Accumulate and Strike: Leapmotor's Evolution from Autonomous Engineering to Systemic Expansion

![]() 07/14 2025

07/14 2025

![]() 462

462

Produced by Zhineng Zhixin

Behind the launch of the refreshed C11 in July 2025, Leapmotor's strategic focus has broadened beyond products alone, encompassing a systematic approach to scaling for the next phase. This includes product definition, cost systems, R&D capabilities, channel strategies, and globalization paths.

Renowned for its "engineer culture," the company aims to transform from a cost-effective technology provider into a fully-fledged automaker with systemic integration capabilities, targeting the mainstream market. The C11 serves as a stepping stone on this journey and may well be the catalyst for an even greater transformation.

Part 1

Deepening and Expanding the Engineer Culture: The Evolution of C11

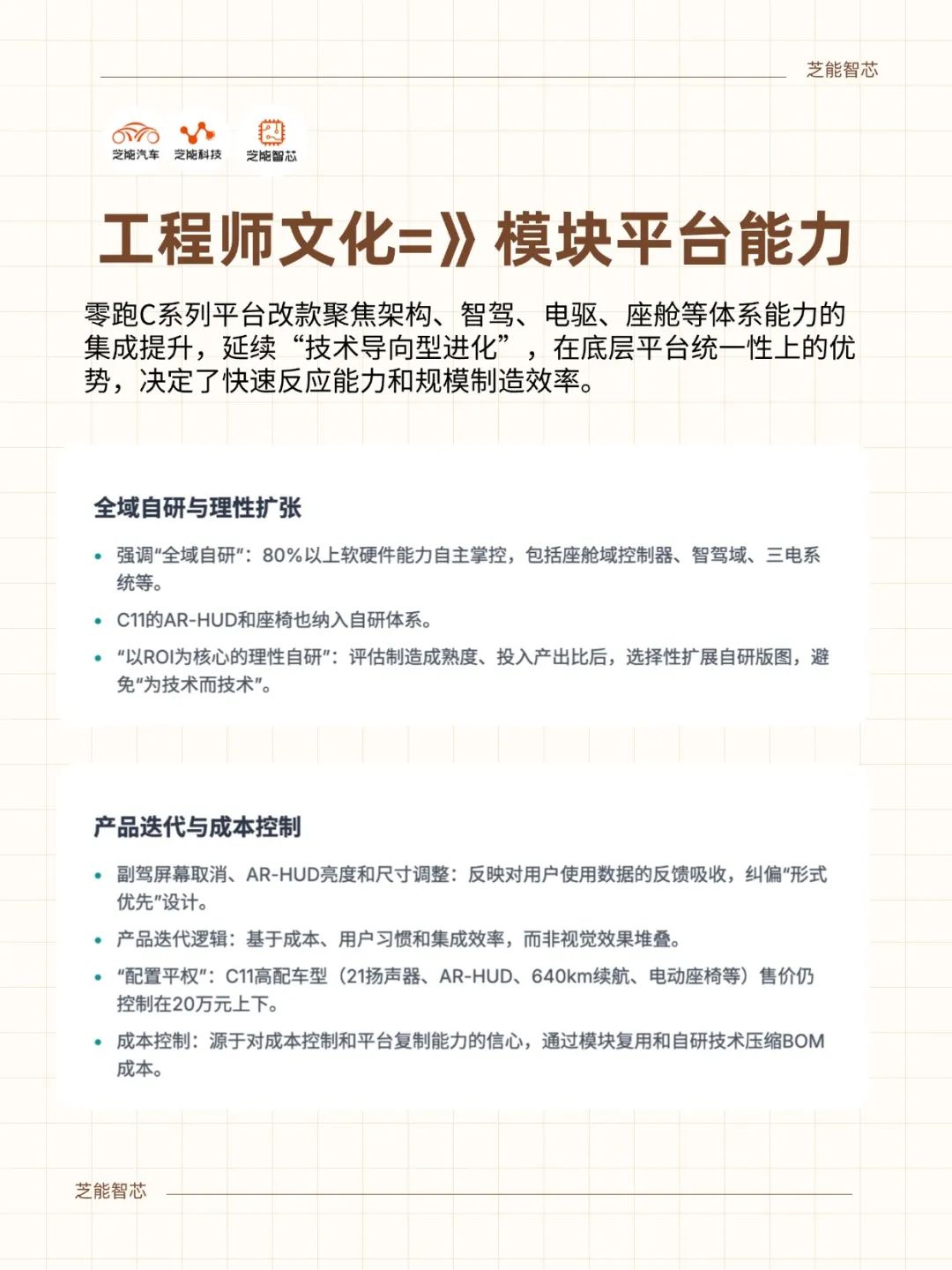

The mid-cycle refresh of the Leapmotor C11 did not dazzle with a "revolutionary" design but rather emphasized the holistic enhancement of system capabilities, including architecture, autonomous driving, electric propulsion, and the cockpit, adhering to its consistent "technology-driven evolution."

