Big Models First, Small Models Next: Generative AI Testing the Waters in Industry - Breaking the Data and Reliability Deadlock

![]() 12/11 2024

12/11 2024

![]() 648

648

This is my 352nd column article.

In my previous article, "From Large Language Models (LLM) to Small Language Models (SLM) to TinyML, This Field is Expected to Grow 31 Times," I discussed the advancements in small models, SLMs, and now this field is quietly achieving breakthroughs.

Small models, SLMs, can be seen as a "mini version" of large models, LLMs. Despite their compact size, they possess formidable capabilities. Unlike LLMs like GPT-4, which have millions or billions of parameters, SLMs operate on a much simpler scale. Optimized SLMs can efficiently handle simpler tasks without consuming significant computational resources.

Today, small models are making great strides towards industrial application, no longer mere "toys" in the lab, but becoming a vital force across various industries.

Technology giants have already sensed the untapped potential of small models and have joined the fray for future dominance.

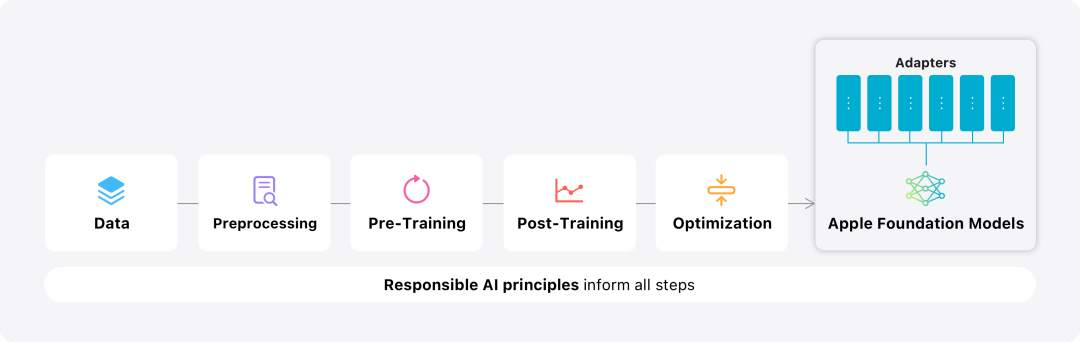

Companies such as Microsoft, Google, and Apple have all ventured into the small model SLM market, with notable examples including Microsoft's Phi-3, Google's Gemma, and Apple's Foundation Models.

Recently, Microsoft has launched a new AI small model specifically tailored for the industrial sector.

Through collaborations with companies such as Bayer, Rockwell Automation, and Siemens, these small models are pre-trained using industry-specific data and can address key issues. They serve as a customized set of "intelligent equipment" for each industry, enabling AI to penetrate every production link, enhancing efficiency, optimizing processes, and creating value.

In this article, we will delve into the latest progress of small models in industrial applications and understand the opportunities and challenges they present.

Small Models and AI Agents: The Next Big Thing?

