Blowing up, rolling, freezing, falling... Is selling a car so desperate?

![]() 09/29 2024

09/29 2024

![]() 544

544

Original by New Energy Outlook (ID: xinnengyuanqianzhan)

In today's world where new energy vehicles are all the rage, the safety and reliability of vehicles remain a top priority for everyone.

To reassure consumers in choosing new energy vehicles, major automakers have resorted to various extreme tests. These tests not only showcase the performance of vehicles under extreme conditions but also provide consumers with a more intuitive and engaging understanding of the safety of new energy vehicles.

From bullet-shooting batteries to high-altitude drops, from rollover tests to ultra-low-temperature freezing, these extreme tests are truly a collection of "torture tests" for vehicles.

It seems automakers feel embarrassed to sell cars without conducting some extreme tests! These crazy tests not only showcase automakers' commitment to safety but also allow us to experience the endless possibilities brought by technology. So, the next time you see a new energy vehicle, imagine the "hellish" tests it has endured and sit back comfortably to enjoy the ride!

1. Embarrassed to sell cars without some extreme torture tests

These extreme tests are akin to the automotive world's version of "Survivor," showcasing various forms of vehicular torture that leave one stunned. But don't mistake them for mere spectacles; they reflect automakers' relentless pursuit and validation of vehicle safety performance.

Take the recently launched JIYUE 07, for example. It underwent a 45-degree slope rollover test, simulating a vehicle's uncontrolled rolling in the wild. Despite the rollover, its body structure remained intact, doors opened normally, and multiple airbags deployed promptly.

Evidently, it demonstrates to consumers that its doors will not remain shut in the event of a traffic accident.

Another pain point in using new energy vehicles is severe cold weather, which significantly compromises vehicle performance. In some cases, doors even freeze shut, rendering the car unusable. JIYUE 07 underwent a freezing test in -18°C temperatures. The result? It started effortlessly, and battery life remained unaffected. This is thanks to its advanced battery heating system, which automatically activates to maintain optimal battery temperature, ensuring smooth travel even on the coldest days.

Meanwhile, Xingjiyuan ET conducted a high-altitude drop test, suspending the car from a height of 32 meters and allowing it to free-fall, akin to jumping from an 11-story building. While the exterior bore the brunt of the impact, the interior structure remained solid, and the dummy models inside indicated good occupant protection.

Photo/Top: JIYUE 07 Freezing Test Bottom: Xingjiyuan High-Altitude Drop Test

Source/Internet Screenshot from New Energy Outlook

Xiaomi SU7 went even further, shooting bullets at its battery to test safety. Remarkably, the battery emerged unscathed, neither catching fire nor exploding, exceeding expectations. This test undoubtedly bolstered confidence in the safety of new energy vehicle batteries.

JETOUR Shanhai T2 offered a visual spectacle with a fireworks and explosive blast test. Four packs of explosives were buried beneath the car, surrounded by 50 sets of 950 fireworks. When ignited simultaneously, the car was propelled into the air, soaring over a meter high. Nevertheless, the passenger compartment remained intact, showcasing its exceptional structural strength and occupant protection.

Photo/Top: JETOUR Shanhai T2 Bottom: Xiaomi SU7 Bullet Test

Source/Internet Screenshot from New Energy Outlook

Through these seemingly outrageous yet meticulously conducted tests, automakers showcase the true capabilities of their products. Whether facing rollovers, low temperatures, high-altitude drops, or more intense impacts, new energy vehicles consistently prove that safety is paramount. These extreme tests embody not only technical prowess but also a commitment to user safety, demonstrating automakers' responsibility and confidence in their products.

2. Making Safety and Reliability Visible

Consider the vehicle body structure. Imagine a car rolling down a 20-meter, 45-degree slope, simulating a vehicle's uncontrolled rolling during high-speed driving. Through actual collision and rollover processes, this test assesses the vehicle's durability and ability to protect occupants in an accident.

JIYUE 07's rollover test video reveals that despite rolling nine times down the slope, sustaining damage and shattered sunroof glass, its body structure performed admirably. Thanks to abundant high-strength steel and composite materials, akin to the car's muscles and bones, it combines rigidity with impact absorption. Notably, key components like the A-pillars, B-pillars, and roof beams remained sturdy during the rollover, exhibiting remarkable safety protection.