The swift deployment of the 800V platform, silicon carbide electric drive, and LEAP3.5 autonomous driving system across its model lineup underscores its underlying platform uniformity. This advantage transcends mere technical specifications, underpinning Leapmotor's rapid response and mass production efficiency.

Leapmotor underscores its foundation in "full-stack R&D," with over 80% of software and hardware capabilities under its control, encompassing cockpit domain controllers, autonomous driving systems, and electric drivetrains. The AR-HUD and seats in the current C11 have been further integrated into its R&D ecosystem.

Rather than blindly pursuing "full in-house manufacturing," Leapmotor selectively expands its R&D territory after assessing manufacturing maturity and cost-benefit ratios. This "ROI-centric, rational R&D" strategy avoids the pitfall of technology for technology's sake, aligning more closely with commercial logic.

The removal of the co-pilot screen and adjustments to the brightness and size of the AR-HUD reflect Leapmotor's incorporation of user feedback based on usage data.

The shift from a triple-screen setup to a more practical in-cabin interaction interface represents a correction of past "form-over-function" cockpit designs. Leapmotor replaces "trendy marketing jargon" with an "engineer's mindset," prioritizing cost, user habits, and integration efficiency over visual spectacle in product iteration logic.

This emphasis on system capabilities ensures that C11, as Leapmotor's first model with a million-user base, does not rely on "volume-driven price cuts" but earns consumer recognition through "value-for-money configurations."

For instance, the high-end C11 model, featuring 21 speakers, AR-HUD, a 640km range, and electric seats, is priced around 200,000 yuan. This reflects Leapmotor's confidence in cost control and platform replication capabilities.

Beneath this product logic lies a clearer strategic vision: driving continuous product competitiveness through frequent platform evolutions and compressing BOM costs through module reuse and in-house technology.

In this model, the phrase "cost-based pricing" transcends mere price reductions, embodying a value redistribution grounded in platform capability advantages.

◎ Leapmotor adheres to its engineer culture, leveraging module platform capabilities as the cornerstone for rapid evolution;

◎ The expansion of R&D scope prioritizes ROI over the "full-stack myth";

◎ Product configurations emphasize practicality over visual spectacle, reflecting an engineering-centric approach;

◎ Cost control stems not from compression but from technical structure optimization and platform integration efficiency enhancements.

Part 2

At a Crucial Juncture: The "Liberation War" in Organization, Channels, and Capital

From technology building to commercial competition, Leapmotor's stance has unequivocally shifted to a "fully market-oriented combat" mode.

It aims for a sales target of 500,000 units in 2025, having achieved 220,000 units in the first half and shipped over 20,000 units overseas, signifying a stable expansion cycle in organizational structure, manufacturing capabilities, and channel efficiency.

More critically, it defines the "next three years" as a pivotal window for achieving profitability and market share expansion. Strategic planning is no longer survival-focused but guided by the dual objectives of "scale and profitability."

The channel system is pivotal in assessing its expansion capabilities.

Data reveals that while the number of Leapmotor stores has declined, sales have doubled, underpinned by optimized channel structure and efficiency. Traditional supermarket channels are gradually being phased out, with auto malls and 4S outlets in core cities emerging as the mainstay. Coupled with the transition to a hybrid sales model, the ROI has improved.

This underscores that Leapmotor's channel strategy no longer hinges on extensive coverage but rather on quality density and investment returns.

In supply chain management, Leapmotor emphasizes long-term partnerships with top-tier component suppliers, optimizing costs through "strategic cooperation pricing."

This approach appears more resilient amidst industry-wide "price negotiations," emphasizing not cost advantages through price cuts but low costs through high efficiency, high integration, and autonomous capabilities. These are the underlying competitive logics that distinguish Leapmotor from other automakers.

Financially, Leapmotor is nearing breakeven, having achieved its first quarterly profit in Q4 2024, albeit with slight fluctuations in Q1 2025.

According to forecasts, profitability for the full year of 2025 remains a strategic priority, with an expected total delivery of 47GWh of power batteries and operating revenue reaching 24 billion yuan. Coupled with data showing a 48% year-on-year decrease in in-house manufacturing costs, a 28% reduction in scrap rates, and a yield rate exceeding 96%, it indicates that Leapmotor's manufacturing management system is transitioning from initial maturity to continuous optimization.

Leapmotor's founding team refers to the current stage as the "Liberation War," with a clear objective: a systemic evolution from "survival" to "thriving," emphasizing organizational capabilities, profit models, and long-term sustainability.

This explains Leapmotor's investment in overseas factories (e.g., in Thailand) and plans to increase overseas shipments by 94% in 2025, raising the proportion to 26% of total sales.

