Debating between oil vehicles and electric vehicles? Half of new vehicles are "released with defects"

![]() 11/19 2024

11/19 2024

![]() 677

677

Introduction

Introduction

Is the quality of oil vehicles better than that of electric vehicles? The truth is beyond imagination…

Before you scroll down, let's consider two questions together with me:

What are the reasons behind the general perception that the quality of new energy vehicles (NEVs) is inferior to that of internal combustion engine vehicles (ICEVs)?

Why is the quality of NEVs getting worse?

NEVs have a shorter development history than ICEVs; they prioritize marketing over product quality; the supply chain can't keep up…

If you agree with these answers, it means you have considered these issues.

If you secretly disagree and wonder, 'Where did this irresponsible editor come from, boldly claiming that the quality of NEVs is inferior to that of ICEVs and getting worse? What are they trying to achieve here?'

Then you're either a rationalist with a dialectical mindset, not easily misled by leading questions, or most likely an NEV owner who feels unjustly treated for their beloved car.

With that said, the question naturally changes.

Which type of vehicle has better quality: NEVs or ICEVs?

Has the quality of NEVs and ICEVs deteriorated?

Unfortunately, even after extensive research, I haven't found answers to these two questions. Since that's the case, let's start a debate, presenting arguments and viewpoints from both sides, and leaving it to the readers to decide.

If you have an answer or want to add arguments, feel free to engage in polite discussions in the comments section.

Pro: ICEVs are more reliable

Based on life experience, ICEVs have a longer history, a well-established supply chain, and time-tested products, so their quality should be better. Not to mention that NEVs have a shorter development history, an imperfect supply chain, and frequent issues like black screens on the center console, spontaneous battery combustion, and loss of vehicle control.

If experience is too subjective, we also have objective data.

Based on data from nearly 100,000 car buyers or renters in 2024, the 2024 Initial Quality Study (IQS) by J.D. Power shows that ICEVs have an average of 180 problems per 100 vehicles, while pure electric vehicles have as many as 266 problems, 86 more than ICEVs.

According to the data, both electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs) have more problems than ICEVs. Frank Hanley, Senior Director of J.D. Power's Automotive Benchmarking, noted in the report that 'due to more severe issues, EV and PHEV owners have a repair rate three times that of ICEV owners.'

Quality issues with NEVs are not just concentrated in new vehicles. Even after the break-in period and entering the optimal usage period, NEVs still have more quality issues.

Based on an extensive survey of 30,595 vehicle owners in the US (with vehicles aged 3 years), the 2024 U.S. Vehicle Dependability Study shows that the average PP100 index for ICEVs is 187, 191 for hybrids, 216 for PHEVs, and 256 for EVs.

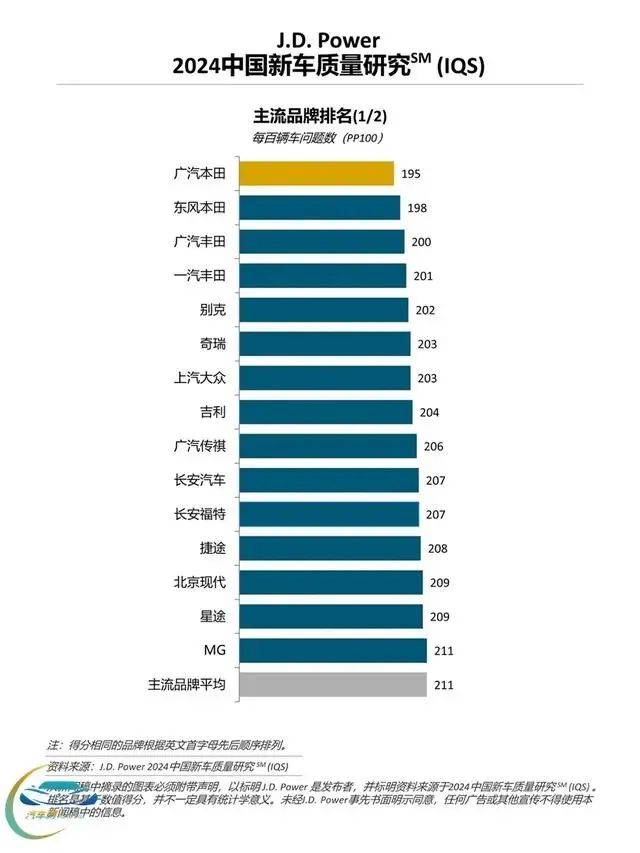

'Can the foreign market be compared to the domestic market? What's the point of using foreign data?' To be more persuasive, let's focus on the domestic market.

