Shanghai-based Firm Emerges as a Super Hidden Champion: Annual Revenue of RMB 350 Million, Ranking Top Three Globally

![]() 01/16 2025

01/16 2025

![]() 628

628

Author: A Xin from Pencil Dao

Recently, JAKA Robotics, hailing from Minhang District in Shanghai, has submitted an application for listing on the STAR Market of the Shanghai Stock Exchange, sprinting towards an IPO.

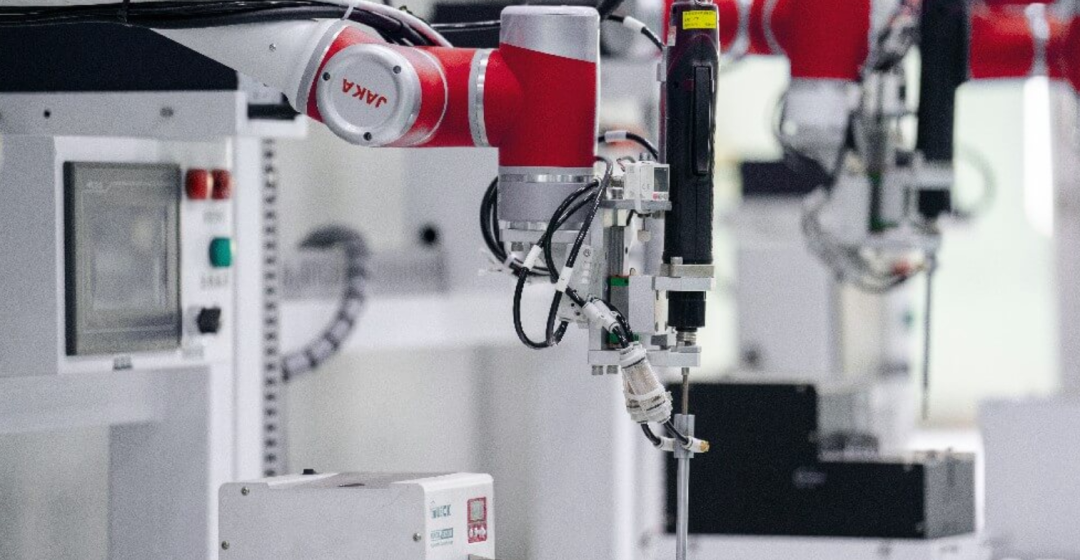

Specializing in the R&D, production, and sales of collaborative robots, JAKA Robotics offers robots that move flexibly like human arms, working alongside workers in the same workspace to complete various production tasks.

According to MIR Databank, in the global and domestic collaborative robot markets in 2023, JAKA Robotics ranked among the top three in sales, occupying a significant market position alongside renowned brands such as UR, Fanuc, AUBO, and Elite.

In the same year, JAKA Robotics sold 4,681 collaborative robots, capturing a global market share of approximately 8.2%, successfully positioning itself among the industry's top-tier enterprises.

So, what kind of remarkable company is this?

- 01-

Founded by Li Mingyang, a graduate of Shanghai Jiao Tong University, JAKA Robotics is based in Minhang District, Shanghai. Early in his career, Li Mingyang worked as an engineer at Shanghai Ziquan Beverage Industry Co., Ltd., where he accumulated substantial engineering experience.

He then joined Tetra Pak as a sales manager for seven years. During this period, while planning for Chinese dairy enterprises, he observed that while the milk processing stage had achieved a high level of automated production, gift box packaging required significant manual labor. Furthermore, as the market environment evolved, the age of workers packaging gift boxes increased, leading him to foresee a gradual rise in packaging costs.

Based on this insight, Li Mingyang conceived the idea of using technology to address this issue and turned to his alma mater, Shanghai Jiao Tong University.

In 2014, Li Mingyang successfully invited Professor Sheng Xinjun, the vice dean of the School of Mechanical and Power Engineering at Shanghai Jiao Tong University and the vice dean of the Shanghai Jiao Tong University Yuanzhi Robotics Research Institute, among others, to co-found JAKA Robotics, which was incubated at the Shanghai Jiao Tong University Entrepreneurship Incubator. In October of the same year, the prototype of the intelligent system was designed and completed.

Leveraging Li Mingyang's strong connections and experience in the beverage packaging industry, JAKA Robotics' robotic arms quickly gained recognition from several domestic dairy manufacturers and achieved batch supplies. In 2015, JAKA Robotics created the first intelligent packaging production line for gift box milk in the Chinese dairy industry, a pioneering move that significantly enhanced production efficiency and reduced labor costs.

Since then, JAKA Robotics has also designed an automatic spandex grading and sorting robotic packaging system for the chemical fiber industry, streamlining a production line that originally required 65 people to just four operators, significantly saving enterprises on labor costs.

