AVL Black Tech: Overcoming the 'Three-Body Problem' in Electric Vehicle Development with a 'Virtual Simulation Universe'

![]() 05/22 2025

05/22 2025

![]() 569

569

Introduction

Software bugs in electric vehicles (EVs) leading to global recalls often expose critical flaws in the development process—traditional testing methods are akin to 'validating a space shuttle with an abacus.' AVL's newly launched E/E integration solution transforms this landscape by establishing a digital twin full-scenario testing platform, boosting development efficiency by 300%. This article delves into this revolutionary technology.

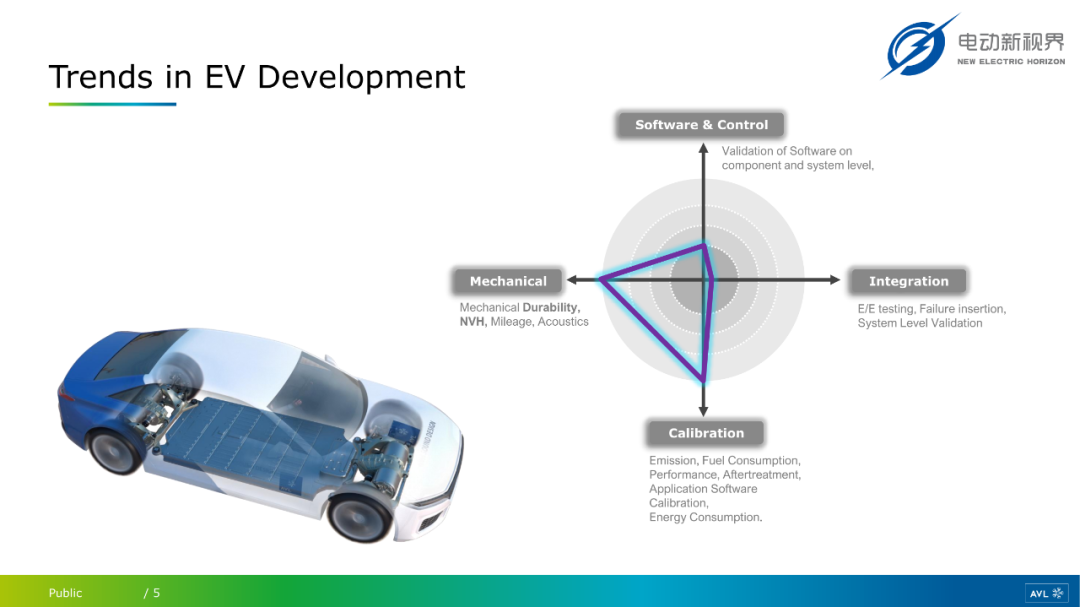

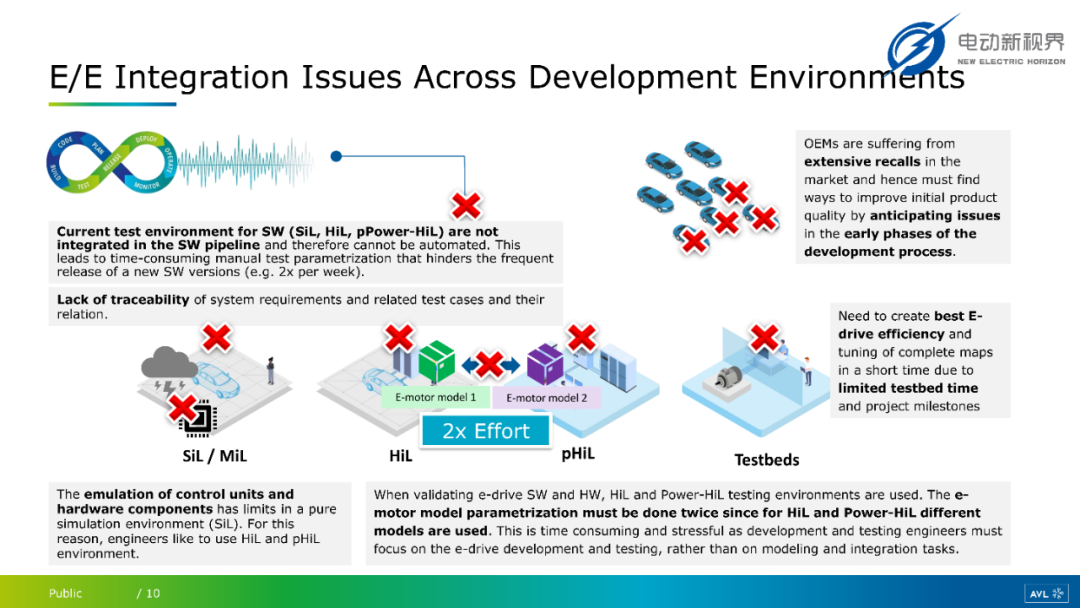

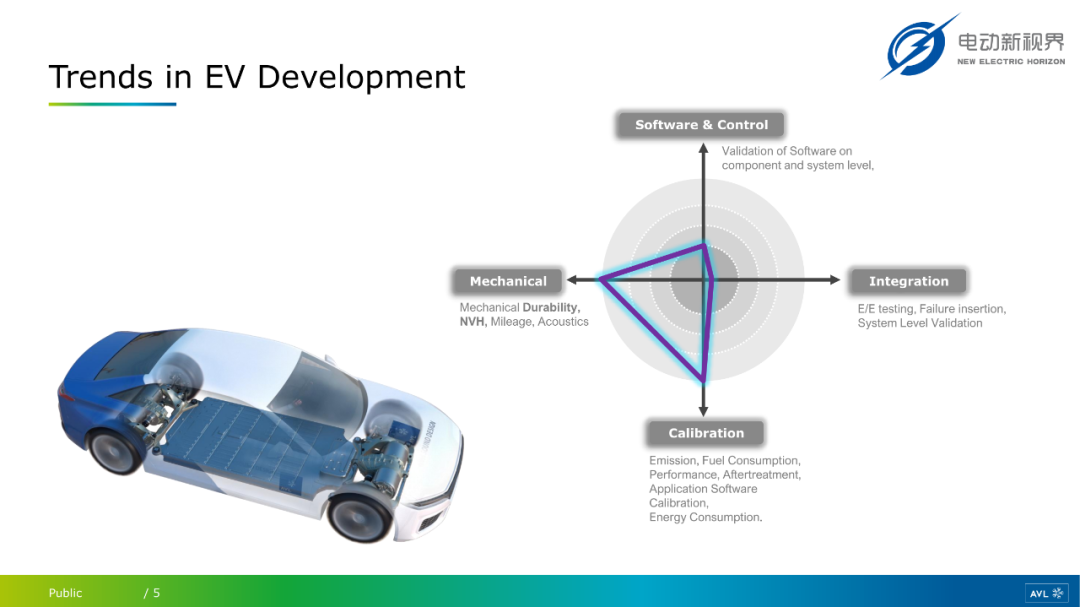

I. The 'Three-Body Dilemma' of Electric Vehicle Developers