Photo/JIYUE 07 Rollover Test Car

Source/Internet Screenshot from New Energy Outlook

From the application of high-strength materials, energy-absorbing zone design, to the reliability of the airbag system, all aspects were thoroughly validated. Test results confirmed automakers' claims: exceeding five-star safety standards, exceptional body material composition, and nearly 40,000N·m/Deg torsional stiffness. With a roof capable of supporting 10.6 tons without deformation, seven space capsule-grade airbags, and innovative smart electric doors, it offers comprehensive occupant protection.

Smart electric doors are crucial for safety, ensuring they function under extreme conditions. In the rollover test, JIYUE 07's doors maintained structural integrity, free from deformation or jamming. Carefully designed door hinges and locking systems ensure smooth operation even in emergencies. Across frontal, side, and rear collision tests, its doors performed flawlessly, ensuring rapid evacuation routes.

Similarly, the freezing test at -18°C verified not just door functionality but also battery stability and safety in extreme cold. This breaks the stereotype of battery performance decline in winter, alleviating consumers' concerns about electric vehicle usage in cold regions.

In fact, batteries like CATL's Qilin used in JIYUE 07 also undergo rigorous testing before leaving the factory. After all, battery performance significantly influences new energy vehicle performance.

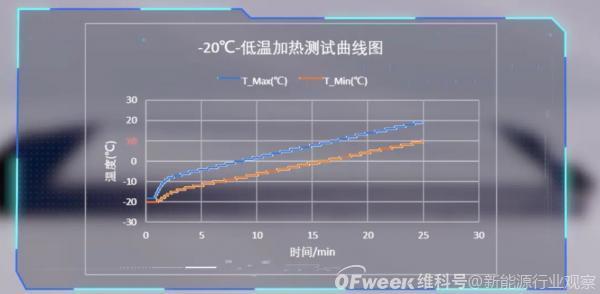

Batteries are placed in a dedicated low-temperature environment, typically set between -20°C and -30°C. During testing, they undergo multiple charge-discharge cycles, simulating real-world usage, to assess performance in extreme cold. Beyond low-temperature tests, batteries also undergo high-temperature, vibration, crush, needle-puncture, and cycle life tests. Battery manufacturers' testing rigor rivals that of automakers' extreme tests.

Photo/Qilin Battery -20°C Low-Temperature Heating Test

Source/Internet Screenshot from New Energy Outlook

After such stringent testing, the Qilin battery emerges triumphant: boasting 96.5% electric drive efficiency, a maximum power of 530kW, 0-100km/h acceleration in 3.5 seconds, a top speed of 230km/h, and a remarkable 12.4kWh/100km energy consumption (equivalent to just 3.7 yuan). Charging is equally impressive, with 600km range regained in just 10 minutes, eliminating range anxiety.

3. Empowering Safety with New Technologies

As one of the world's largest new energy vehicle markets, China leads not only in sales but also in technological innovation and safety guarantees. These extreme tests embody this trend, showcasing automakers' commitment to user safety and the importance of technology in empowering China's new energy vehicle industry.

Extreme tests drive automakers to develop new technologies, a testament to the empowering force of technological innovation.

Battery technology upgrades provide a stronger heart for electric vehicles; innovative body structure designs offer a sturdier armor; and smart safety systems like AEB, LKA, and ACC equip cars with intelligent eyes, enhancing driving peace of mind.

JIYUE 07, for instance, boasts Baidu's cutting-edge ASD Apollo Advanced Driver Assistance System, integrating L4-level autonomous driving capabilities into everyday life through "pure vision + end-to-end large model" technology.

Photo/ASD Apollo Advanced Driver Assistance System

Source/Internet Screenshot from New Energy Outlook

Imagine a car that not only brakes for you but also gently reminds you not to stray from your lane when distracted, even keeping an eye on blind spots – such a seamless driving experience!

Extreme tests are not just about vehicle safety; they also assess manufacturing processes and design standards. They help automakers identify and address potential design flaws and safety hazards, continually improving product quality to ensure every new energy vehicle leaving the factory boasts exceptional safety performance.

Extreme testing is not just for individual automakers but should be a collective pursuit across the industry. Through these tests, automakers learn from and compete with each other, driving technological advancements. This healthy competition elevates industry standards, propelling the new energy vehicle industry to new heights – a boon for consumers.

Each generation faces its own long march, and this aptly describes China's new energy vehicle industry. As history marches forward, China's mark is indelible on the banner of new energy vehicles. Both supply chain partners and automakers are part of this historic journey. Regardless of the future, China's pursuit of safety and excellence in new energy vehicles remains unwavering and boundless.