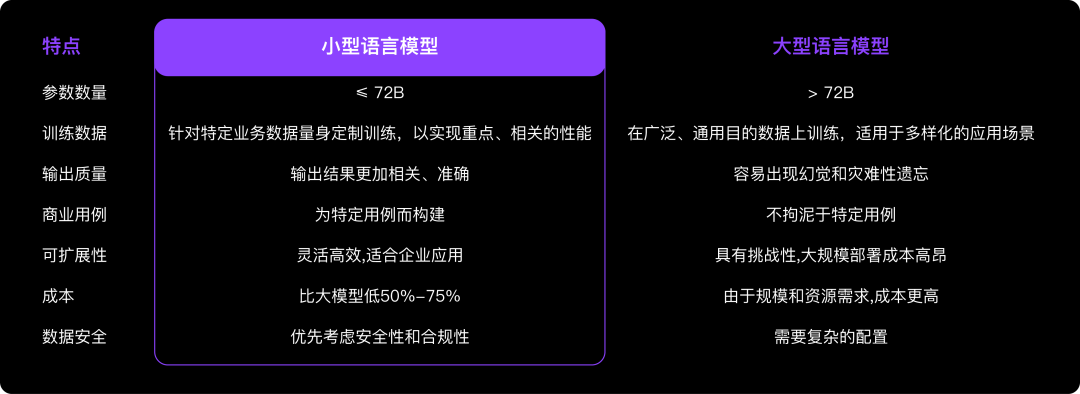

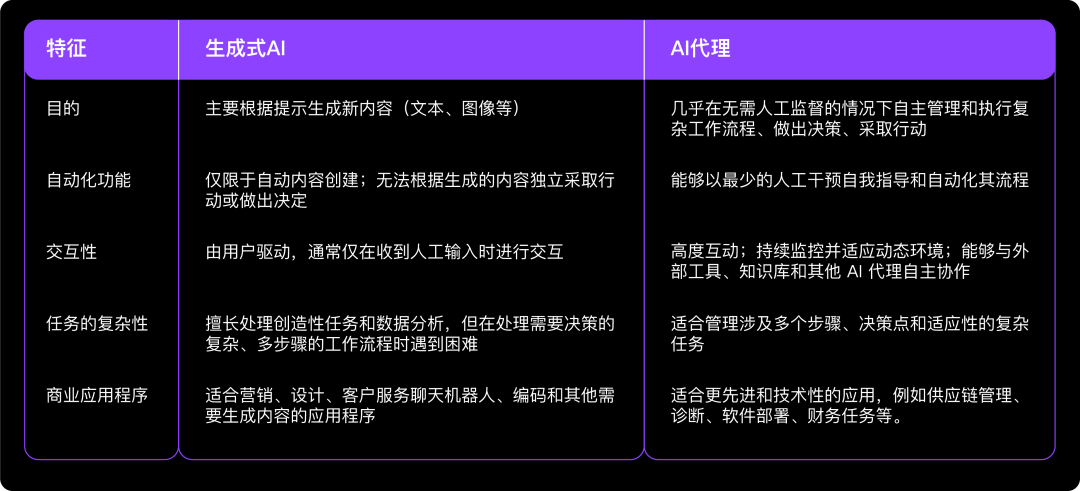

First, let's clarify the difference between large models and small models, as illustrated in the image above.

Small models are "small" not only because they have fewer parameters but also because they are often fine-tuned on smaller datasets to optimize their performance for specific tasks, making them more suitable for business workflows.

The strength of small models lies in handling specific tasks and workflows. Despite having a limited number of parameters, when fine-tuned with customized datasets for domain-specific tasks, small models can outperform large general models. Task-specific training can reduce hallucinations and enhance problem-solving abilities.

Resource efficiency is another standout feature of small language models, making them particularly attractive to enterprises looking to implement AI solutions across various platforms and devices. Small models allow enterprises to fully leverage the benefits of AI with simpler infrastructure and lower costs. It is estimated that small models can save up to 75% of model training costs and over 50% of total deployment costs.

Building on small models, we can also devise many innovative concepts.

Some companies utilize small models in AI agent workflows, where multiple small models communicate and collaborate to perform more complex tasks.

For instance, in an AI agent workflow, the first AI agent might plan how to solve a task, the second conducts necessary research, the third executes the plan, and the fourth validates and evaluates the results. This collaborative approach demonstrates how these models work together to increase productivity and achieve more complex outcomes.

Here, let me explain what an AI intelligent agent is.

An AI agent is officially defined as an intelligent entity that can perceive the environment, make decisions, and execute actions.

In simpler terms, ChatGPT is not an AI agent, but AlphaGo, which defeated Lee Sedol, can be considered an AI agent.

Currently, our interactions with AI typically involve inputting instructions, and the AI model responds based on those instructions. This means we need to provide effective prompts each time to achieve the desired results.

Unlike this, an AI agent is designed as an AI program with independent thinking and action capabilities. We only need to provide a goal, such as writing a game or developing a webpage, and the AI agent will autonomously generate a task sequence and commence work.

Let's delve deeper into AI agents through a few examples.

A basic AI agent is an automatic air conditioning control system in a home. It operates based on a simple "if-then" principle: if the temperature is below the set point, turn on the heating; if it's above, turn it off. This basic AI agent, though simple, plays a crucial role in daily life.

On the other hand, advanced AI agents, like DeepMind's AlphaGo, are artificial intelligence systems designed for the complex game of Go. AlphaGo demonstrated remarkable learning abilities and ultimately defeated world champion Go players. This milestone underscores the enormous potential of AI agents in handling complex tasks.