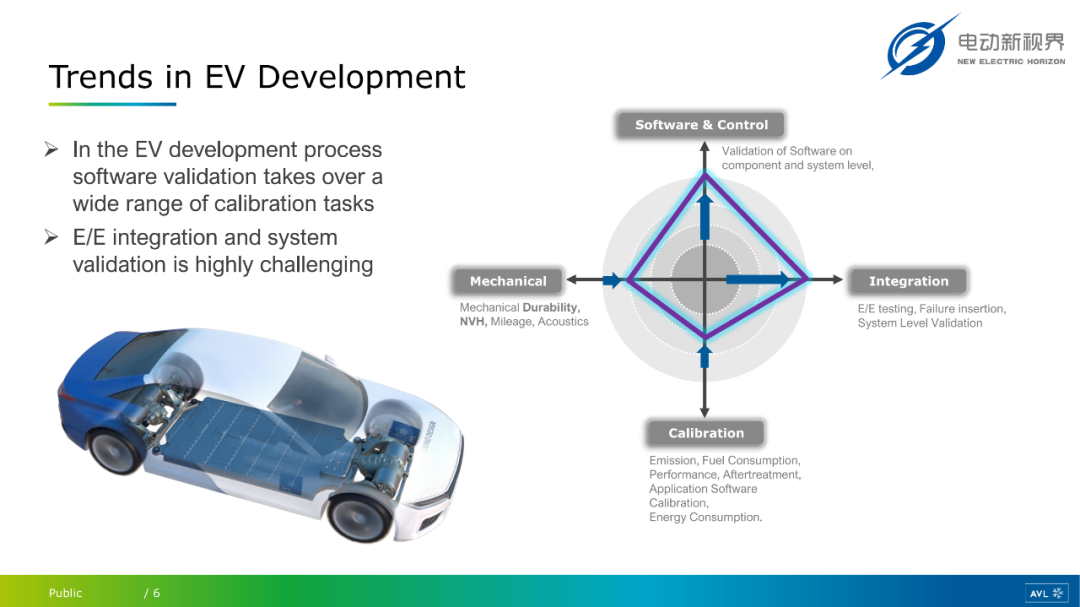

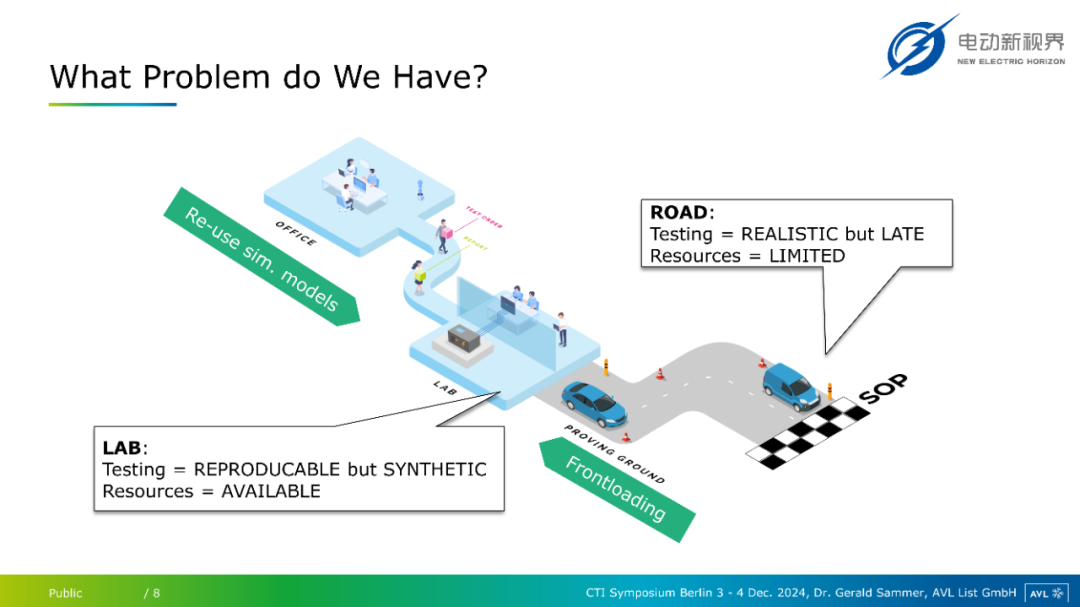

Traditional development processes face three parallel challenges:

- Laboratory testing: Repeatable but divorced from real-world vehicle environments

- Bench testing: Closer to reality but resource-constrained

- Road testing: Absolutely authentic but issues are often discovered too late

Data Comparison:

