GCL Dongzhi attends MT Digital Ecosystem Conference, unlocking the unlimited potential of 'Industry + AI'

![]() 11/08 2024

11/08 2024

![]() 506

506

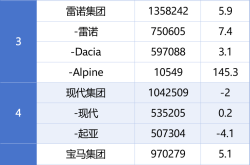

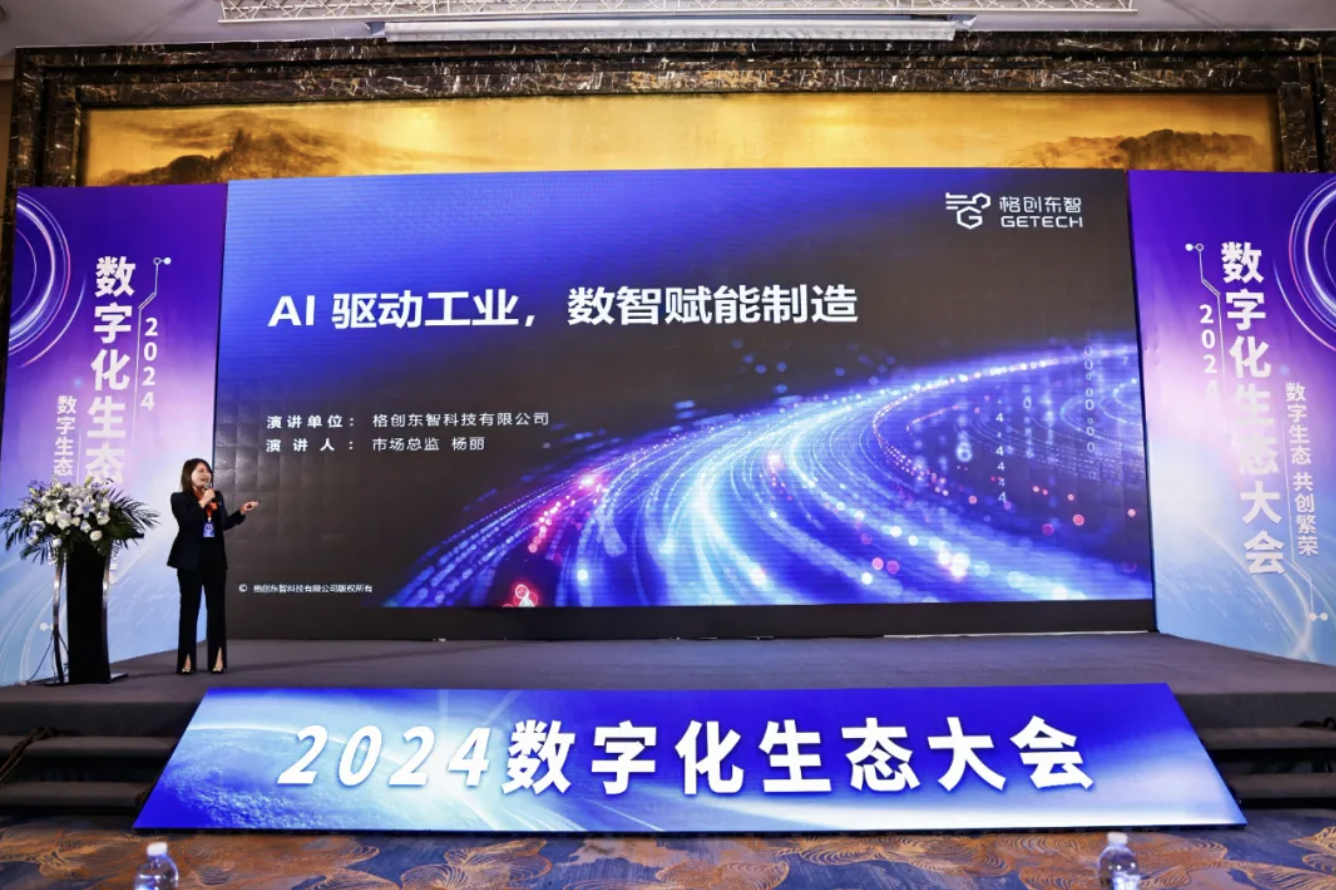

Today, as the wave of digitization sweeps across the globe, AI technology is accelerating its breakthroughs and deeply integrating into various industries, empowering Chinese enterprises to enter the "deep waters" of quality improvement and efficiency enhancement. As a leading enterprise in China's industrial AI, GCL Dongzhi, along with top leaders from more than 200 leading domestic and foreign companies such as Siemens China, Honeywell, ABB Robotics, and Supcon, attended the 2024 Digital Ecosystem Conference hosted by METTLER TOLEDO in Changzhou on November 6 to explore new paths and opportunities for digital transformation. At the conference, Yang Li, Marketing Director of GCL Dongzhi, was invited to attend and participate in the keynote speech and roundtable discussion, systematically elaborating on GCL Dongzhi's cognition and practice regarding AI implementation scenarios and development trends in the manufacturing industry during its exploration of AI technology, bringing new insights to participants.

In her keynote speech, Yang Li pointed out that in the field of industrial large models, thanks to their characteristics of precise parameterization, high professionalism, and strong implementation capabilities, industry-specific large models will unleash greater potential in industry. After deeply integrating with industrial big data and industrial software, they can provide timely and accurate suggestions for non-general issues and further guide the improvement of processes and procedures based on functions such as virtual experts, root cause analysis, and reverse control and optimization parameters, thereby improving production efficiency and product yield. Behind this, highly available and highly anthropomorphic pre-trained industrial large models will surpass the technological singularity, bringing disruptive changes to traditional manufacturing and infusing new vitality into intelligent manufacturing.

In fact, facing the golden opportunity period of AI, GCL Dongzhi's AI empowerment practice has surpassed the point-based empowerment stage and entered the stage of comprehensive intelligent application. In the TCL Huaxing smart factory empowerment practice, the AI business lines planned and implemented by GCL Dongzhi independently have covered multiple fields such as visual quality inspection, equipment health management, scheduling optimization, intelligent R&D and design, and continue to expand their application scenarios and value boundaries.

