Understanding Hardware-in-the-Loop (HIL) in Autonomous Driving

![]() 08/14 2025

08/14 2025

![]() 483

483

In the realm of autonomous driving technology, Hardware-in-the-Loop (HIL) is a frequently mentioned term. But what exactly is HIL, and what role does it play in advancing autonomous driving? Let AI Driving Frontier guide you through this pivotal technology.

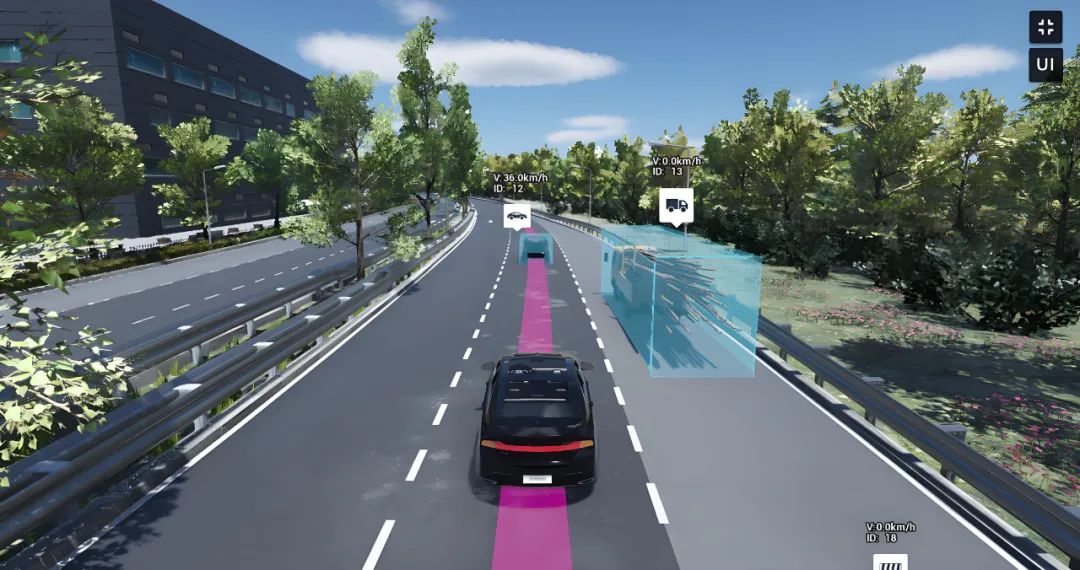

Hardware-in-the-Loop (HIL) is a crucial simulation technology used for testing and verifying complex systems. In autonomous driving, HIL sees widespread application. It involves connecting vehicle hardware components (such as control units, sensor modules, and brake actuators) to a simulation platform, where a computer-generated virtual environment drives these hardware components for real-time testing. Unlike pure software simulation, HIL combines real hardware with algorithms in a controlled environment, revealing potential issues earlier and more safely, thereby effectively reducing R&D costs, shortening development cycles, and enhancing system reliability and safety.

In the R&D process of autonomous driving, the separation of hardware and software testing typically progresses through three stages: Model-in-the-Loop (MIL), Software-in-the-Loop (SIL), and Hardware-in-the-Loop (HIL). The MIL stage primarily verifies the correctness of the control algorithm model, while the SIL stage allows the software version of the algorithm to run in a virtual environment and interact with simulation models. HIL, on the other hand, involves connecting the actual hardware control unit (ECU) to the simulation platform for joint debugging. For key subsystems in autonomous driving, such as environmental perception, safety decision-making, and execution control, HIL enables development teams to conduct extensive, long-duration, and high-intensity testing without the need for real-world vehicle testing, significantly improving testing efficiency and credibility.