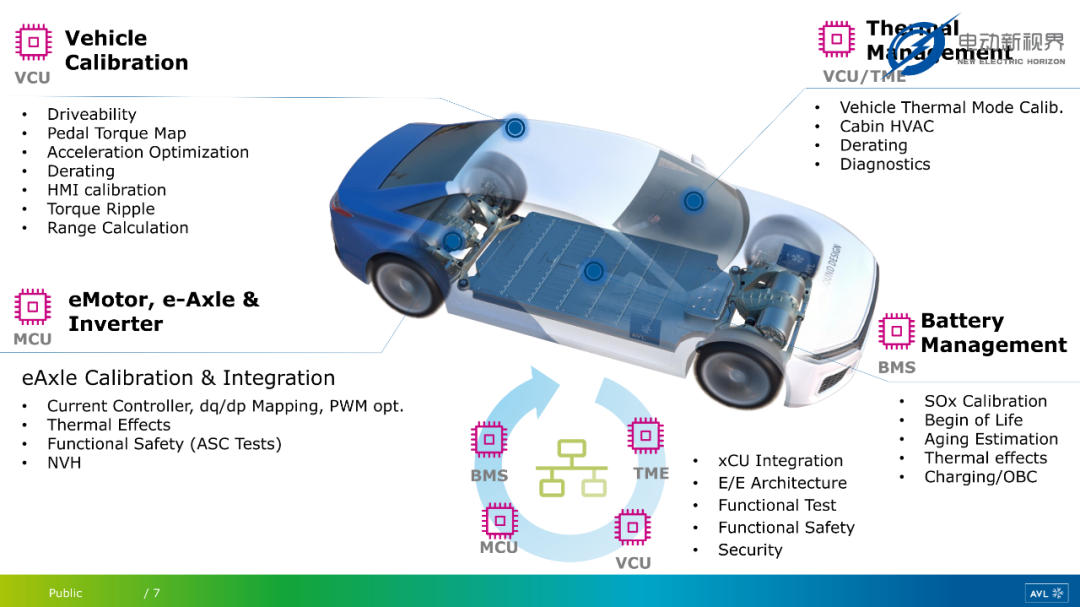

- Motor control parameter calibration demands over 200 hours of bench time

- Over 40% of EV recalls are linked to defects in electrical system integration

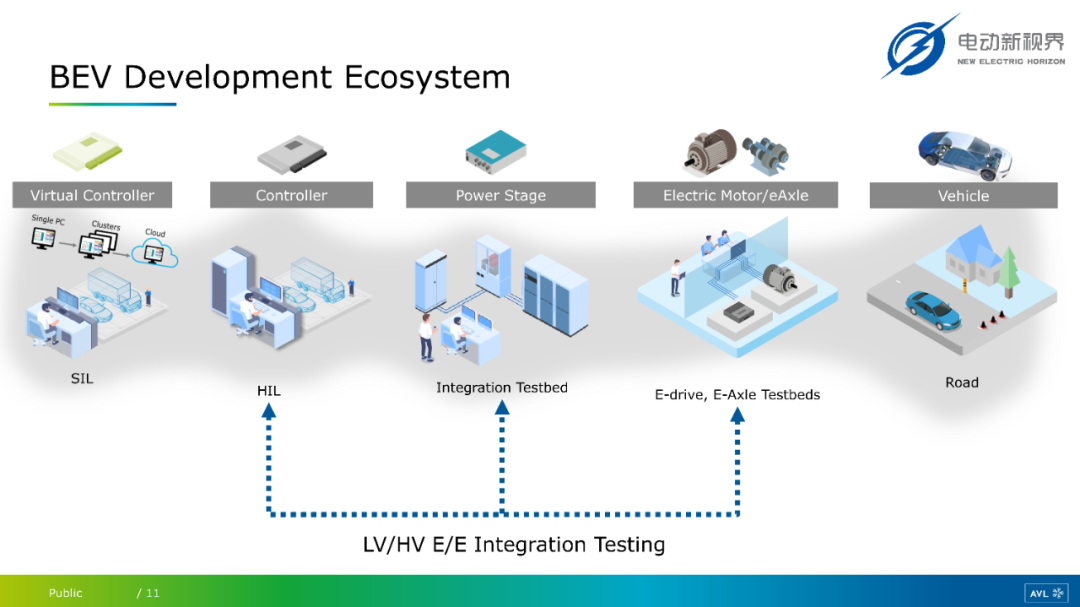

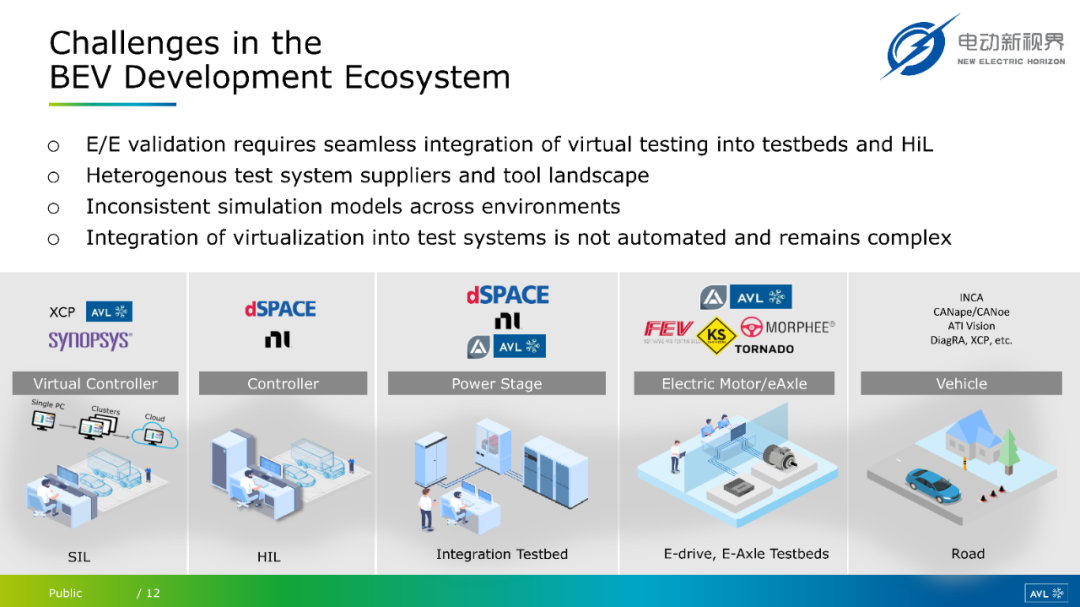

