Is IPD the Panacea for Manufacturing?

![]() 07/19 2024

07/19 2024

![]() 689

689

As a major manufacturing country, the digital transformation of manufacturing enterprises has been underway for quite some time. However, for many enterprises with complex project processes and overwhelming management burdens, they are trying to solidify successful experiences into reusable process systems.

On July 17th, Feishu Projects launched an IPD product solution aimed at the manufacturing industry, hoping to help enterprises implement the IPD concept through the collaborative genes of Feishu Projects.

Nielsen once collected a brutal statistic: in China, two new products are introduced to the market every hour on average, but at the same time, at least two products exit the market every hour. The average success rate of new product launches in the FMCG (Fast-Moving Consumer Goods) industry is below 5%, and the average duration of a new product is only nine months.

Creating a blockbuster product is every product person's dream, but the reality is that a large number of products sink beneath the iceberg.

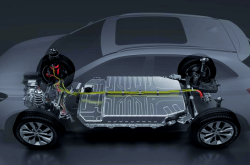

On the other hand, we also see many products that win repeatedly. For example, in the new energy sector, NIO has achieved success with consecutive models from ES8 to ES6 and then to its first sedan, ET5. In the consumer electronics industry, Huawei's phones, since the P6, have seen almost every Mate and P model become a hit, firmly establishing itself in the high-end mobile phone market.

Whether it's NIO or Huawei, they share a commonality in product development: building products based on the IPD development process to gain insights into user needs and respond quickly, thereby achieving business success.

The fundamental idea of IPD is to streamline responsibilities and rights, solidify processes, and bring together R&D, business, and related functional personnel to jointly take responsibility for the full lifecycle development and operation of products. Ultimately, it enables enterprises to "do the right things," "do things right," and sustain operations, transforming product development from accidental success to inevitable success.

01

The Pain of Project Management in Manufacturing

Behind the difficulty in creating blockbuster products often lies the pain of project management.

Especially in the manufacturing industry, where investments are large and R&D cycles are long, problems cannot be patched like software. Once there are quality issues or products do not meet market demand, enterprises will face huge recall costs and inventory pressures.

In the actual product development process, many challenges arise. For example, processes are not transparent, lacking digital tools and structured cross-departmental processes, with departments relying on manual coordination. Decision-making is difficult to support, with data scattered across systems, reviews becoming mere formalities, and opinions difficult to summarize. Resource supervision is challenging, with uncontrollable input and output. Execution cycles are long, and new changes cannot be flexibly configured into processes.

But each link seems to have its grievances. Bosses lack sufficient data and information support, making decision-making difficult. Project managers also suffer, unable to push forward various links of the project. Sub-project team members complain that requirements keep changing, so they prefer to remain stagnant, taking a wait-and-see approach.

These problems all point to a lack of systematic standards and controls in project processes.

For example, many enterprises used to manage through offline spreadsheets, emails, documents, and other tools, with project managers relying on Excel for task inventory and manually tracking project progress during execution.

Even with IT systems, the silo effect is evident. Currently, many manufacturing enterprises primarily use PLM systems to coordinate product R&D work and then use Feishu, DingTalk, or WeChat for daily communication. This fragmented approach is common in the manufacturing industry.

The problems with this approach, besides untimely information synchronization and low transparency, include cumbersome system entry operations that do not support mobile devices. After entry, relevant personnel are often not promptly notified, leading to situations where projects have already started but have not been entered into the system, making it impossible to fully track input costs.

Newland Payment Technology focuses on payment terminals, deploying over 100 million devices across more than 120 countries globally. In Newland's business scenarios, user needs come from various channels and are stored in different systems, making effective management and analysis difficult. The progress and effectiveness of various links cannot be evaluated, and teams have varying perceptions of the value of requirements, resulting in a significant waste of communication costs during the process.

Early Huawei also faced similar issues. Due to a lack of systematic rules and solidified processes, R&D, marketing, production, service, and other departments operated independently, with poor communication between departments. This not only led to high R&D costs and waste but also high product failure rates. Success relied on luck and the individual abilities of a few heroes, rather than being sustainable. However, high gross margins in the telecommunications industry and rapid industry development masked many of these problems at the time.

Today, however, as market competition intensifies and organizational processes become increasingly complex, these problems are further amplified, making it even more difficult to create blockbuster products.

02

How to Do the Right Things and Do Things Right

"Liquid eyeshadow. During the development phase, no channel expressed interest in selling this product, so the project was canceled, with nearly 20 person-days invested."

"Lip gloss project encountered color change and color band risks after stability testing. It is not recommended to use transparent packaging materials. Incomplete evaluations during the early development stage led to subsequent shipments with issues."

"The makeup remover project was concluded without convening a key review meeting, resulting in incomplete evaluations and shipments with issues, necessitating a full recall of the batch."