Although the authority of J.D. Power's research in China is questioned due to its intricate connections with various automakers, the report still has some reference value given its years of experience in the industry.

In June, J.D. Power China released the 2024 China New Energy Vehicle Initial Quality Study (NEV-IQS), which measures quality issues encountered by new NEV owners within 2 to 6 months of ownership.

The results show that new NEVs have a similar number of quality issues as ICEVs but have seen a significant increase compared to last year, raising concerns.

The data shows that the industry-wide average number of quality issues in 2024 was 210 PP100, a sharp increase of 37 PP100 from 2023, and the growth rate of quality issues accelerated compared to 2023 (+21 PP100).

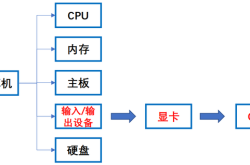

In September, the 2024 China Initial Quality Study (IQS) for ICEVs revealed that the number of quality issues per 100 new ICEVs increased by 8 PP100 from 2023 to 212 PP100.

Although the domestic survey indicates that NEVs have a slight advantage over ICEVs with 2 fewer PP100, their rapid growth trend is concerning. If this continues, the number of quality issues in new NEVs may exceed that of ICEVs by 2025.

Since J.D. Power China only has quality reports for the initial usage period of NEVs, a comparison of longer-term quality issues is currently unavailable.

Moreover, both domestic and international J.D. Power studies point out that the number of quality issues has increased year-over-year for both new and broken-in vehicles, regardless of whether they are NEVs or ICEVs. In other words, vehicle reliability is declining.

Based on the above data, it seems that the quality of NEVs lags significantly behind that of ICEVs. But is that really the case? Let's hear the counterargument.

Con: NEVs are superior

Although NEVs initially had frequent quality issues, many of these issues have been resolved with technological advancements.

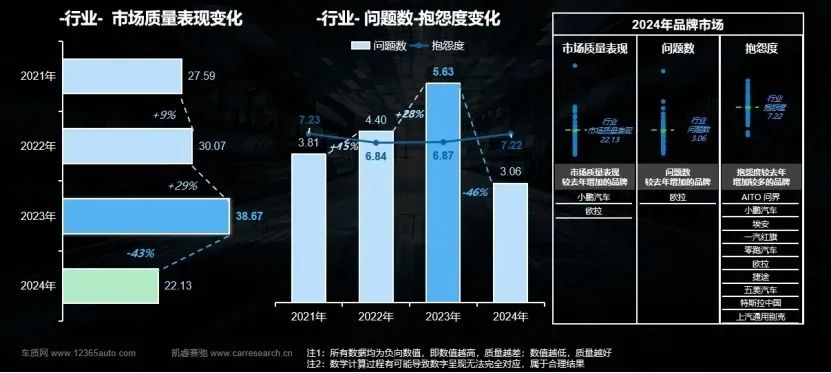

In September, the 2024 China Automotive Product Quality Performance Study (AQR) was jointly released by Autohome and CRI Consulting.

The AQR project uses market quality performance to represent respondents' perceptions of all vehicle quality issues (Market Quality Performance = Number of Issues x Degree of Complaint; the data is a negative value, with lower values indicating better quality).

The 2024 study covers 51 mainstream automotive brands, with domestic brands accounting for 56.9% of the sample. It also includes 128 models across 22 market segments, of which 46 are NEVs, accounting for 35.9%.

Contrary to the conclusions of the J.D. Power study, the AQR results show a 43% decrease in the market quality performance value compared to the previous year, ending a three-year upward trend. Both ICEVs and NEVs have improved in quality.