Just like Russian nesting dolls, multiple primary and advanced AI agents can establish a layered agent system.

A layered agent system is an AI system that decomposes complex tasks into simpler subtasks and organizes them in a hierarchical structure. This approach allows agents to manage different levels of abstraction, making it more efficient to handle complex problems.

A typical example of a layered agent system is Amazon Go's "Just Walk Out" technology, which operates with a clear hierarchy:

Top level: Overall store management and inventory tracking

Intermediate level: Customer tracking and behavior analysis

Lower level: Product recognition and interaction detection

Lowest level: Sensor data processing and fusion

Relying on the collaborative work of these AI agents, Amazon Go has garnered significant attention in the retail industry and tech circle with its innovative shopping experience of "just walk out without queuing."

The above cases are merely the tip of the iceberg, and the potential applications of AI agents are vast and untapped.

Small Models and Copilot Cover Over 100 Companies and 120,000 Users

After understanding the basics of small models and AI agents, let's explore the latest collaborations between Microsoft and industrial enterprises.

Companies experimenting with Microsoft's small models this time include Bayer, Rockwell Automation, Siemens, Sight Machine, and others.

Taking Rockwell Automation as an example, the company has started applying small models at the operational level. In the food and beverage version of the human-machine interface visualization platform FactoryTalk Optix, they use small models to bring industry-specific functionality to frontline manufacturing workers, supporting asset troubleshooting in the food and beverage sector. The AI model provides real-time advice, explanations, and knowledge to factory floor workers and engineers regarding specific manufacturing processes, machines, and inputs.

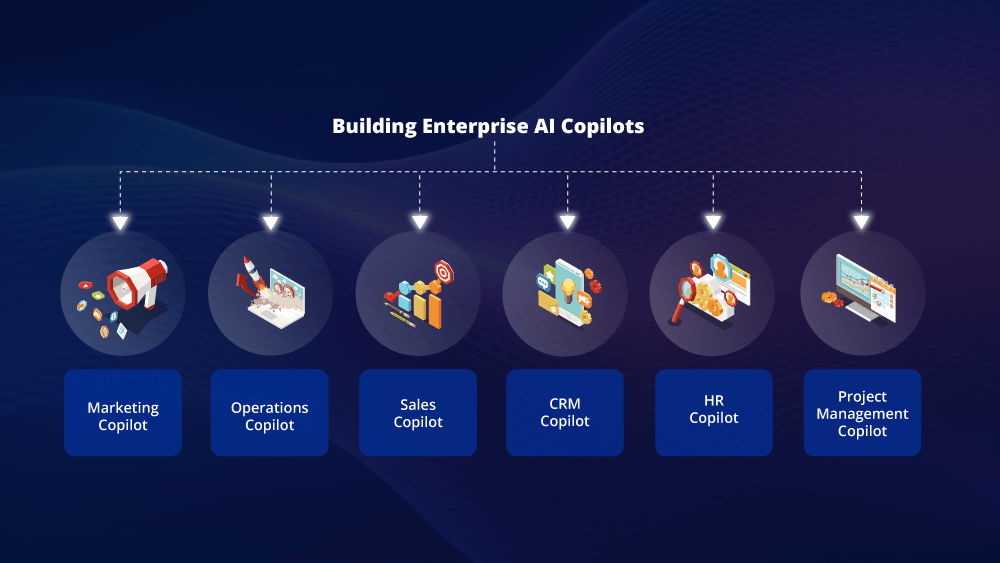

Another product, FactoryTalk Design Studio, is a cloud-native software focused on system design by Rockwell Automation. It uses Copilot to enhance PLC code creation and user management. Engineers can use natural language prompts to perform tasks such as product guidance, code generation, troubleshooting, and code explanation, making system design faster and more intuitive.

Similarly, Siemens is introducing a new Copilot for its CAD solution NX X software. This software utilizes fine-tuned AI models, enabling users to ask questions through natural language, obtain detailed technical insights, and simplify complex design tasks for faster and smarter product development.

Currently, over 100 companies, including Schaeffler and ThyssenKrupp Automation Engineering, are using Siemens Industrial Copilot to simplify processes, address labor shortages, and drive innovation. The 120,000 Siemens engineering software users now have the opportunity to enhance their productivity with the help of a generative AI-driven assistant.