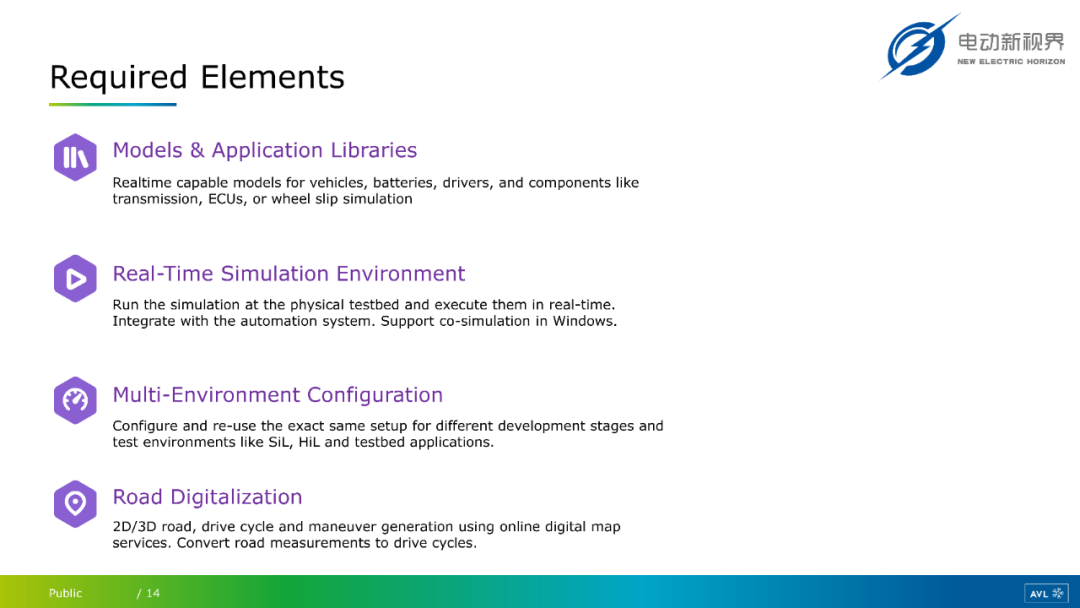

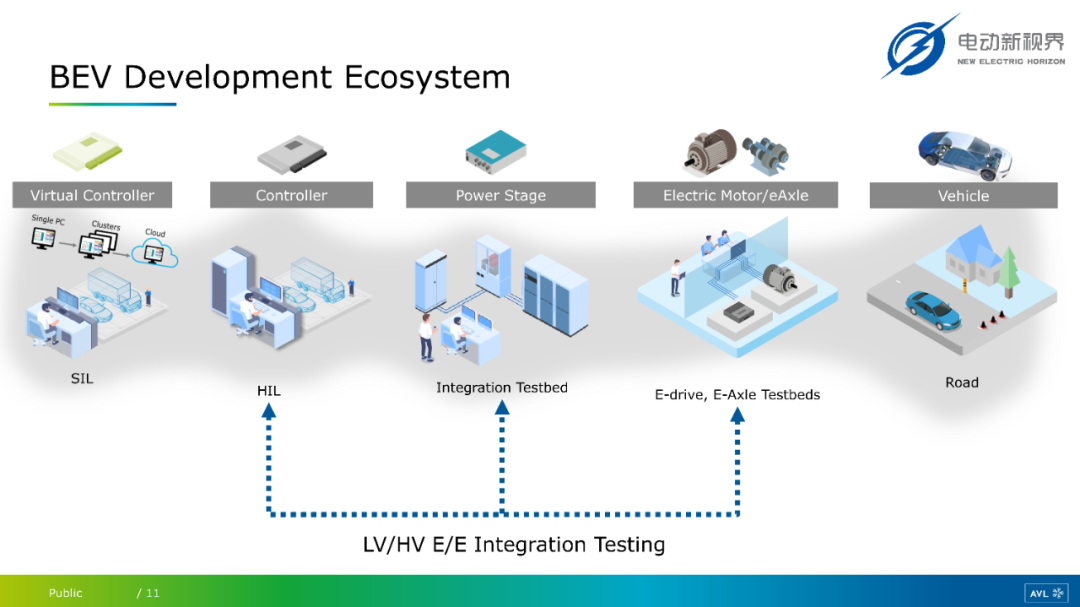

II. AVL's 'Virtual Planet' Architecture: The Core Four-Dimensional Space

- SIL (Software-in-the-Loop): A purely virtual environment for algorithm validation

