No stockpiling before the electric car launch, just for face-saving

![]() 11/12 2024

11/12 2024

![]() 607

607

Introduction

Introduction

Times have changed, and so must the game rules.

On November 7, Beijing time, the Xpeng P7+ was launched.

Frankly speaking, combining its starting price of 186,800 yuan and its product strength that is both sincere and streamlined, this B-segment pure electric sedan is poised to become another "hit" product. The fact that 31,528 orders were placed within 24 hours is the best evidence.

However, this article does not aim to analyze the market prospects of the Xpeng P7+ or discuss how high it can climb. Instead, I want to use its launch as an opportunity to present a thought-provoking photo.

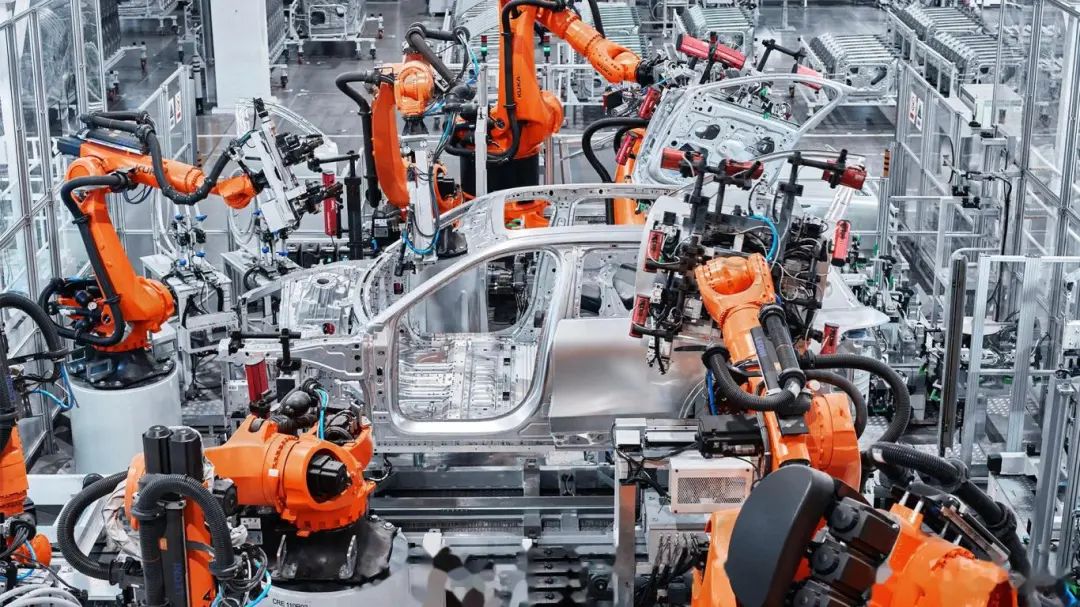

From the content, we can see the densely packed Xpeng P7+ vehicles, in various colors, neatly arranged on the open ground of Xpeng's Guangzhou factory. Accompanied by the setting sun, they exude a sense of oppression for some reason.

In contrast, what strikes me more is the ambition of the Xpeng P7+ to achieve "delivery upon launch, and immediate high volume."

These ten words are easy to say but difficult to implement.

As a media outlet, I have witnessed too many new energy vehicles with decent specifications and configurations ultimately end up with mediocre results due to poor manufacturing capabilities. As for who these vehicles are, feel free to identify them yourselves.

Past experience tells us that "opportunities are fleeting. If you cannot seize the first-mover advantage, you will be caught in a tug-of-war with latecomers."

As mentioned in previous articles, "whether the product is powerful determines the lower limit of sales. Correspondingly, whether production capacity is powerful determines the upper limit of sales."

In the dazzling Chinese automotive market where new products emerge in an endless stream, consumers' patience for selecting new energy vehicles generally does not exceed about 8 weeks or even less.

In other words, they are willing to wait for a maximum of two months.

For all automakers, unless you have a very impressive brand appeal that makes people willing to wait without complaint or offer compensation policies that are so sincere that people cannot refuse, you will face the situation of "having the duck cooked but letting it fly away" due to manufacturing constraints.

Any deviation or mistake in the delivery process will prompt many eager competitors to rush in and grab a share of the pie. Order poaching among competitors is common, and business competition, though unsophisticated, is ruthless.