As an early adopter, ThyssenKrupp Automation Engineering was the first company to use Copilot and plans to popularize its use within the company's global system starting from early 2025.

According to practical experience, engineers can now create visualization panels and generate code within 30 seconds, with only about 20% of the code requiring adjustments before direct application. This simplifies workflows, reduces manual workload, and addresses the shortage of skilled labor.

In specific scenarios, ThyssenKrupp uses AI to assist in the development of automation systems for producing automotive batteries. For example, in a battery quality inspection device, sensors, cameras, and measurement systems are integrated to monitor battery cell quality at multiple stages, conducting complex assessments to detect discharges exceeding set thresholds. Copilot enhances the operation of this equipment by automating multiple tasks such as data management, sensor configuration, and battery quality inspection, assisting operators.

Copilot: The Practical Role of Generative AI in Industry

In the industrial field, "thinking of it" and "doing it" are two entirely different matters, and the industrial value of generative AI still needs to be validated.

As the ancient saying goes, "To reap its benefits, first know its drawbacks." To fully leverage the advantages of small models, it is essential to understand their limitations.

The drawback of generative AI is its low reliability and lack of explainability, making it suitable only for scenarios with low reliability requirements.

The disadvantage of small models is their limited accuracy, inability to capture detailed features and relationships in large and complex datasets, and relatively weak predictive capabilities. Additionally, they struggle with complex problems. These drawbacks restrict small models to a supporting role, providing more feasible options for us to choose from, with the final decision still made by humans.

In practical applications, there are numerous challenges.

The biggest obstacle to the widespread adoption of AI in industry is the lack of data. Due to the multitude of factors involved in industry, including equipment, processes, operations, and the environment, it is difficult to obtain large amounts of multidimensional and comprehensive data. Although most manufacturers possess data, much of it is time-series data that has not been properly standardized and cannot be used for AI model training.

The essence of data issues often lies not purely in technology but in personnel and processes. Immature data management processes, the persistent gap between operational technology (OT) and information technology (IT), and a lack of understanding of small models are factors limiting generative AI to one-off pilots or experiments.

Therefore, generative AI currently exists more as a virtual assistant function in the industrial field and will continue to do so for an extended period.

These AI virtual assistants provide guidance to factory floor operators or help control engineers write PLC code. Given the current challenges of attracting and retaining factory floor talent, Copilot can easily assist in synthesizing real-time information or providing coding assistance.

In the past, engineers needed to be familiar with cloud platforms, sensors, the Internet of Things, artificial intelligence, and different types of time-series and engineering data. Generative AI allows engineers to easily perform data queries, visualizations, and workflows without worrying about complexity. Operators can ask questions on demand without needing to understand the software.

Many manufacturing enterprises are equipped with complex systems and more automated equipment, but senior employees with decades of experience and knowledge are gradually leaving the workforce. Manufacturers find it difficult to find young technicians to maintain existing systems. Copilot can be a tool to help bridge this gap.

For example, the AI assistant from industrial software company Aveva can help operators answer questions such as, "What was the maximum output in the workshop last month?" or "Why was this compressor less efficient this week?" DuPont has also started using generative AI to help engineers find information faster, saving hours of manual searching through manuals.

These Copilots act like expert consultants for operators, suggesting ways to improve output and reduce energy consumption as needed. In a sense, they are not fundamentally different from the original "expert systems," and whether to adopt these suggestions depends on the operators.

The challenges faced are similar to those of past "expert systems": how to establish trust in the consultants. New recipes often emerge in factories, and without proper updates and maintenance, expert systems can quickly become outdated. Another risk is how to check and validate all generative AI outputs. AI cannot say, "I don't know"; if there is no data, it may make something up.

Written at the End

In this era of interconnected devices and ubiquitous intelligence, small models and generative AI are revolutionizing the industrial field. From manufacturing floors to product design, operational optimization to fault diagnosis, AI is reshaping every aspect.

However, we must also clearly recognize that the path to AI application in the industrial field is not smooth. Challenges such as data scarcity, insufficient reliability, and limited explainability remind us to treat this emerging technology with caution. Nonetheless, we still have reason to be optimistic about the future.

As technological advancements continue and enterprises delve deeper into their practices, human-machine collaboration will only grow tighter, with small models and generative AI unleashing unprecedented potential in the industrial sector.

Reference materials: