"Partner + Huawei", the optimal solution for digital and intelligent transformation across all industries

![]() 12/10 2024

12/10 2024

![]() 636

636

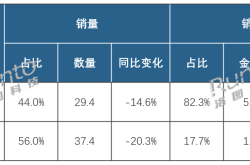

More than a month ago, the digital and intelligent factory of Changan Automobile was officially unveiled, impressing the outside world with a series of figures: the overall manufacturing efficiency of the factory increased by 20%, costs were reduced by 20%, energy consumption decreased by 19%, and on average, every 60 seconds, a new car rolls off the digital and intelligent factory line.

The results of digital and intelligent transformation are undeniably attractive, but in the understanding of many people, such a narrative seems to belong only to the leading enterprises in the industry.

Because the process of exploring digital and intelligent transformation is also a process of continuous trial and error, requiring continuous investment of a large amount of capital and manpower, and facing the risk of transformation failure or minimal effectiveness. As a result, when the digital and intelligent process of leading enterprises represented by Changan accelerates, many above-scale enterprises are still waiting and seeing.

In response, Qiu Heng, CMO of Huawei China's Government and Enterprise Business Group, gave a "standard" answer to the digital and intelligent transformation of various industries: For small, medium, large, and micro enterprises in China, as long as they choose the "Partner + Huawei" system, they can acquire a full set of capabilities, including independently innovative technology, in-depth scenario solutions, marketable and easy-to-use products, as well as thoughtful services and a local team, combined with Huawei's rich experience in digital and intelligent transformation and industry benchmark practices, enabling customers from all walks of life to "instantly access the digital world".

01

"Leave the complexity to us, bring simplicity to customers"

Behind helping manufacturing industry customers accelerate their digital and intelligent transformation and upgrading is first and foremost Huawei's ability spillover.

According to Yang Ping, General Manager of Huawei China's Government and Enterprise Business Group Intelligent Manufacturing System Department: Huawei is a company that originates from manufacturing and understands manufacturing better. In 2018, it comprehensively launched an artificial intelligence strategy, introducing large model technology into various business areas through the "R&D, production, supply, sales, service + AI + data" model.

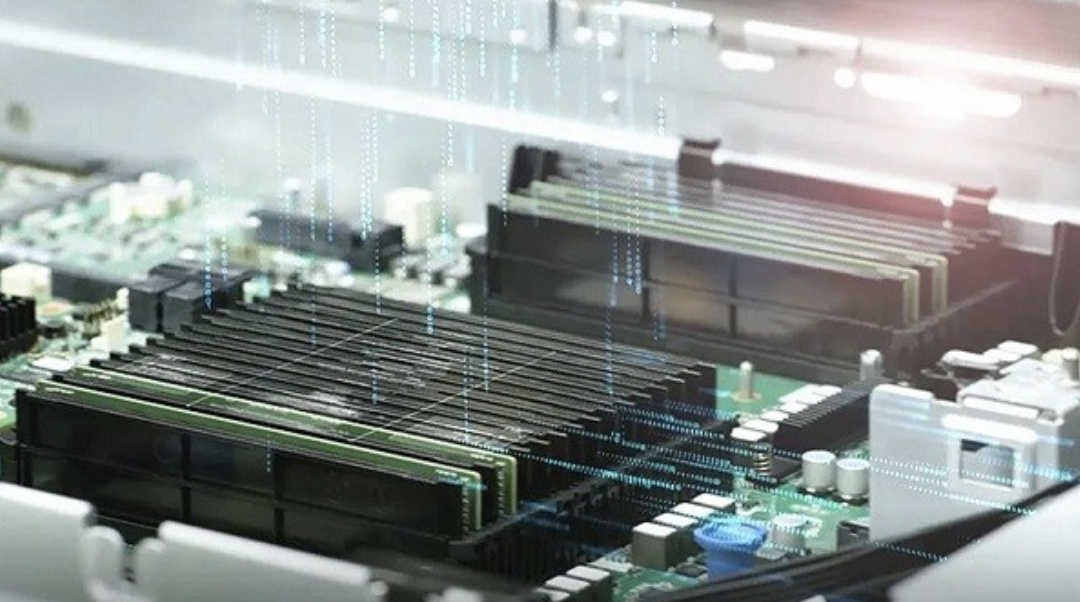

Taking production execution as an example, Huawei uses large model technology and data governance to clean and train data required throughout the entire process, including market order data, R&D code, warehousing and logistics data, and production line equipment data, greatly improving factory agility, efficiency, and productivity. The originally 80-person high-end mobile phone production line now only requires 14 people, and a mobile phone can be produced every 20 seconds.

