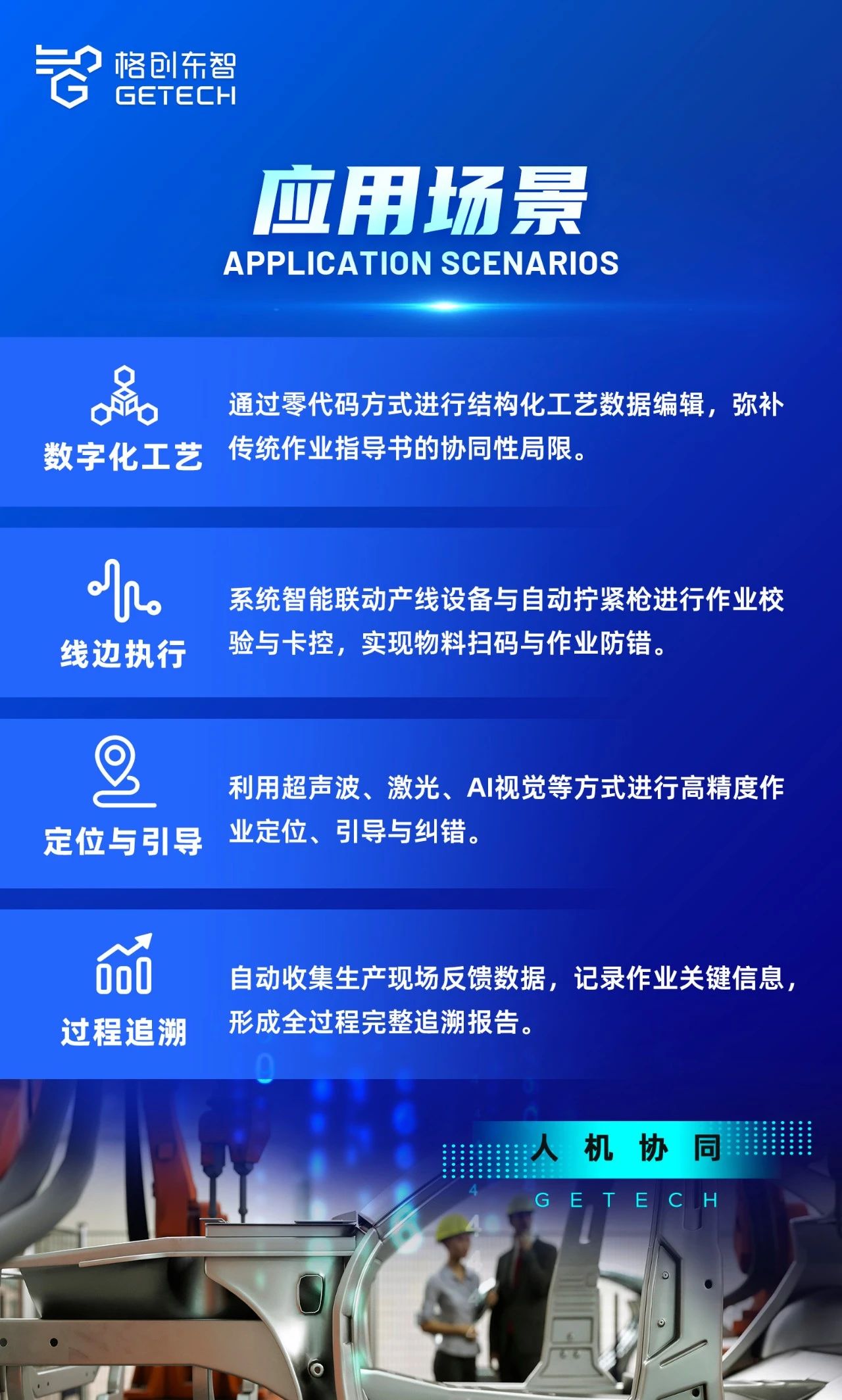

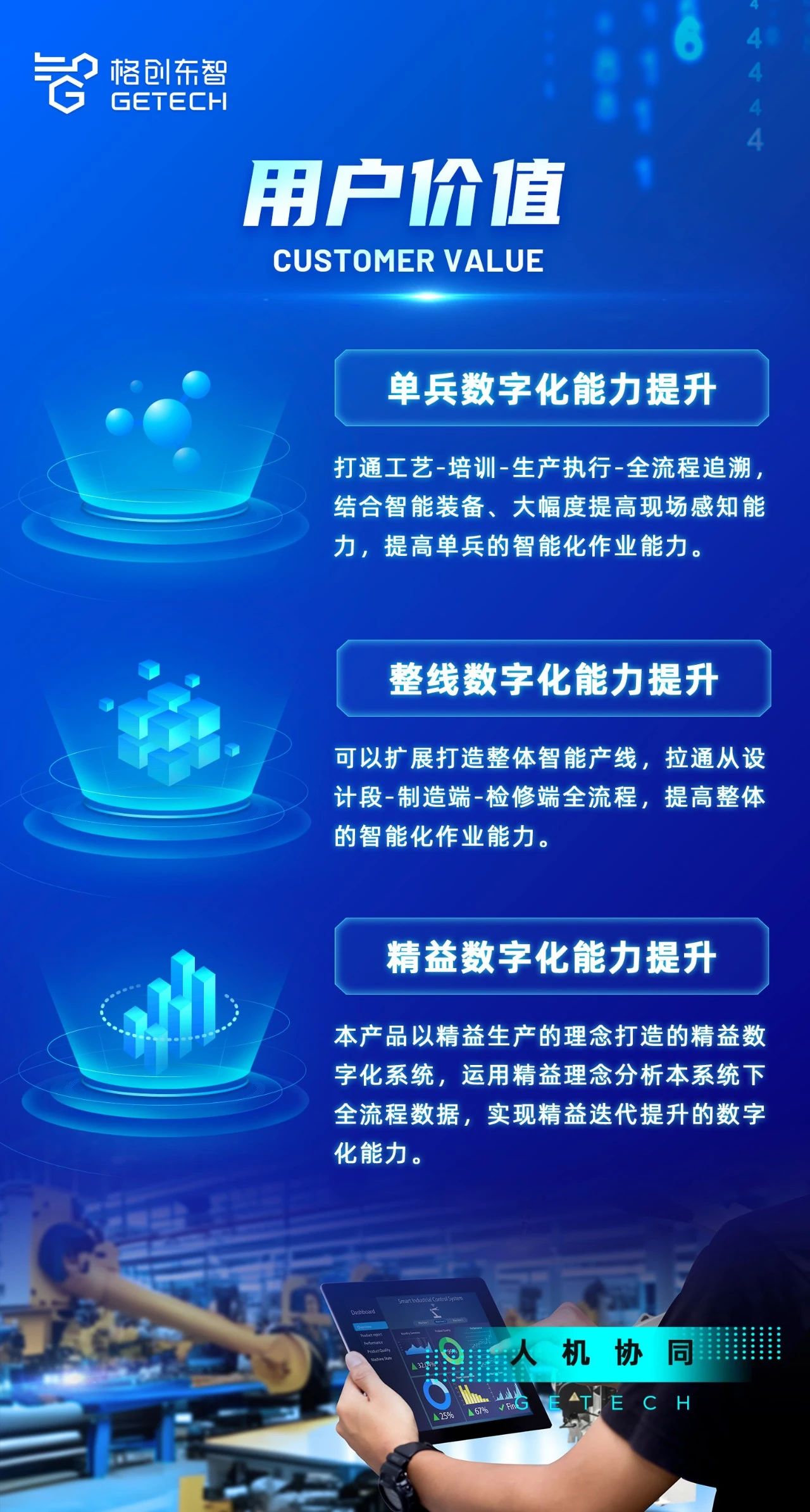

Human-machine collaboration involves using structured data as a basis for process guidance in complex environments, rationally scheduling workstation workloads and line-side resources, effectively integrating human, machine, material, method, and environment, bridging the consistency of perception, cognition, and action, enabling parallel control of multiple people and machines, and efficiently solving complex problems through an intelligent system. In discrete manufacturing, especially in the equipment manufacturing industry, it not only saves labor but also improves production accuracy and moderation, driving increased production capacity.

Greatech Eastwise's human-machine collaboration solution was born out of necessity,

aimed at the execution control scenarios of manual workstations on the assembly line in the equipment industry,

enabling a new experience in collaborative management such as industrial configuration, line-side execution, and process traceability.

