50,000 jobs at risk, Europe's auto industry struggling to survive the winter

![]() 11/29 2024

11/29 2024

![]() 633

633

Introduction

Introduction

European automakers are well aware that the industry needs a radical reform. To escape passivity, mere "Band-Aid" measures are insufficient.

The German model, no longer a myth.

On one hand, Germany's vaunted automotive manufacturing industry has continued to weaken, with the deterioration of economic prospects dragging down profits and sales in the automotive supply chain. On the other hand, after the Russia-Ukraine conflict, Germany lost the cheap advantage of Russian natural gas, and soaring energy prices have further impacted the core position of automobile manufacturing.

More importantly, as the center of European commerce and manufacturing, Germany is currently facing a new pressure. Donald Trump, who is set to return to the White House, may bring unprecedented trade tariff strikes to the country, and supply chain security is also a significant challenge.

The plight of Germany's automotive industry is a microcosm of the gradual collapse of European automotive manufacturing. As of 2023, the economic contribution of the automotive industry accounted for 17% of Germany's exports, and the number of people employed in automobile-related industries has exceeded 750,000.

Since last year, more and more German manufacturers have begun to cut costs, with news of layoffs and pay cuts frequently appearing in the media. As more German factories close, "Made in Germany" is creating new shockwaves globally and impacting other core markets.

As the birthplace of the world's automotive industry, Germany is currently facing an unprecedented crisis. Even Volkswagen, which the country has always been proud of, and the giant auto parts company Bosch Group, are caught in a whirlwind of public opinion due to factory closures and layoffs.

Volkswagen is well aware that the company needs a radical reform. To escape passivity, mere "Band-Aid" measures are insufficient. Company executives have bluntly stated that Volkswagen's labor costs are currently nearly twice those of other European automakers, and layoffs and other measures are unavoidable if the planned 4 billion euros in cost reductions are to be achieved.

Germany's automotive industry stalls

Germany has long been regarded as Europe's most dynamic business engine, fueled by the prosperity of its automotive manufacturing industry. As prosperity fades and challenges mount, this engine is gradually becoming fragile, and the old model must be adjusted as soon as possible before facing greater economic challenges.

Under the old system, the automotive industry faces challenges head-on.

First, supply chain disruptions. Taking German manufacturing as an example, German parts are an indispensable part of assembling cars in the United States. Once the production process in North American factories slows down or production adjustments are made due to domestic substitutions in the Chinese market, the German supply chain will also be affected.

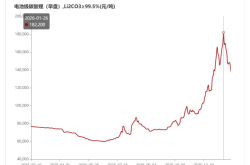

Second, rising costs. The lack of competitiveness in key components such as batteries and chips, coupled with generally higher energy, labor, and raw material costs than in China, makes it difficult for European automobiles to stand out in terms of cost. If the supply of core components tightens, it will inevitably push up dealer and end-user prices.

Third, investment shifts. As prices rise, demand for German cars in North America and other regions will decline, prompting consumers to turn to local brands like Tesla or Japanese and Korean brands. In the long run, global investment may shift from Germany to places like the United States and China, a change that will come at the expense of Germany's industrial dominance.

Germany's predicament is a warning sign that the old system is heavily reliant on traditional industries. The global economy is undergoing tremendous changes, with the transition to clean energy and geopolitical instability reshaping global production and consumption patterns. When the fundamental logic of a specific business or economic model changes, market leaders must adapt, adjust, and make changes.

Currently, the automotive industry throughout the European Union is at a crossroads: green transformation, digitization, and global competition. In particular, the rise of China as a leading global automobile exporter has fundamentally changed the competitive landscape.

Recent cost-cutting measures by German automakers, ranging from supply chains to OEMs, are sending a signal that the EU's automotive industry must quickly adapt to new business models to mitigate the risks posed by these disruptive trends.

Currently, the EU's automotive industry directly and indirectly employs 13.8 million people, accounting for 6.1% of total EU employment. In addition to Germany, countries such as Slovakia, Romania, Sweden, the Czech Republic, and Hungary still have automotive sectors that account for more than 10% of total manufacturing employment and possess vast upstream and downstream supply chain networks.

At the same time, changes in the supply chain have altered the operating foundation and competitive landscape of the automotive industry, catalyzing the largest structural transformation in the history of the automotive sector. New companies from the battery and chip sectors are becoming increasingly powerful, surpassing many traditional parts suppliers in terms of profit returns and business prospects.

More than a decade ago, European manufacturers, including Volkswagen and BMW, began selling electric vehicles. However, these German companies missed the opportunity to control battery costs. In contrast, Chinese competitors dominate the production of electric vehicle raw materials and core components (batteries, chips) and can sell cars at very low prices due to their excellent control over battery costs.

European automakers still face practical challenges with batteries. To turn a profit, costs must be controlled, but everyone is generally worried about battery costs.

China's automobile exports surpassed Japan in 2023 to become the world's largest. At this stage, China is the main source of automobile imports to the EU, with the total volume of automobiles imported from China to the EU increasing by nearly 40% from 2022 to 2023.