Furthermore, Yang Li shared AI empowerment practices across different industries. In the semiconductor industry, GCL Dongzhi helped a leading chip company accelerate the process of random inspection of film thickness using AI technology, significantly reducing the analysis time for different batches of film thickness and film formation anomalies, saving labor costs of 100,000 to 150,000 yuan per month. In the lithium battery field, GCL Dongzhi's AI algorithm can accurately identify abnormal factors in cell production and extract more than 50 key characteristic indicators through virtual measurement and root cause analysis, providing strong support for the accuracy of cell quality prediction and optimization. These successful cases fully demonstrate GCL Dongzhi's strength and innovation capability in the field of industrial AI.

Subsequently, during the roundtable discussion, GCL Dongzhi and leaders in the digital field from industry, academia, and research conducted in-depth dialogues on AI practices. Yang Li believes that the exploration of industrial AI business ultimately needs to return to practical purposes and needs. By analyzing the complexity of scenarios, the effectiveness of demand satisfaction, scenario data, and comprehensive dimensions such as AI-related technologies and ROI, the possibility of AI business implementation can be judged. Additionally, from a technology research and development perspective, a long-term mindset is required before diving into AI business, coupled with an open and sharing attitude and leveraging one's technological advantages to act in accordance with the trend. Furthermore, representatives from industry, academia, and research also shared their experiences and lessons learned in AI investment, providing participants with new perspectives and practical insights.

Great minds think alike, and together they create wisdom. At this conference, we witnessed in-depth and broad ideological collisions among leading forces from industry, academia, research, and application. We also observed the leading practices and innovative achievements of front-runners in the fields of digitization and industrial AI. The conference brought together the capability boundaries and advanced practices of enterprises from different fields to support the development of China's digital economy and new industrialization, maximizing the advantages of empowerment.

As the digital transformation of the manufacturing industry enters "deep waters" and AI technology continues to evolve, GCL Dongzhi believes that the future manufacturing industry will become smarter, more efficient, and more sustainable. GCL Dongzhi will continue to stand at the forefront of the industry and technology, leading and driving the development process of new industrialization and the sink of AI into the manufacturing industry.