IDC, an internationally renowned consulting firm, points out that the market size of human-machine collaboration systems will reach tens of billions of dollars in the future. With the rapid development of technologies such as artificial intelligence, big data, and cloud computing, human-machine collaboration technology will play an increasingly important role in discrete manufacturing in the future, exploring various collaboration technologies such as interaction, complementarity, and hybridity.

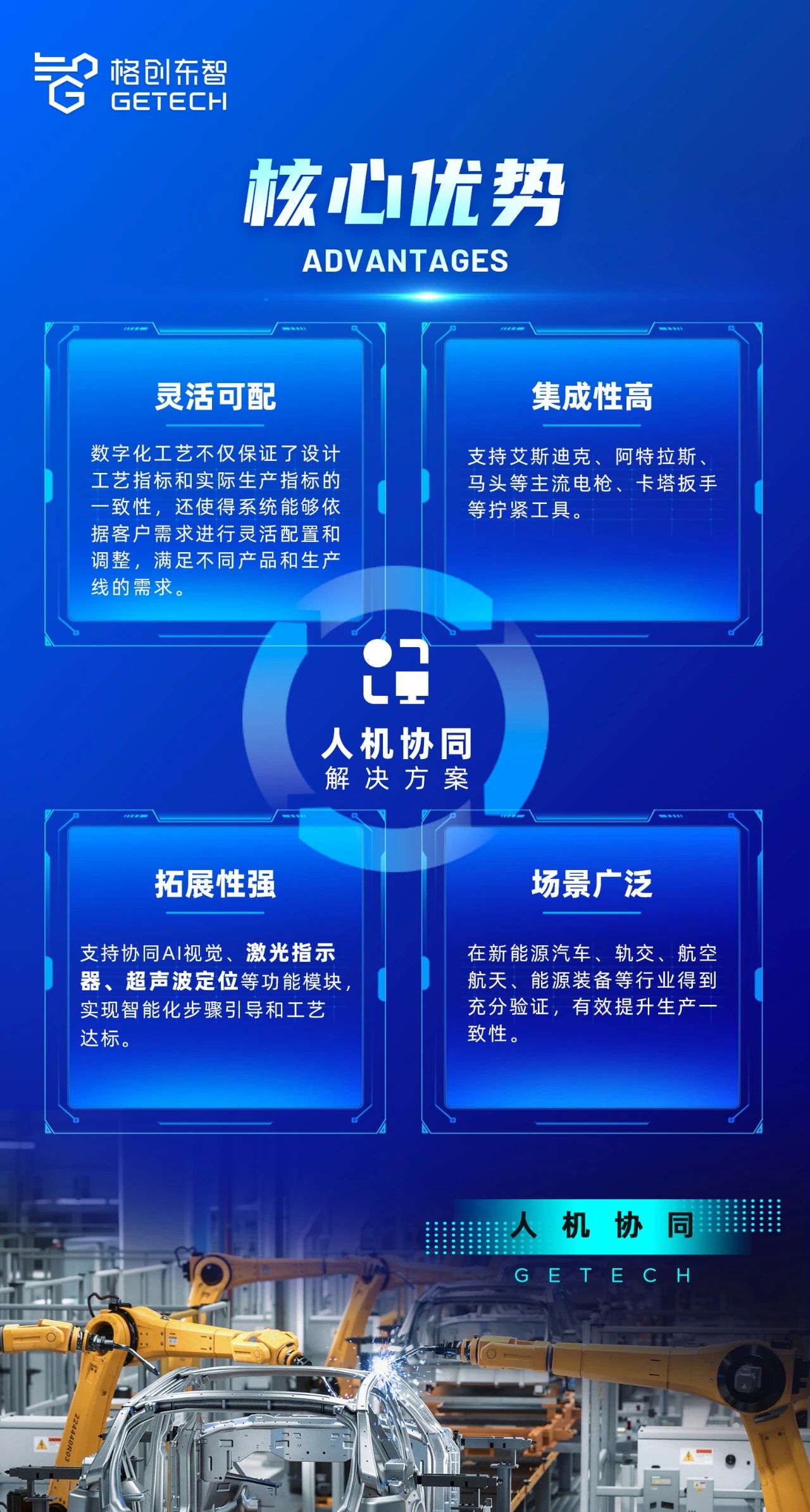

Greatech Eastwise's human-machine collaboration solution adapts to change,

is compatible with multiple industrial system invocation capabilities,

connects production resources across the entire site through structured data,

creating an “intelligent brain” for intelligent scheduling, production scheduling, and production optimization in factories,

boosting the “big score” in flexible production in discrete manufacturing.