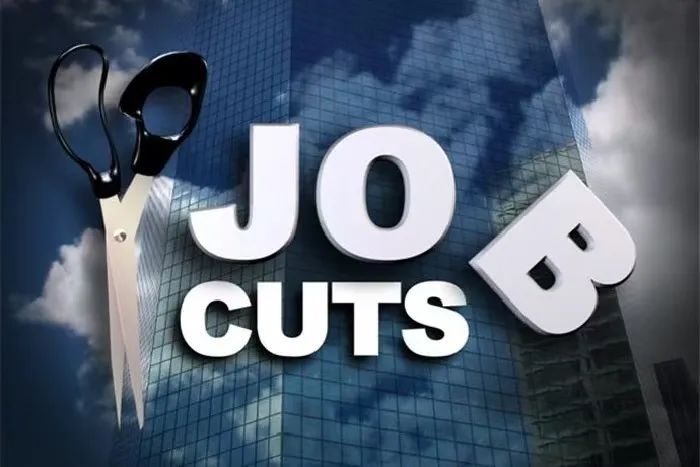

Layoffs affecting 50,000 people

Facing severe industry transformation and cost reduction pressures, European parts suppliers have successively initiated in-depth reforms and business adjustments over the past year, including plant closures, salary reductions, layoffs, and seeking independence for business units.

Spin-offs and reorganizations are exemplified by the transformation and upgrading of Continental, a European auto parts giant. According to German authorities, in the first half of this year, 20 automotive parts suppliers in Germany with annual revenues exceeding 10 million euros went bankrupt, a year-on-year increase of 60%.

This summer, Continental announced that it would spin off its automotive sub-group, with details of the spin-off and listing to be decided in the fourth quarter. After the automotive sub-group is spun off, the group will only comprise the tire and ContiTech sub-groups.

Within the group, management has been sharpening its knives, with thoughts of restructuring and transformation emerging as early as last year. In February this year, Continental planned to lay off 7,150 employees, accounting for 3.6% of its global workforce, and required this to be completed by the end of 2025.

During the golden age of fuel vehicles, these European and American parts giants were accustomed to "addition" and "multiplication." Tactically, they tended to "unite the vertical and horizontal" and let the big fish eat the small fish, integrating technologies and business segments. As long as the customer base remained, business would snowball.

Now, the golden age of fuel vehicles has become amber, and former advantages are likely to turn into liabilities. How to survive in the new industrial logic? It has been discovered that the previous "addition" and "multiplication" may not necessarily work, and it is necessary to learn to do "subtraction" and division for oneself, integrating and "cutting" different business segments simultaneously."

According to incomplete statistics from Auto Community, European automakers including Volkswagen, Ford, Mercedes-Benz, Audi, and BMW have all announced layoffs this year.

In September this year, Volkswagen announced the closure of three factories in Germany and decided to lay off tens of thousands of employees. Even if the remaining employees can keep their jobs, their wages will be reduced by 10%. Foreign media revealed that Volkswagen's latest wave of layoffs has had the greatest impact on the R&D department, with at least 6,000 of the 13,000 R&D personnel losing their jobs.

In the middle of this month, Ford officially announced layoffs in Europe. Due to the overall economic downturn, intensifying industry competition, and lower-than-expected sales of new energy vehicles, Ford will lay off 4,000 people in Europe by the end of 2027, with most of these positions in Germany, totaling about 2,900.

After announcing its third-quarter financial report data, Audi also announced job cuts, planning to eliminate positions outside of production to reduce labor force size and related costs. It is reported that Audi's layoffs in Europe will reduce the workforce by at least 15%, affecting 4,500 positions in Germany alone, making it one of the largest layoffs in the brand's history.

European auto parts giants are also having a tough time. According to incomplete statistics, including automakers and auto parts companies of various sizes, the cumulative number of layoffs officially announced by European companies currently stands at 50,000.

Bosch, undoubtedly the "giant" among global auto parts manufacturers, has topped the list of the top 100 automotive parts revenue for many years. Amid the wave of new Four Modernizations, the former "big brother" ranked first is also reshaping its new value chain in transformation.

Focusing on the transformation of the automotive industry, Bosch Group underwent its largest-ever reorganization and adjustment at the beginning of the year. As one of Germany's largest employers, Bosch also announced layoffs of about 5,500 employees this year, with up to 3,800 positions cut in Germany, and the working hours and corresponding salaries of other employees will be further reduced.

As early as two years ago, when the COVID-19 pandemic was at its peak, European automakers with a keen sense of smell had already anticipated the transformation risks at the crossroads.

For a long time in the past, the European automotive industry has benefited from five major advantages: technological leadership, cost efficiency, brand value, stable geopolitics, and incremental demand in the Chinese market. Currently, these five advantages are all under varying degrees of threat.

With the gradual decline of the five major advantages, European automakers at the crossroads cannot hide their anxiety. However, with the continuous onslaught of Chinese forces and the collapse of their own moats, all companies are well aware that they need a radical reform. Mere "Band-Aid" measures are insufficient. Layoffs and factory closures are just the tip of the iceberg of in-depth reform.