To put it bluntly, "if your production capacity sucks, you deserve to get beaten up.""

Given this background, the solution to the dilemma must be multidimensional. For example, collaborate with core suppliers in advance to prepare for future expansion; the boss must not be absent-minded and must have a thorough understanding of the overall situation on the manufacturing side; sufficient pressure must be exerted on the direct person in charge, and it is not excessive to issue a "military order"…

Rationally and objectively speaking, each of these aspects must be achieved. Only then will the slogan "delivery upon launch, and immediate high volume" not remain merely a self-indulgent claim. Of course, there is another point that is often overlooked – the importance of "stockpiling".

The photo of the Xpeng P7+ at the beginning of the article already serves as good evidence.

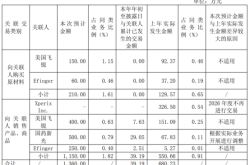

Take Xiaomi's SU7, an absolute top seller in China's automotive market this year that surpassed the 20,000-unit mark in October, as another example. A significant reason why it was able to deliver over 10,000 units within just 32 days of its launch is due to the several thousand "founder's edition" vehicles produced in advance.

Once released, these vehicles could be continuously delivered to eager car owners. On the one hand, it made a resounding start in grabbing market share; on the other hand, it also bought valuable time for its manufacturing side to ramp up production.

In contrast, the ZEEKR 007X, despite facing siege pressure from competitors such as the Tesla Model Y, LeTao L60, IM Motor's R7, AITO's M7, and IM Auto's new IM 7, has still delivered 17,000 new vehicles to customers within 40 days, according to official data.

Yes, you read that right, it's that impressive.

Faced with these results, on the one hand, we must commend this new force in automaking, backed by Geely, for its production ramp-up capabilities. On the other hand, we should also learn from its wise decision to stockpile vehicles.

While other players in the midsize SUV segment were still between launch and delivery, the ZEEKR 007X had already begun harvesting sales crazily.

Similarly, the recent launches of the Xingyuan and Yinhe E5, both pure electric compact cars under Geely, have also benefited from similar approaches.

This reminds me of Li Bin's controversial statement during an exclusive interview the day after LeTao's L60 entered the market on September 20, Beijing time.

"There is no company in the world that can produce 10,000 units of a new car in the first month. This does not conform to the objective laws of the industry, unless you stockpile a batch of cars there. We don't want to do such things.""

In retrospect, this statement seems quite ironic, especially when it is known that LeTao's L60 delivered only 4,319 units in the entire month of October, leaving a mixed feeling.

Even according to Li Bin's current plan and pace for manufacturing this product: "Our expectation is to reach 5,000 units in October, 10,000 units in December, at least 16,000 units in January next year, and climb to 20,000 units in March next year.""

At first glance, this doesn't seem too bad.

But the question is, why not stockpile vehicles to improve LeTao L60's situation when it's instinctive to do so? In China's automotive market this year, every automaker is fighting for a share in a jungle full of thorns. Continuing to be passive and slow will only lead to harsh lessons.

Unfortunately, it's too late to say anything now. Choosing to save face but suffer in silence has led to this situation. Next, we hope that the manufacturing side will not let us down again.

Zooming out, as the wave of electrification accelerates, many previously followed rules are being overturned. In the era of traditional fuel vehicles, each step from preheating, unveiling, pre-sale, launch, to delivery of a new product was carried out step-by-step.

But in the era of smart electric vehicles, the brutality of competition far exceeds imagination. Therefore, many processes are being compressed and integrated, emphasizing extreme efficiency. "Stockpiling" is one of the strategies derived from this.

This requires that when a new product with hit potential just enters the preheating stage, the corresponding factory should already be operating at full capacity to speed up production. By the time of launch, the brand should already have thousands of "trumps" in hand, and the entire supply chain should have been polished and ready for rapid production ramp-up.

Such an approach serves multiple purposes and has gradually become a necessary action for everyone…

Car enthusiast,

and a fan of electric vehicles~

THE END

Scan the QR code | Follow us

WeChat ID | iAUTO2010

Recommended Reading

Three Paths for Foreign Automakers | CIIE, the Way Out

Voyah "Halts Sailing," Who's Next?

If Trump Takes Office, Can Chinese Automakers Open Factories in the US?