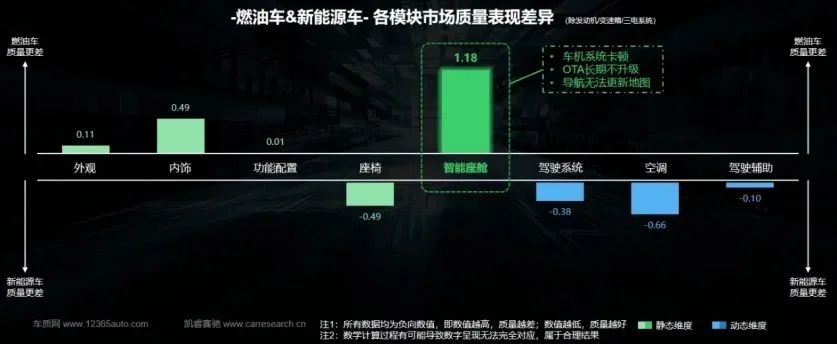

Regarding the quality comparison between ICEVs and NEVs, the results are diametrically opposed. The AQR results indicate that NEVs perform better overall, especially in the intelligent cockpit module, with superior exterior, interior, and functional configurations compared to ICEVs.

However, it's important to note that the market quality performance relied upon in this report depends on the number of issues and the degree of complaint, giving NEVs a natural advantage.

According to data released by the Ministry of Public Security, as of the end of June 2024, China had 440 million motor vehicles, including 345 million ICEVs and 24.72 million NEVs. The much larger number of ICEVs inevitably leads to more complaints, causing deviations from the actual situation.

Moreover, discussing vehicles in general terms without considering specific models is somewhat misleading.

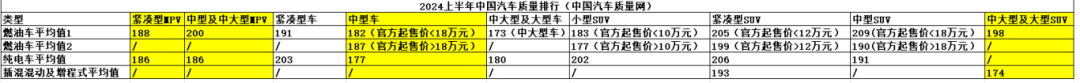

Therefore, it's necessary to introduce a third ranking: the China Car Quality Network's 2024 First Half-Year China Car Quality Rankings. This ranking evaluates vehicle quality using averages, eliminating the potential influence of the large number of ICEVs.

The 2024 First Half-Year China Car Quality Rankings assess models that have been on the market for at least six months (excluding imported models), using a comprehensive evaluation of complaints, defect risks, reliability, safety, and environmental friendliness. The lower the score, the better the quality.

After summarizing the data, I found that NEVs perform better in compact MPVs, mid-size and large MPVs, and mid-size and large SUVs, while they lag behind ICEVs in compact cars and small SUVs.

Design defects are a common problem

Although there is still no consensus on whether ICEVs or NEVs have better quality, a common trend emerges from the above reports: the number and proportion of design defect issues in vehicles are increasing.

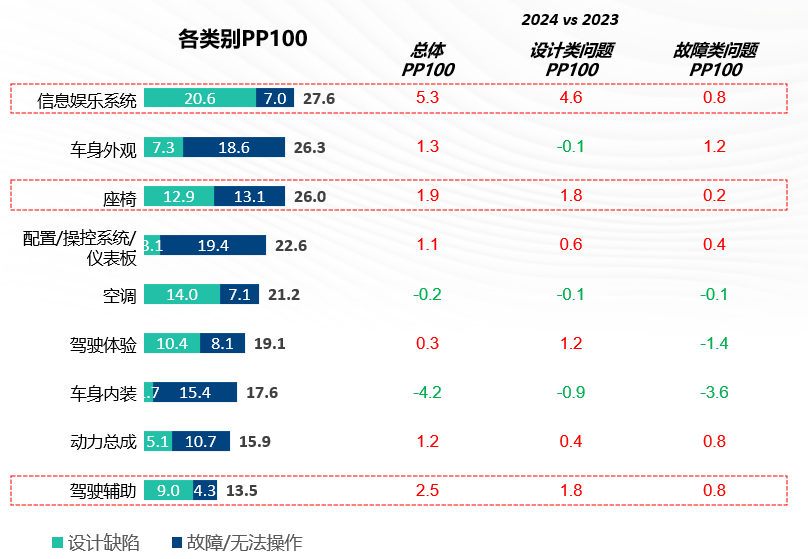

In J.D. Power's reliability studies, vehicle quality issues are categorized as failures and design defects. Failures refer to issues that affect normal functionality after a malfunction occurs, while design defects are the responsibility of the OEM. Due to design defects, user inconvenience has been persistent from NEVs to ICEVs.

