Borg 01: Detroit Robotics Startup Unveils Modular Design Innovation

![]() 03/18 2025

03/18 2025

![]() 522

522

Produced by ChiNeng Tech

Detroit-based startup Borg Robotics has introduced its modular humanoid robot, Borg 01, alongside an integrated industrial automation ecosystem encompassing automated pallet trucks, forklifts, and mobile robots. This holistic approach offers factories and warehouses comprehensive automation solutions without the need to alter existing workflows.

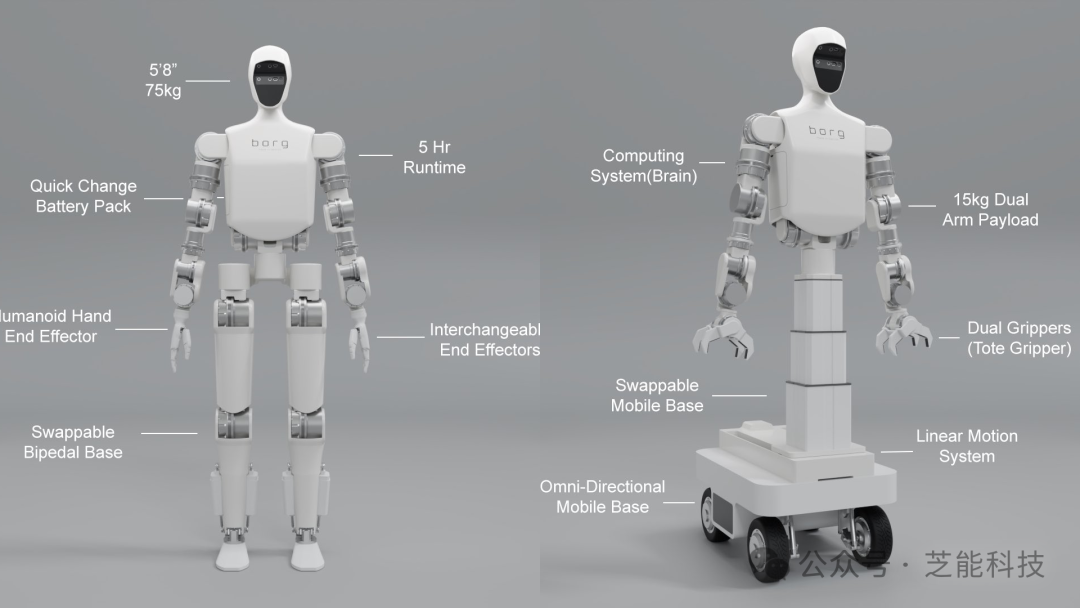

Borg 01's standout feature is its modular design, enabling seamless transitions between wheeled and bipedal bases and the autonomous adaptation of end-effectors to diverse tasks.

Nestled in Detroit, Borg Robotics capitalizes on the city's automotive manufacturing resurgence and the potential benefits of the Trump administration's "America First" policy. Amidst a U.S. manufacturing industry facing a labor shortage of up to 1.9 million, Borg's automation solutions could prove pivotal.

This article delves into Borg's technological innovations, Detroit's geographical advantages, and its strategic positioning in the humanoid robot industry, exploring its impact on industrial automation.

01

Borg Robotics' Technological Innovations and Strategic Positioning

Borg Robotics' flagship product, Borg 01, is a humanoid robot tailored for industrial applications, distinguished by its modular design. The robot can autonomously switch between a wheeled and bipedal base, facilitating efficient movement on flat surfaces and agile operation in complex environments.

Equipped with interchangeable end-effectors such as vacuum grippers and five-finger hands, Borg 01 can autonomously adjust tools according to task requirements, making it versatile for tasks ranging from assembly lines to warehouse handling.