To better align with market demand and avoid competing with workers for jobs, JAKA Robotics was determined to develop a new generation of collaborative robots. After relentless efforts, in 2017, it successfully launched its first Xiaozhu series of collaborative robots, breaking the bottleneck in domestic robot body production.

Today, JAKA Robotics' collaborative robot family has expanded to nine series, and it has become the first company in the industry to pass the 80,000-hour MTBF (Mean Time Between Failures) test.

As of now, JAKA Robotics has established bases in Shanghai, Changzhou, Shenzhen, as well as Japan and Germany, with products sold in over 100 countries and regions worldwide. It has deployed more than 10,000 robots in Europe, North America, Japan, South Korea, Southeast Asia, and other regions, serving numerous industry giants in the automotive, electronics, semiconductor, new energy, and other fields, effectively driving the advancement of global industrial intelligent manufacturing.

Additionally, JAKA Robotics actively expands into new commercial consumption areas, applying advanced technology to service scenarios such as catering, retail, and education.

- 02-

Returning to JAKA Robotics' core business, its primary revenue sources are divided into two major parts: one is the sales revenue from collaborative robot products, which accounted for over 95% of total revenue in the first half of 2024; the other is the system integration business centered around collaborative robots.

Collaborative robot products are primarily used for tasks such as material handling and assembly on industrial automated production lines, while the system integration business focuses on providing customized solutions for specific industries.

Compared to traditional industrial robots, JAKA Robotics' products feature a lightweight design, flexibility, strong safety collaboration, and ease of programming. They can closely interact with workers in the same space, enabling human-machine collaborative operations.

For instance, in automotive manufacturing plants, collaborative robots can seamlessly cooperate with workers to complete the assembly of automotive parts, effectively boosting production efficiency and product quality; in the 3C electronics field, they also play a crucial role in the handling and assembly of electronic products.

- 03-

The collaborative robot field in which JAKA Robotics operates has witnessed rapid development in recent years.

China has emerged as the world's largest robot market. According to the World Robotics 2024 Report released by the International Federation of Robotics (IFR), in 2023, China installed 276,000 industrial robots, accounting for 51% of global installations. The industrial robot density reached 470 robots per 10,000 employees, surpassing Germany and Japan to rank third globally.

As the concept of intelligent manufacturing gains traction, many enterprises are accelerating the pace of intelligent transformation in their production processes. Collaborative robots, with their unique advantages, have become one of the key drivers behind this transformation.

JAKA Robotics' customer base includes renowned automakers such as Toyota, Honda, Volkswagen, and SAIC, as well as industry giants like Luxshare Precision, Dongshan Precision, and Schneider Electric, and it provides services to multiple Fortune 500 companies. Notably, JAKA Robotics has become the sole global supplier of collaborative robots to Toyota Motor Corporation.

In terms of suppliers, from 2021 to the first half of 2024, JAKA Robotics' main suppliers included harmonic drive supplier LVH, PCBA supplier Shanghai Juchuan, Jiajietong, and others.

Regarding competitors, JAKA Robotics faces stiff challenges from domestic and foreign peers. For example, UARM Technology, one of the "Three Musketeers" of collaborative robots in the domestic market, was listed on the Hong Kong Stock Exchange at the end of 2024, and international giants such as ABB are also active in this field.

- 04-

Let's now examine JAKA Robotics' financial status.

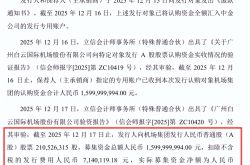

In terms of operating revenue, it showed a steady growth trend from 2021 to 2023. Operating revenue was RMB 175.8347 million in 2021, increasing to RMB 280.7775 million in 2022, and further rising to RMB 349.5562 million in 2023, with RMB 166.7885 million in the first half of 2024. The compound annual growth rate from 2021 to 2023 reached 41%.

However, net profit fluctuations were more pronounced. In 2021, net profit attributable to shareholders of the parent company was -RMB 7.2331 million. In 2022, it turned profitable, reaching RMB 5.7357 million, but it incurred a loss again in 2023, at -RMB 28.5473 million, and -RMB 3.2541 million in the first half of 2024. The prospectus stated that the main reason for not yet being profitable was that it was in the early stages of market and customer introduction, with a relatively small sales scale and significant investments in technology and product research and development, as well as market promotion.

Given that China is the world's largest industrial robot market with continuously increasing installations, and with the acceleration of a new round of technological revolution and industrial transformation, the application of industrial robots in the manufacturing industry is becoming more widespread and in-depth. The collaborative robot industry is expected to maintain a growth momentum in the future.

According to predictions from international market research institutions, the global collaborative robot market size will reach billions of dollars by 2026. For enterprises like JAKA Robotics that have already secured a favorable position in terms of technology and market share, there is still ample room for development.

This article does not constitute any investment advice. Images are sourced from the official website.