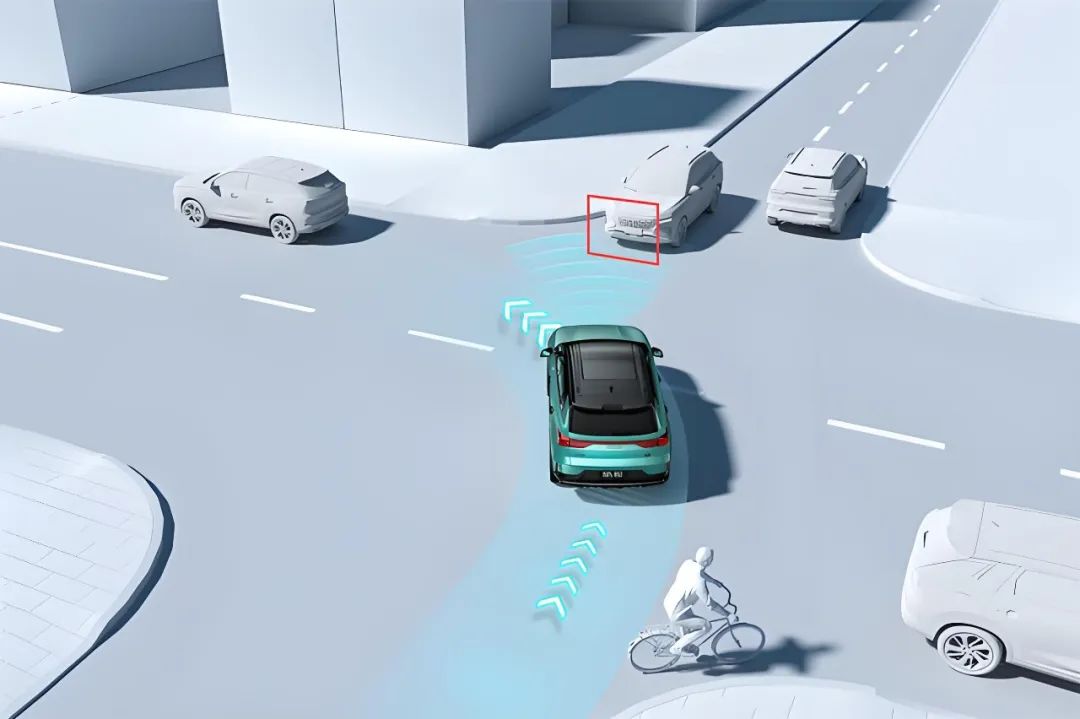

The core advantage of HIL lies in its ability to identify and rectify issues early in the integration of hardware and software. Traditional road testing often faces challenges like high costs, long durations, limited testing sites, and difficulties in reproducing extreme conditions. With HIL, researchers can simulate various complex scenarios, such as vehicle rollover during sharp turns, sensor signal attenuation in rainy or foggy weather, and emergency braking in response to pedestrians suddenly crossing the road. These scenarios, which are difficult or dangerous to replicate on real roads, can be precisely designed and repeatedly practiced through simulation software, aiding in algorithm tuning, hardware calibration, and fault diagnosis. Additionally, HIL platforms record vast amounts of operational data, providing detailed evidence for subsequent performance evaluation and safety verification.

The typical architecture of a HIL system includes a simulation host, a real-time simulator, interface boards, and the hardware unit under test. The simulation host runs high-level simulation models like vehicle dynamics, road environment, and traffic participant models. The real-time simulator converts these simulation signals into voltage, current, or digital signals that match the hardware interface, interacting with the control unit under test through high-speed data buses (such as CAN, Ethernet, FlexRay, etc.). Upon receiving simulation signals, the hardware unit generates control instructions based on its internal software program, which are then fed back to the simulation platform, forming a closed-loop real-time testing system. This approach enables testing not only the hardware's response under normal conditions but also its fault detection and fault tolerance capabilities through the injection of fault signals (like sensor disconnection or signal drift).