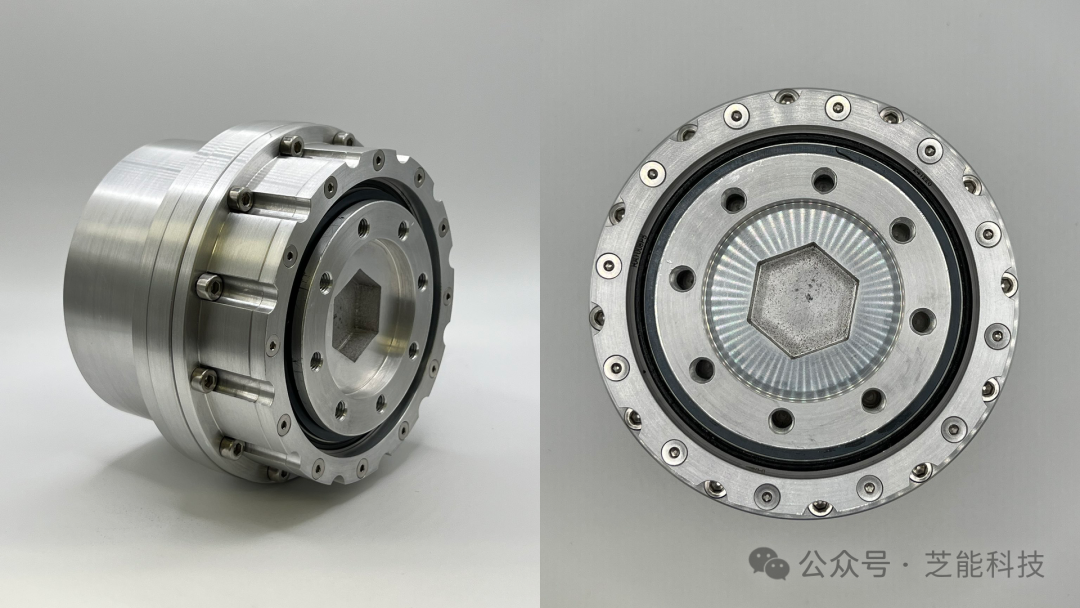

Borg 01's technological prowess is also evident in its core component, the Borg Actuator 01, an internally developed actuator weighing just 720 grams but capable of delivering a torque of up to 160 Nm. This lightweight, high-performance design imparts exceptional agility and load capacity to Borg 01.

Standing at 5 feet 7 inches (approximately 170 cm), Borg 01 is designed for narrow spaces and can maneuver freely in crowded factory settings. Its seamless integration with automated pallet trucks facilitates a smooth transition from cargo handling to fine assembly, showcasing its real-world application potential.

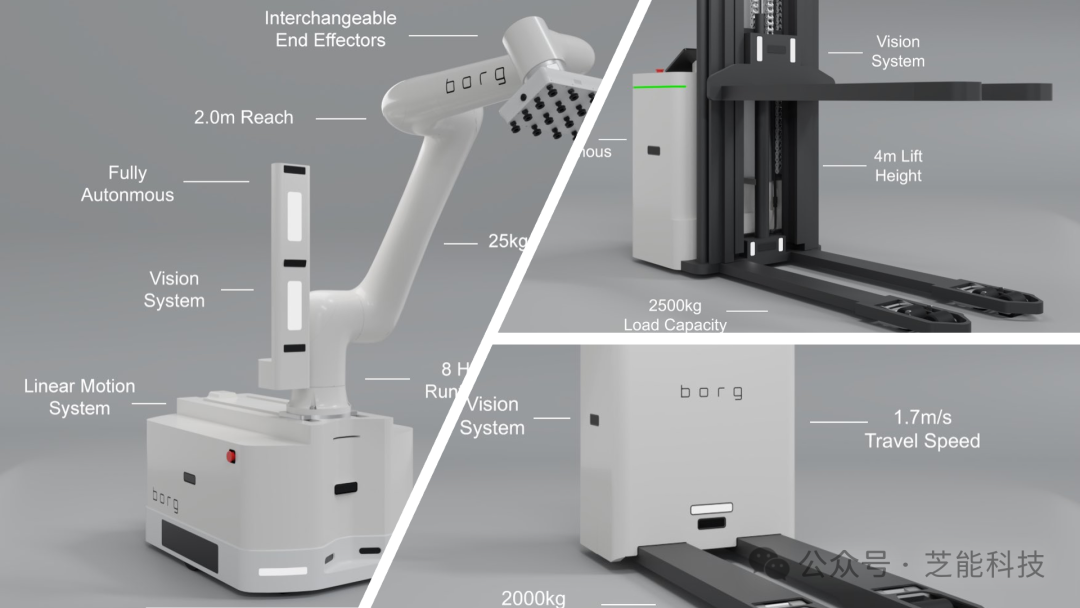

Borg Robotics' focus extends beyond a single humanoid robot to the creation of a comprehensive industrial automation ecosystem comprising:

◎ L.01 Pallet Truck: An AI-integrated autonomous pallet truck equipped with high-load omnidirectional wheels capable of handling pallets up to 2.5 tons. Its automatic fork width adjustment feature accommodates different-sized pallets, with a fixed fork width option for economic efficiency.

◎ LX.01 Automated Forklift: Capable of lifting 2.5 tons to a height of 4 meters, suitable for narrow-space cargo handling. Future iterations will increase this height.

◎ i.01 Mobile Robot: Designed for warehouses, it autonomously scans inventories up to 7.5 meters high (next-gen versions will reach 12 meters), enhancing inventory management efficiency.

These robots are interconnected via AI and can collaborate seamlessly. For instance, L.01 transports pallets to designated locations, with Borg 01 taking over for complex operations. This ecosystem design offers a one-stop automation solution, significantly reducing the cost and complexity of integrating new technology into factories.