In its cooperation with Changan Automobile's digital and intelligent factory, Huawei relies on its own digital and intelligent transformation experience to build a solid digital foundation for the factory, realizing the cloud-based collection of data from all factory hardware devices, helping to connect the three core business flows of the automotive manufacturing industry: engineering data flow, business information flow, and production process flow, providing a solid digital platform capability for business transformation and upgrading, continuous efficiency improvement, smart application innovation, and green sustainable development.

Not only Changan Automobile's digital and intelligent factory, but under the mission of "leaving the complexity to us and bringing simplicity to customers", Huawei has served more than 7,500 manufacturing enterprises nationwide, covering various industries such as automobiles, equipment manufacturing, electronics, household appliances, pharmaceuticals, heavy industry, tobacco, and new energy.

02

There is a set of methodology behind "digital and intelligent" transformation

The "troubles" of digital and intelligent transformation are not limited to the traditional automotive manufacturing field.

Qiu Heng, CMO of Huawei China's Government and Enterprise Business Group, specifically mentioned Xunqiang Electronics, a company in Huizhou, Guangdong, that serves thousands of global brands by producing electronic components. As the speed of digital and intelligent transformation accelerates, its business development is "hampered" by the park network. Network capacity, quality, and security have become "bottlenecks" for business development.

In the network upgrade construction of its Huizhou factory, Xunqiang Electronics chose Huawei's campus network solution to create a comprehensive and powerful wireless network based on Huawei's Wi-Fi 7 technology advantages. Compared to other Wi-Fi 7 products in the industry, Huawei's Wi-Fi 7 can first achieve a 3-fold increase in bandwidth performance, efficiently supporting 1G high-definition video downloads in seconds and stable operation of industrial production networks; in addition, paired with Huawei's 2.5GE multi-rate POE++ switch, it can efficiently increase data transmission rates, enhance power supply capabilities, and ensure stable operation of network equipment.

Secondly, it possesses exclusive fusion scheduling technology that can achieve fusion scheduling in airspace, frequency domain, time domain, and applications. At the same time, Huawei's APs use intelligent coordination and packet-by-packet customized transmit power to achieve a 4-fold increase in concurrent performance, supporting 120 terminals to simultaneously enjoy 1080P high-definition video without lag.

Thirdly, it creates VIP user protection. Through exclusive "superframe" technology dedicated slicing, it ensures VIP users enjoy an exclusive lane, and through packet-by-packet power control to enhance VIP signals, it creates a user experience with zero damage, improving satisfaction by 100%.

Finally, in terms of security, in response to the challenges of hackers being able to use WLAN air interface information to capture packets and obtain communication data for data cracking, Huawei Wi-Fi 7 uses exclusive Wi-Fi Secret Shield technology so that illegal users can only capture useless noise packets and cannot obtain users' real business packets, thereby avoiding hackers listening to and cracking data and information through Wi-Fi data, successfully safeguarding network security, and jointly building Xunqiang Electronics' intelligent connectivity foundation.

As a globally leading ICT infrastructure provider, it is reported that Huawei has more than 600,000 terminals for daily office use, more than 20,000 video conferences per day, and the transmission of 2.8 million emails... It has also encountered challenges in the park network, accumulating long-term experience in fusion scheduling, secret shield technology, elastic slicing, and other aspects, and productizing Wi-Fi 7 technology to completely solve the bottleneck of the network experience.

The question is, how can Huawei's technologies, solutions, and other capabilities efficiently "spill over" to all walks of life, enabling customers from various industries to accelerate their digital and intelligent transformation? Qiu Heng's answer is: "After serving so many customers, we have found that different industries are like mountains apart, but the principles are the same. To this end, we have summarized a set of universal transformation practice methods."