◎ Leapmotor stands at a critical juncture, transitioning from breakeven to sustained profitability;

◎ The channel strategy shifts from extensive coverage to efficiency-focused optimization;

◎ Maintains a "strategic cooperation + cost-sharing" logic with the supply chain;

◎ A full-stack product platform and cost system have been established, enabling scale replication.

Summary

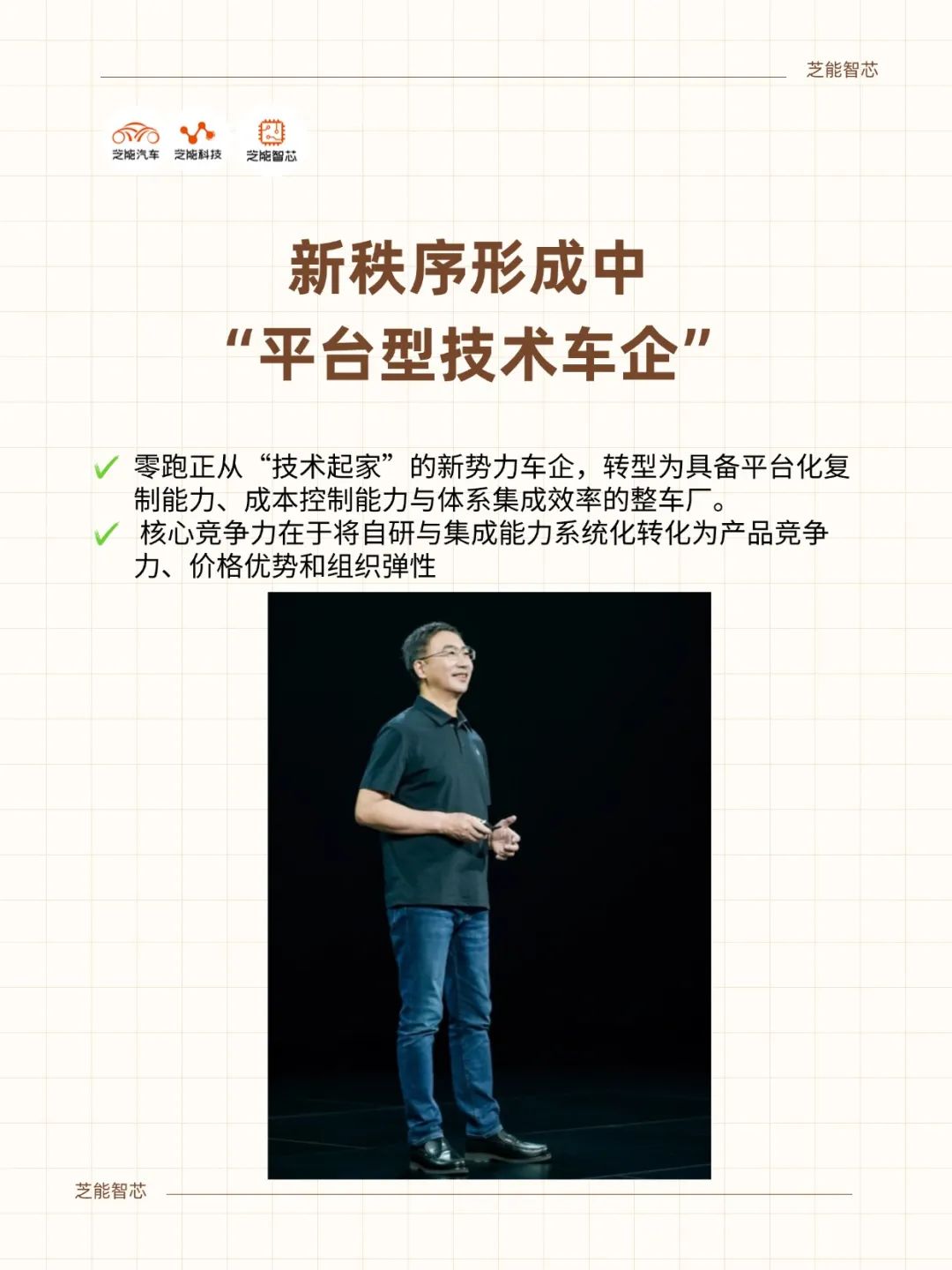

Leapmotor is transforming from a "technology-centric" new energy automaker to a full-fledged vehicle manufacturer with platform replication capabilities, cost control prowess, and systemic integration efficiency. Its core competitiveness now lies not in singular technological advancements but in systematically converting R&D and integration capabilities into product competitiveness, price advantages, and organizational agility.

Leapmotor's journey mirrors that of a manufacturing enterprise with a strong science and engineering background, seeking a dynamic balance between market scale and technological expansion. The "engineer culture" permeates product definition, manufacturing systems, channel management, and organizational strategies. The next three years will determine whether Leapmotor possesses the staying power to enter the mainstream market, not reliant on a single hit product but rather on platform expansion, organizational stability, and profit efficiency.