Such issues frequently occurred during the product development process at the cosmetics brand Marie Dalgar. Each mistake not only resulted in sunk costs but also missed business opportunities. "Out of seven ideas, only one achieves success. Out of four development projects, only one achieves commercial success."

IPD, as an advanced product development concept and methodology,Its core idea is to make products market-oriented and customer-centric, helping businesses to do the right things and to do things right. focuses on making products market- and customer-centric, helping enterprises do the right things and do things right.

After two years of development, Feishu Projects launched the IPD product solution on July 17th, targeting manufacturing enterprises with digital upgrade needs. These enterprises are characterized by long product cycles, complex development processes, and multiple product lines.

Positioned as a digital expert in IPD processes, Feishu Projects' IPD product solution plays the role of a skeleton, connecting various systems and departments within the enterprise.

Hong Tao, head of Feishu Projects, told Digital Intelligence Frontline that there are mainly three types of IPD solutions used by customers before: one is that very large companies attempt to develop their own solutions to meet business needs; the second is specialized R&D management tools for manufacturing, primarily customized solutions; the third is neither self-developed nor customized tools, relying primarily on individuals to connect business processes.

However, all three have common pain points, such as inflexibility, requiring redevelopment for new needs; and weak collaboration efficiency, tending towards individual use. Feishu Projects is based on the Feishu system, which is known for its strong collaboration capabilities.

Compared to existing IPD tools, Feishu Projects' newly launched solution has three highlights:

First, comprehensive digitization. Xu Zhijun, rotating chairman of Huawei, once said that processes without IT support easily become a pile of paper, difficult to execute. In the past, everyone relied heavily on offline meetings and documents, but now Feishu Projects integrates process configuration and project management on a digital platform, achieving comprehensive digitization through integration and being integrated.

Feishu Projects has a natural advantage in this endeavor, as Feishu started as an instant messaging platform and later launched widely acclaimed Feishu Docs and multi-dimensional tables, giving Feishu Projects inherent strengths in daily communication and document and data integration.

One effect of comprehensive digitization is process visualization. Currently, most project management tools allow individuals in each process node to see only their role in that node, making it impossible to see overall progress, leading to high communication costs due to information opacity.

A distinctive feature of Feishu Projects is the swimlane diagram, which provides a clear and intuitive view of the overall process and progress, enabling everyone to do things right. This capability is not yet available in other tools. Moreover, Feishu Projects IPD enhances the existing tables, kanban boards, and Gantt charts with tree and panoramic views.

For example, Ruijie Networks used Feishu Projects to transfer offline processes online, solidifying access criteria, activities, tasks, deliverables, etc., into the system, creating a battle map that allows Ruijie employees to always know the current project stage and arrange their work content accordingly. A set of work standards transforms operational norms during R&D into specific standard actions to ensure consistent understanding among team members. A set of best practices solidifies various project types such as hardware, in-house R&D, and software into process templates, making project experience the best practices within the organization and allowing teams to learn from each other.

With Feishu Projects, Newland Payment Technology sorted out a process system from demand to R&D, connecting the four major links of demand collection, analysis, distribution, and implementation. Through this transparent and standardized operation, they reduced the demand change rate by 20%.

Second, flexible adaptability. IPD processes emphasize moving from rigidity to optimization to solidification. Rigidity aims to unify thinking, optimization involves correction during problem-solving, and solidification institutionalizes achievements. This means processes are not static and need to be continuously adjusted based on product development.

Currently, many manufacturing IPD processes are rigid, requiring full replication when applied to a new project. However, Feishu Projects, derived from the development of agile products like Douyin, is characterized by modularity, allowing processes to be flexibly adapted to project needs.

Third, comprehensive end-to-end coverage. Product development does not mark the end of the process; subsequent stages include marketing, sales, and service. Feishu Projects proposes IPD+, a concept of continuous operation, achieving overall end-to-end coverage.

A blockbuster product cannot rely solely on a first-class product but also requires first-class marketing services. Traditional project management tools often use independent systems, resulting in disconnects between marketing and service plans and manufacturing progress. Management lacks a global perspective, with information transmission heavily reliant on individuals. Frontline needs cannot be promptly addressed by R&D, and product specification changes cannot be promptly communicated to the market for adjustments.

Marie Dalgar coordinates the key milestones of the IPMS main business flow with the IPD main business flow. IPMS includes market area activity views required by IPD and supports IPD by calling upon key marketing conclusions.

With the help of Feishu Projects, Marie Dalgar's parent company, Chuangyuan Group, connects interfaces with different systems such as PLM, MDM, and ERP to ensure information flow between the IPD process and upstream and downstream master data, further promoting interoperability with systems like HR to achieve end-to-end lifecycle management from product planning to product withdrawal.