- HIL (Hardware-in-the-Loop): Real ECU testing

- Power-HIL: Power-level hardware participation in simulations

- Road Digital Twin: 3D map generation for realistic road spectra

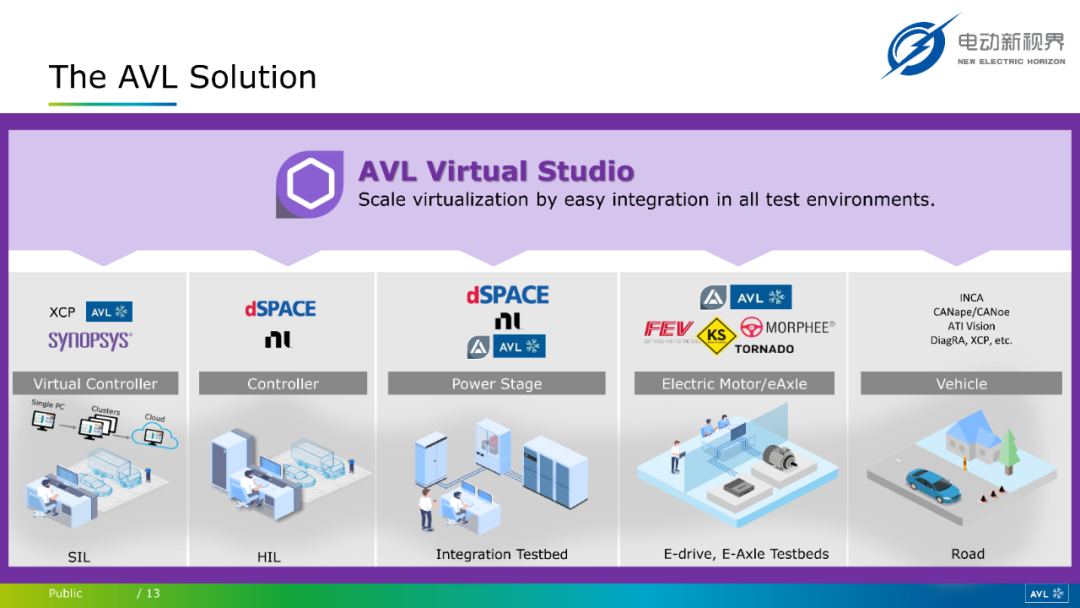

Revolutionary Breakthrough:

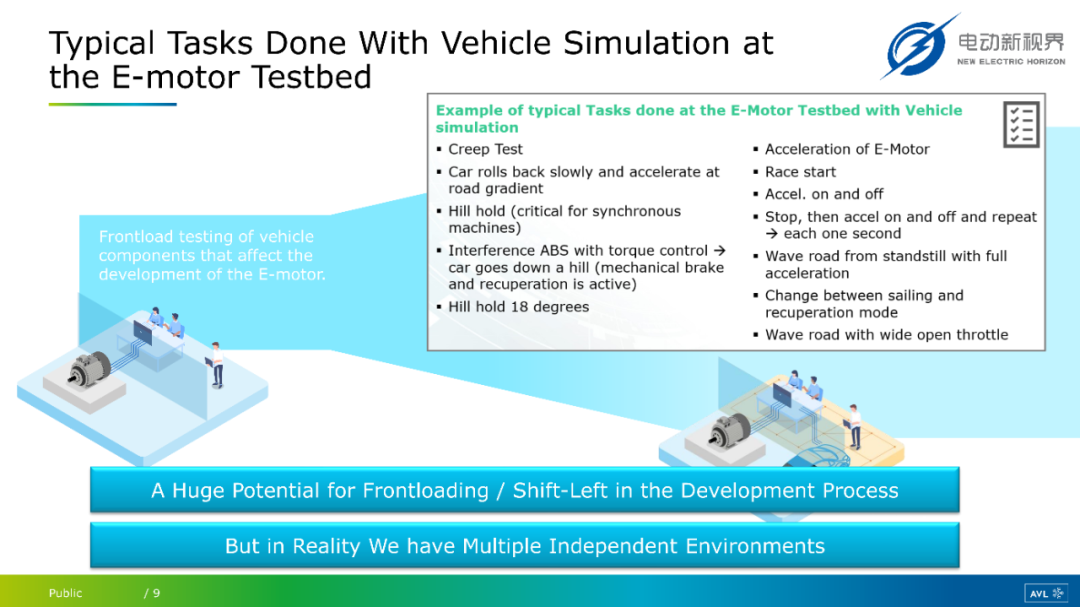

- Reusable motor model across all environments

- Automatic docking with toolchains such as INCA/CANape

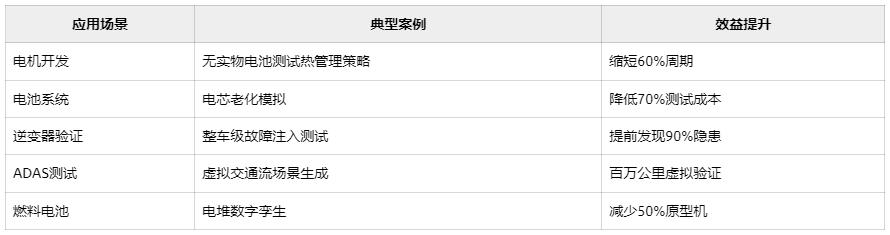

III. Five Key Applications

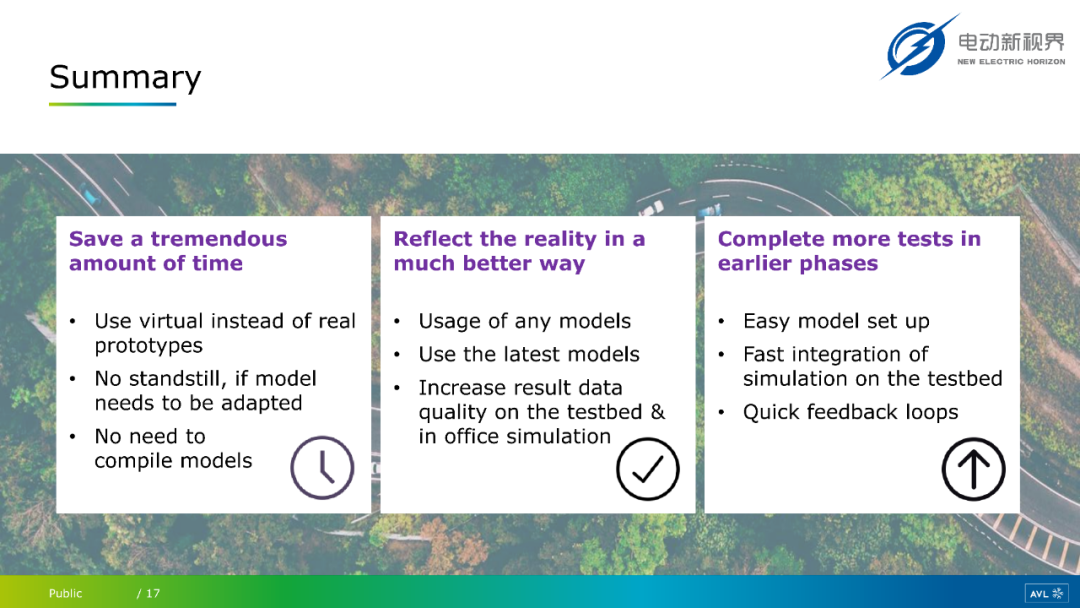

IV. A 'Time Machine' for Engineers

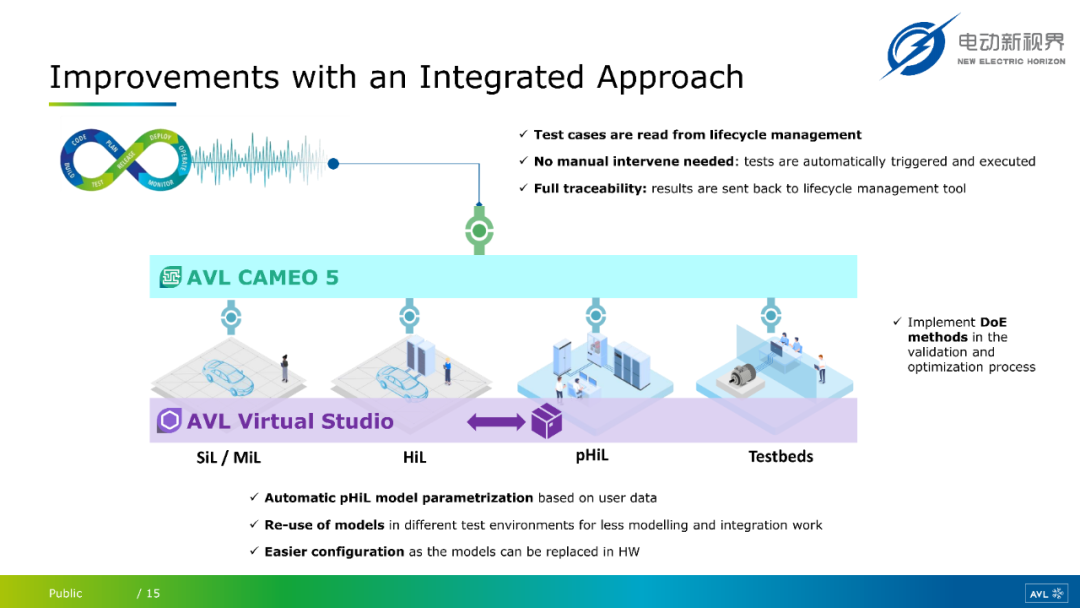

Powered by the AVL Virtual Studio platform:

- Requirement Traceability: Each test case automatically correlates with system requirements

- Intelligent DoE: Automatic optimization of parameter combinations (integrated with CAMEO 5)

- Digital Silhouette: Automatically executes 300 sets of regression tests at 3 AM