In summary, this set of digital and intelligent transformation practice methods are: architecture first, platform first, scenario innovation, and iterative advancement.

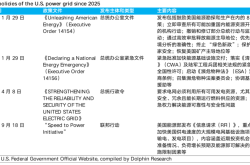

Regarding architecture first and platform first, based on years of successful practice, Huawei has also proposed a reference architecture for industry intelligent agents. Any industry that wants to build an intelligent architecture must first solve five-level problems: including using 5G, F5G, cameras, sensors, and other technologies to achieve intelligent perception and intelligent connectivity; then building an intelligent foundation based on Huawei Cloud, computing, storage, etc., providing capabilities such as general computing, AI computing, and data lake ingestion; modeling data through data governance, content development, model development, and other tools on the intelligent platform; and ultimately using innovative applications one by one to help customers create tangible value.

Qiu Heng also emphasized that this practice method is not a closed architecture but is jointly created by "Partner + Huawei". Huawei focuses on its proficient technologies and products, working with partners to deeply understand industry scenarios, accurately grasp customer needs, combine technology with business scenarios, combine IT and OT, and conduct scenario innovation and iterative advancement, thereby serving the entire lifecycle of customers' digital and intelligent transformation.

03

The "Partner + Huawei" system is becoming stronger and stronger

Because the "Partner + Huawei" system itself is designed to better serve all walks of life.

"Partner + Huawei" is a system with complementary roles, strong capabilities, and wide coverage. Huawei excels in technological innovation and product development, while partners are closer to customers and have a deeper understanding of their needs. As long as customers find a partner nearby, they can find Huawei and obtain Huawei's capabilities and practical experience, realizing digitalization in a simpler and easier way.

As is well-known, the digital and intelligent transformation of an industry is not only a breakthrough and exploration from 0 to 1 for leading enterprises but more importantly, it is about achieving widespread replication from 1 to N. Rapidly replicating the digital and intelligent transformation experience and capabilities explored by benchmark enterprises through the "Partner + Huawei" system and ultimately helping enterprises of all sizes in the entire industry avoid detours is the key to promoting new productive forces and achieving high-quality development across the entire industry.

For example, AI quality inspection technology, which has been deeply applied in the traditional manufacturing field, is also applicable to the textile industry.

Take a company that produces lace fabrics as an example. Due to the delicate and complex yarn of lace fabrics, manual quality inspection is intensive, and it is difficult to ensure inspection efficiency and accuracy, leading to difficulties in recruitment, high costs, and low efficiency. To this end, Huawei collaborates with partners to introduce AI quality inspection technology into the textile industry.

Unlike manual quality inspection, AI quality inspection can inspect while weaving, with an average detection rate of over 95%. Moreover, once a problem is detected, it can be handled in real-time to avoid large quantities of defective products, not only improving inspection efficiency and reducing the possibility of defective products but also lowering costs.

It is understood that the current "Partner + Huawei" system already has more than 40,000 partners, covering key capabilities throughout the entire lifecycle of digitalization, including consulting, solution development, operation, and maintenance; among them, in 2024 alone, Huawei collaborated with more than 4,000 partners in the commercial market, serving more than 13,000 commercial market customers.

From an industry perspective, the robustness of the "Partner + Huawei" system can be seen as an inevitable outcome: the more benchmark cases of digital and intelligent transformation among leading enterprises, the more mature scenarios that can be replicated, and the wider range of customers that partners can serve... This continuous positive cycle drives more and more enterprises with digital and intelligent transformation demands to embrace the "Partner + Huawei" system, easily realizing digitalization.

04

Final Thoughts

Many people say that digital and intelligent transformation is a comprehensive, complex, and gradual long-term process.

To some extent, this view is not wrong. Digitalization cannot be achieved overnight, nor can all problems be solved with one solution, but this does not mean there is no "shortcut" for digital and intelligent transformation.

At least the "Partner + Huawei" system has already shown the outside world that with just one "touch", one can connect to independently innovative technologies, in-depth scenario solutions, marketable and easy-to-use products; obtain a local team and thoughtful services; and replicate the transformation practice experience of benchmark enterprises in the industry.

This will undoubtedly further stimulate the new productive forces of various industries and help them accelerate their high-quality development.