Deep Ploughing in Manufacturing and Smart Manufacturing: Huawei's Collaborative Journey with Manufacturers

![]() 12/12 2024

12/12 2024

![]() 579

579

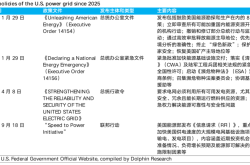

From the process management of IPD research and development to the oversight of the ISC supply chain, Huawei has progressively established IT information systems. To ensure the company maintains control as its business scales, Huawei embarked on its true digital transformation journey in 2014.

The manufacturing industry, the lifeblood of the national economy, stands as the backbone of the real economy and the core of the modern industrial system. With the continuous development and deep integration of AI, big data, cloud computing, and other cutting-edge technologies into manufacturing, embracing the 'new' and progressing towards 'intelligence' has become the sole path to achieving high-quality manufacturing development. So, how can traditional industrial enterprises implement their digital and intelligent strategic plans, and what novel opportunities will AI present for the advancement of the manufacturing industry and its digital and intelligent infrastructure?

Amid the wave of digital economy and intelligent manufacturing convergence, Huawei, as a manufacturing enterprise and ICT infrastructure provider with R&D at its core, continually strengthens itself while sharing its technological and managerial expertise. Through tailored solutions and consistent technical support, it aids the manufacturing industry in achieving digital and intelligent upgrades and fostering business innovation.

Deep Ploughing in Manufacturing and Smart Manufacturing

As a manufacturing enterprise with R&D as its core strength, Huawei's exploration and practice on the path to digital and intelligent transformation have not only yielded substantial business growth and efficiency gains for itself but also propelled the digital and intelligent evolution and development of the entire manufacturing sector. In 2014, Huawei initiated a comprehensive digital transformation, achieving granular management across production, supply, service, and other facets by establishing full-factor connectivity and a real-time feedback system. Building on this foundation, Huawei further incorporated AI technology and large-scale model services, deepening its digital and intelligent transformation.

Yang Ping, General Manager of Huawei China's Government and Enterprise Smart Manufacturing System Department

Huawei's IT development and business management evolution initially commenced in the 1990s, during the information construction phase. Yang Ping, the General Manager of Huawei China's Government and Enterprise Smart Manufacturing System Department, explained that from the process management of IPD research and development to the management of the ISC supply chain, Huawei progressively established IT information systems. To prevent the company from losing control as it expanded, Huawei embarked on its genuine digital transformation in 2014.

Firstly, the company forged a full-factor connectivity and real-time feedback system, fully integrating over 6 million pieces of equipment in the production field and facilitating seamless communication between dozens of devices from over a hundred brands, laying a robust foundation for subsequent production data interconnectivity across factories.

Secondly, Huawei implemented data governance, establishing a top-tier data governance structure, clarifying the specific responsibility scope for BOM data, and fostering data circulation among various departments to ensure effective communication based on a unified data set across different industries, groups, and functional departments.

Finally, Huawei constructed a robust security system. Data security is the cornerstone of digital transformation. To safeguard data, "we've implemented multiple protective measures, including host, network, application, and data firewalls, to thwart external threats and prevent unauthorized access, viewing, extraction, or modification, while ensuring internal recoverability," said Yang Ping.

In R&D, Huawei leverages AI technology to achieve full-process intelligence in code reading, writing, debugging, testing, and reviewing through AI development assistants, markedly enhancing coding efficiency. Furthermore, Huawei has established four major databases in R&D—an object library, rule library, process library, and model library—providing powerful data support and analytical tools for R&D personnel, further boosting R&D efficiency and innovation.

In production, Huawei's Smart Factory exemplifies the achievements of digital and intelligent transformation. By introducing advanced technologies like intelligent troubleshooting, logistics optimization, and production knowledge graphs, Huawei has achieved intelligent upgrading and efficient operation of production lines. Taking the Dongguan R&D Factory as an example, this facility primarily manufactures high-end mobile phones. By integrating AI technology and large-scale model services, the factory's production efficiency has soared. What once required 80 personnel on the production line now necessitates only 14, and the production cycle for a high-end mobile phone has shrunk from hours to just 20 seconds. This efficiency surge not only yields higher output and lower costs for Huawei but also fortifies its global market competitiveness.

The Path is Clear: Huawei's Collaborative Journey with Manufacturers

Huawei is acutely aware that the manufacturing industry underpins the national economy. Only through digital and intelligent transformation can the country advance from a manufacturing power to a superpower. Therefore, Huawei will persist in deep-diving into technological R&D, experience accumulation, and ecosystem development. Through close collaboration with manufacturing enterprises, Huawei not only shares its technology and management expertise but also aids partners in achieving digital and intelligent upgrades and business innovation through tailored solutions and continuous technical support.

In partnership with Changan Automobile's digital and intelligent factory, Huawei constructed a solid digital and intelligent foundation through the "one cloud, one network, one platform" smart factory solution's new architecture, helping Changan Automobile connect engineering data flows, commercial information flows, and production supply flows to expedite product data transmission and agile order response.

Beyond manufacturing processes, Huawei also collaborates with numerous leading automotive companies in digital R&D. Based on the data mainline, a digital and intelligent R&D platform has been established, fostering efficient collaboration in the R&D process and substantially reducing the R&D cycle. This has helped cut new model R&D cycles by 25% and R&D costs by 15%. Additionally, in after-sales service, leveraging Huawei's large model technology and AI computing power, it aids automotive companies in building after-sales maintenance knowledge graphs, shortening technician training cycles, and helping automotive companies reduce costs and enhance efficiency.

In biopharmaceutical enterprises, Huawei employs the Pangu pharmaceutical molecule large model to accelerate drug R&D through scientific computing, shortening the new drug R&D cycle, lowering R&D costs, and markedly improving new drug R&D success rates.

Behind these successful cases lies Huawei's profound accumulation and innovative prowess in digital and intelligent transformation. Huawei not only shares its technology and management expertise with partners but also empowers them to achieve digital and intelligent upgrades and business innovation through continuous technical and solution support.

Manufacturing Enterprises Embrace the 'New' Through Digital and Intelligent Transformation

For manufacturing enterprises navigating digital and intelligent transformation, Huawei's experiences and suggestions offer invaluable insights. Firstly, manufacturing enterprises must articulate the strategic positioning and goals of their digital and intelligent transformation, seamlessly integrating it with the enterprise's core business to ensure tangible value from the transformation. Secondly, they must prioritize data governance and security, establishing a robust data management system and security mechanism to provide a solid foundation for digital and intelligent transformation. Lastly, manufacturing enterprises should actively seek collaboration opportunities with industry leaders, accelerating their digital and intelligent journey by adopting advanced experiences and technologies.

Moreover, manufacturing enterprises should explore the application potential of new technologies like AI in digital and intelligent transformation. By integrating AI technology, they can achieve intelligent production process upgrades and automated business process optimization, further bolstering their competitiveness and market responsiveness.

Looking ahead, Huawei will continue to delve deeply into technology, fully leveraging the advantages accrued from over 30 years of intense R&D investment to provide a solid technical foundation for manufacturing enterprises on their digital and intelligent transformation path. This will free manufacturing enterprises from software and hardware technological constraints, enabling them to access world-leading hardware and software infrastructure services. Concurrently, Huawei will continue to propel its own digitalization and intelligentization process, transforming the valuable experiences gained into service capabilities to empower more manufacturing enterprises, jointly advancing the high-quality development of China's manufacturing industry.