Under the IPD management system, managers can take a global perspective, aligning market operations with product development processes to manage products end-to-end. Marketing and service teams can visualize process implementation, lower internal communication barriers, avoid resource waste, and quantify organizational output. Product R&D teams can obtain timely market feedback and communicate important changes, enabling cross-domain collaboration.

It is not difficult to see that from comprehensive digitization to flexible process configuration to comprehensive end-to-end coverage, Feishu Projects has captured the three core elements of enterprises in creating blockbuster products, helping them do the right things and do things right.

03

Is IPD the Panacea?

As a business management system and methodology, IPD has gained popularity domestically and internationally since its success at companies like IBM and Huawei. Nearly 80% of Fortune 500 companies apply IPD. According to PRTM consulting data, the IPD model can shorten the time from product investment to launch by 40% to 60%, and increase the percentage of total product revenue from new products to 100%.

Before the launch of Feishu Projects' IPD product solution, there have already been many tools exploring ways to help enterprises apply IPD, "with more and more vendors wanting to enter this field."

However, doubts about IPD have always existed within the industry, and many enterprises face the problem of low IPD success rates. The most typical example is Huawei's IPD, which other companies find difficult to learn or implement. Many enterprises start with high ambitions but soon lose momentum.

Xiao Kunhua has experienced IPD transformations in two companies. He believes that the IPD development concept is more suited to serving enterprises with complex processes and overwhelming management burdens. "If the management level has not encountered this problem, introducing another IPD system would be creating difficulties where none exist," Xiao Kunhua told Digital Intelligence Frontline.

IBM had a classic saying – making elephants dance. "If this company is currently the size of an ant, does it need to learn the process of an elephant dancing?"

Xiao Kunhua found that maintaining processes itself requires a significant amount of effort, which is generally beyond the capacity of small companies. For example, in concrete implementation, IPD generates workload for individuals, requiring the completion of many process reports and reviews, "which is also a relatively complex process," leading many people to be reluctant to follow IPD requirements.

So, what are the reasons that plague enterprises in implementing IPD, or where are things not done properly?

First, digital transformation is generally considered a "top-down project," and IPD implementation is even more so, as it involves multiple departments and stakeholders across the entire company. If the boss lacks sufficient determination, it is easy for the transformation to fail and revert to the old way.

When Huawei implemented IPD, it not only spent over a billion dollars but also had a strong promoter in its founder, Ren Zhengfei, who even elevated IPD to the level of the company's survival. Not only did the R&D department need to respond, but all departments had to be involved in IPD. "If you understand, you take up the position; if not, you step down. That's our principle, or we can't make improvements," Ren said.

Therefore, some insiders point out that without a change in mid-to-high-level thinking, relying on software systems and tools to change an enterprise is unrealistic.

Second, IPD product development is an investment behavior, not a technical behavior. This means that it is not solely about whether the product itself can be realized but rather emphasizes examining the development process from an investment perspective. If the input-output ratio is low or other issues arise, decision reviews can be conducted to decide whether to terminate the project.

Third, it is not necessary to fully implement IPD from the start. IPD construction can be large or small, tailored to the company's size and its own issues.

For example, Chuangyuan adopts an iterative model, starting with small-scale product innovation in marketing and R&D departments, prioritizing the introduction of products into IPD, and then gradually expanding coverage to other departments and scenarios, minimizing trial and error costs and maximizing project benefits.

Finally, IPD is not static; it is a continuously evolving process. For example, while reviews have benchmarks, the company's financial, material, and human resources may not always meet these ideal conditions, necessitating process and node tailoring.

Since 1999, Huawei has undergone nine major upgrades to its IPD process system, optimizing almost every year. When Lixiang Auto implemented IPO changes, it was clear that organizational changes could not be achieved overnight.

Based on its powerful underlying workflow engine capabilities, Feishu Projects creatively solves this challenge, for example, by identifying problems through metrics insights and initiating process improvements and optimizations at any time. All running projects can be upgraded to the latest process template with a single click in the foreground, a process that takes only a few seconds. At the same time, excellent practices within the organization can be preset as resource libraries, allowing excellent processes to be quickly referenced and learned, flexibly adapted to different projects. With this method, enterprises can transform every practical accumulation into shareable digital knowledge, benefiting all employees involved in the IPD process within the enterprise.

For example, SKG, which specializes in smart wearable devices, used Feishu Projects' capability to tailor review elements, reasonably pruning unnecessary elements based on product realities. Newland Payment Technology leveraged Feishu Projects' powerful customization capabilities to independently build suitable operational tools, which previously required significant development work but can now be easily configured to build business systems.

Admittedly, there is no one-size-fits-all secret weapon for creating blockbuster products. However, the IPD system and ideology are valuable and necessary for enterprises with complex processes and organizations today.