For autonomous driving systems, the perception module is particularly crucial. HIL testing helps teams verify the performance of multi-sensor fusion algorithms, including radar, LiDAR, and cameras, under various operating conditions. For instance, HIL can simulate the impact of headlight illumination on camera imaging during night driving or radar echo signal interference during multi-vehicle parallel driving. Developers can adjust environmental parameters such as raindrops, snowflakes, and haze on the simulation platform to generate more realistic perception data inputs and observe the algorithm's accuracy and real-time performance in detecting vehicles, pedestrians, and traffic signs, thereby adjusting filter parameters and optimizing fusion strategies.

At the decision-making and control level, HIL testing is equally vital. The autonomous driving decision-making unit needs to generate safe path planning and manipulation instructions based on perception results, which are then implemented through actuators for acceleration, deceleration, steering, braking, and other actions. By validating the control unit on the HIL platform, the R&D team can assess the stability and robustness of the control algorithm under different road conditions. For example, when simulating wet roads, the traction control system (TCS) and electronic stability program (ESP) of the control unit can effectively prevent vehicle sideslip. In overtaking or lane-changing scenarios, the control unit can respond quickly while maintaining a safe distance. These tests ensure that the autonomous driving system makes reasonable and safe control decisions in various extreme scenarios.

Undoubtedly, HIL testing significantly reduces the risks and costs associated with road testing. Real-vehicle road testing not only requires closed testing sites but also involves high expenses such as insurance, dedicated test personnel, and subsequent fault repairs. It is also constrained by road traffic regulations and climatic conditions, making it challenging to conduct extensive testing under all-weather and all-scenario conditions. In contrast, HIL testing can be conducted in a laboratory environment, allowing for the repeated execution of large-scale test cases at any time, greatly enhancing test coverage and efficiency. Furthermore, HIL platforms are highly automated, enabling batch testing and automatic generation of test reports, helping project teams quickly analyze and locate defects.

While HIL can effectively enhance simulation efficiency, it is not a perfect solution. As the simulation environment cannot fully replicate the real world, HIL testing may overlook some physical coupling effects or complex environmental interactions. For instance, subtle changes in tire-road friction, micro-vibrations of the vehicle body in strong winds, or even weak parasitic induction in hardware internal wiring may be difficult to replicate in simulation models. Additionally, building a high-precision HIL platform requires substantial human and material resources, including developing accurate vehicle and environment simulation models, procuring and customizing dedicated interface hardware, and maintaining the high availability of real-time simulators. Therefore, HIL is generally considered a crucial step after the purer SIL phase and before vehicle-in-the-loop (VIL) validation, with both working together to ensure the overall safety and reliability of autonomous driving systems.

With the evolution of autonomous driving technology, HIL testing has also advanced. For perception algorithms, more research teams are incorporating HIL testing based on data collected by real sensors, using pre-recorded real-vehicle environment data or simulation data to drive sensor inputs, further enhancing the realism of simulation data. In terms of control, automakers and Tier 1 suppliers are exploring hybrid HIL architectures that combine cloud-based high-performance computing with local real-time simulation to quickly deploy large-scale test cases and enable remote collaborative development. Furthermore, with the emergence of emerging technologies such as 5G communication, edge computing, and digital twins, future HIL platforms are expected to achieve higher distributed simulation capabilities, supporting the joint debugging and testing of multiple vehicles and road scenarios.

As an integral part of autonomous driving R&D, HIL plays a significant role in improving system safety, accelerating R&D progress, and reducing testing costs. It not only bridges the gap between pure software simulation and real-world road testing but also provides a robust guarantee for functional verification and performance optimization of autonomous driving systems through highly controllable and repeatable testing methods. Despite the challenges in accuracy, cost, and complexity, with the continuous advancement of simulation technology and hardware interfaces, HIL is poised to play an even more profound role in the field of autonomous driving, contributing to the advancement of intelligent transportation towards higher levels of safety and reliability.

-- END --