Unlike humanoid robot companies like Tesla Optimus or Figure AI, which pursue generalized intelligence, Borg Robotics is explicitly focused on industrial automation. Their vision is to "achieve industrial automation through AI-driven robots," positioning humanoid robots as integral parts of the automation system rather than comprehensive intelligence platforms.

This strategy enables Borg to swiftly penetrate the manufacturing and logistics markets, addressing specific challenges such as labor shortages and inefficiencies in highly repetitive tasks.

Borg emphasizes the seamless integration of its products with existing manufacturing processes. Borg 01's modular design allows direct integration into production lines without altering work cell layouts, appealing to traditional manufacturing enterprises averse to costly renovations.

Borg plans to launch three robots (Borg 01, pallet truck, and an unannounced product) in the second quarter of 2025, underscoring its commitment to rapid commercialization.

Borg 01's modular design and lightweight actuator provide significant technological advantages over traditional fixed industrial robots, offering greater mobility and versatility. In automotive manufacturing, it can be used for parts handling, welding assistance, or final assembly processes. Its optional four-arm configuration further expands application scenarios, such as simultaneous operation of multiple tools or handling complex components. Borg's ecosystem targets factory-wide automation.

For example, L.01 and LX.01 optimize material flow, i.01 enhances inventory management efficiency, and Borg 01 fills gaps where human flexibility is required. This comprehensive solution is poised for wide application in industries like automotive, aerospace, and heavy industry.

02

Detroit's Manufacturing Revival and the Competitive Landscape in the Humanoid Robot Industry

Detroit hit rock bottom in 2013 due to municipal bankruptcy but has gradually recovered with the resurgence of the automotive industry.

GM, Ford, and Stellantis, the city's three automotive giants, remain the economic backbone, driving employment and investment growth. By 2024, Michigan's automotive manufacturing sector had recovered to about 300,000 jobs, accounting for over 20% of U.S. automotive employment.

Detroit is also fostering the "Advanced Mobility Industry" through technologies like driverless cars, eVTOLs (Electric Vertical Take-Off and Landing Aircraft), and robots to bolster its global competitiveness.

By establishing its headquarters in Detroit, Borg Robotics leverages this manufacturing ecosystem, being close to the three major automotive players and quickly accessing real-world scenario requirements and customer feedback. For instance, Ford plans to deploy more automation equipment in its North American factories by 2026, positioning Borg's solutions as a potential top choice.

The political environment is also crucial for Borg's development. The Trump administration's promise to protect U.S. manufacturing through high tariffs and promote "Made in America" could stimulate automotive companies to increase domestic investments, potentially boosting demand for Borg robots.

Meanwhile, the U.S. manufacturing industry faces an increasingly severe labor shortage. A Deloitte report predicts a shortage of 1.9 million workers by 2033, particularly in repetitive and arduous roles.

Borg's humanoid robots address this gap, with Borg 01 replacing manual labor for heavy-duty tasks on production lines, and L.01 and LX.01 optimizing logistics efficiency, reducing enterprises' reliance on human labor.

The humanoid robot industry presents two development paths:

◎ One is the pursuit of generalized intelligence, exemplified by Tesla Optimus and Figure AI, aiming to create versatile, high-AI-capability robots for cross-industry applications. However, this path is fraught with high technical barriers and a lengthy commercialization cycle.

◎ The other is the vertical application path, adopted by Borg Robotics and Agility Robotics, focusing on industrial and logistics scenarios, emphasizing efficiency and reliability, and striving for rapid implementation.

Borg has chosen the latter path, with its modular design and ecosystem strategy making it more competitive in industrial scenarios.

◎ Compared to Boston Dynamics' Spot (a versatile quadruped robot), Borg 01 is more focused on manufacturing tasks.

◎ Compared to Agility Robotics' Digit (for logistics handling), Borg offers a more comprehensive automation solution.

This "specialized and refined" positioning could enable Borg to achieve profitability in the short term.

However, Borg also faces challenges:

◎ Firstly, Borg 01's durability and performance need to be validated through large-scale deployments.

◎ Secondly, with numerous humanoid robot startups competing for market share, Borg must establish a firm foothold in 2025.

◎ Finally, as a startup founded in 2023, Borg requires continuous funding to support research, development, and promotion.

Nevertheless, with local resources, practical designs, and policy support, Borg is expected to make significant strides in the coming years.

Summary

Borg Robotics' emergence has invigorated Detroit's manufacturing industry and paved a new path for the commercialization of humanoid robots. Its modular humanoid robot, Borg 01, and integrated industrial automation ecosystem, centered on practicality and integration, precisely meet the manufacturing industry's transformation and upgrading needs.

Against the backdrop of Detroit's automotive industry recovery and the U.S. manufacturing labor shortage, Borg has seized a historic opportunity.

The product launch in the second quarter of 2025 will be a pivotal moment for Borg, demonstrating its reliability and cost-effectiveness in real-world applications. Borg is poised to emerge as an industry dark horse, propelling humanoid robots from concept to large-scale application.