The overall number of quality issues in the domestic NEV industry surged by a terrifying 37 PP100 this year. More alarmingly, 35 of these 37 additional PP100 were due to design defects, a significant blow.

ICEVs fared even worse. In this year's ICEV reliability study, although failures remained the primary source of complaints, they decreased by 1 PP100 compared to 2023, indicating improved quality.

However, design defects overshadowed this improvement, increasing the PP100 by 9.1 points, leading to an overall decline in ICEV reliability. Among the most complained-about issues in the infotainment system, the top five issues were all design defects, including insensitive touchscreen controls, Bluetooth pairing/connection issues, frequent inability of the built-in voice assistant to recognize commands, car Wi-Fi pairing/connection problems, and inaccurate in-car navigation systems.

Meanwhile, the total number of design defect issues in ICEVs also reached 84 PP100, almost equal to failure issues. In other words, an average of 86 issues per 100 ICEVs are caused by inherent design defects.

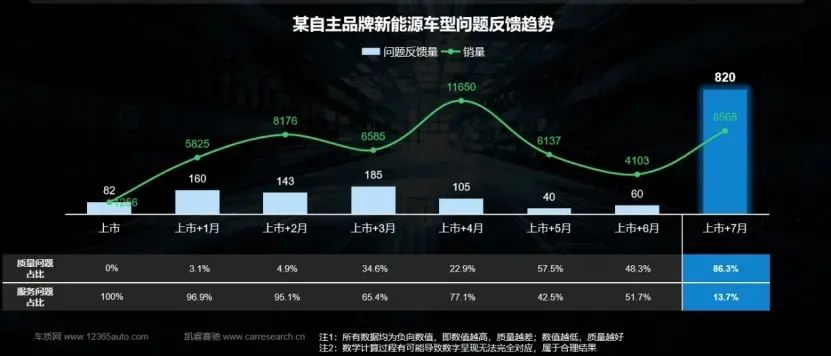

The phenomenon of new models being 'released with defects' is also reflected in the AQR: nearly half of all industry-first quality issues occur within the first month, with 51% for domestic brands and 48% for multinational brands.

The study shows that the primary issues with ICEVs focus on engine malfunction lights, laggy infotainment systems, and system crashes, while those with NEVs center around system crashes and lags. Both types of vehicles share the common issues of system lags and crashes, which can be classified as design defects.

Whether you believe ICEVs are of better quality (pro), insist that NEVs are more reliable (con), or you're the author currently writing this, our ultimate goal in gathering here to share our opinions is not to criticize or compete but to identify problems, offer suggestions, and promote the development of the automotive industry.

With that in mind, I'd like to propose a few questions for further discussion: Why are there so many design defects, and why are they increasing? How can we reduce design defects and be responsible to consumers?

Regarding the first question, Yang Tao, General Manager of J.D. Power China's Automotive Product Business Unit, has pointed out that the pace of new vehicle launches in the Chinese market is accelerating, shortening the development cycle.

AQR believes that the industry-wide price war in 2024 has shifted users' focus to price, reducing their demands for certain products and sensitivity to issues.

The shortened development cycle for new vehicles and intense price competition, which compresses R&D, component, and testing costs, are indeed the main reasons for vehicle design defects. However, when these design issues transfer from the OEM to consumers, who have to bear the cost, it's difficult for anyone to accept.

Technology is constantly evolving, and design defects are inevitable. However, we should not ignore them and allow them to grow unchecked.

After the price war, quality competition is inevitable. In this context, the question of 'how to reduce design defects and be responsible to consumers' must be answered by automakers through their actions. The one who gives a more satisfying answer will undoubtedly win the hearts and minds of consumers.

Maintaining high product reliability and durability while ensuring the speed of new vehicle launches and reasonable pricing will be a key challenge that automakers need to balance in the future.