Greatech Eastwise's human-machine collaboration solution solidifies value creation,

born out of a focus on the needs of flexible production in complex discrete manufacturing,

with advanced agile configuration to enhance production resilience.

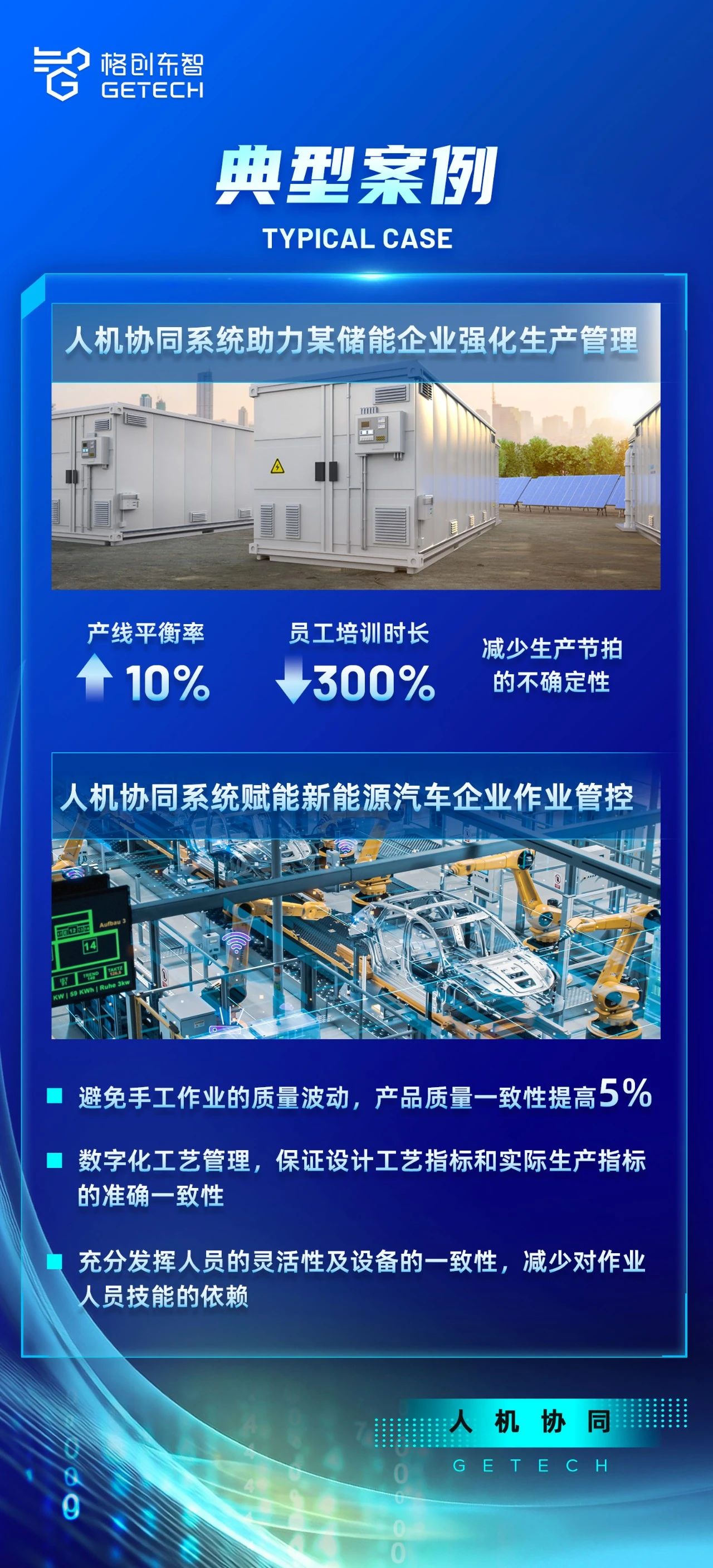

Greatech Eastwise's human-machine collaboration solution leads the market,

preferred in the equipment industry and trusted by assembly customers,

leading a new journey of human-machine scenario transformation.