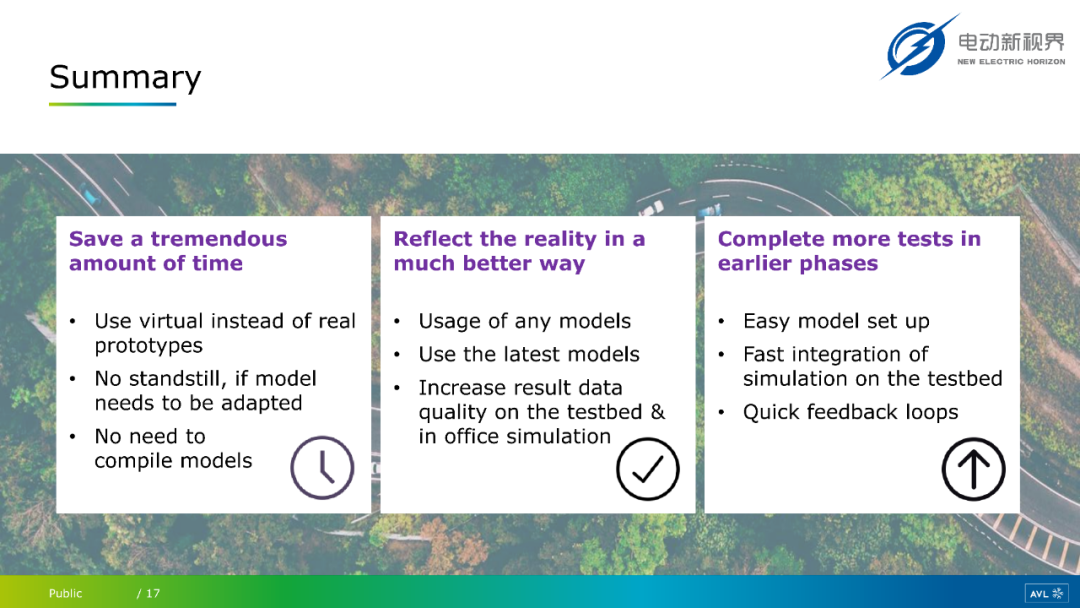

Customer Testimonials:

- A German luxury brand reduced the motor calibration cycle from 6 weeks to 10 days

- A Chinese battery manufacturer reduced fire tests by 80% through virtual thermal management testing

Conclusion

While the industry debates the merits of 'hardware-first, software-later' versus 'hardware-software synergy,' AVL has already redefined the EV development timeline with this solution. As Dr. Sammer, the speaker, eloquently put it, 'We don't sell simulation tools; we empower engineers to 'foresee the future.''