50,000 people in 2 weeks: China's manufacturing efficiency far exceeds that of India, no wonder Foxconn and Apple are returning to China

![]() 08/08 2024

08/08 2024

![]() 626

626

According to multiple media reports, Foxconn in Zhengzhou is aggressively recruiting, with nearly 50,000 people hired in the past two weeks alone. This is equivalent to the number of workers that Foxconn's Indian factory had developed over four years, once again highlighting the ultra-high efficiency of Chinese manufacturing and proving that Indian manufacturing is simply not comparable to Chinese manufacturing.

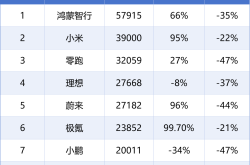

Foxconn was the first of Apple's three major contract manufacturers to set up a factory in India, doing so in 2019. After four years of effort, the number of employees only reached around 50,000 last year. Despite this, the Indian factory has frequently experienced problems leading to worker stoppages.

In contrast, Foxconn Zhengzhou completed its factory construction in just two years and boasts 300,000 employees, making it Apple's largest factory. It is reported that Foxconn Zhengzhou once produced 70% of all iPhones at its peak, but in recent years, due to well-known reasons, the number of Foxconn employees in mainland China has fluctuated significantly.

One of the reasons for this is the shift to Vietnam and India. It is reported that this is a requirement from Apple, which hopes to diversify production capacity to ensure the stability of iPhone manufacturing. In recent years, Foxconn has been enthusiastic about setting up factories in India, and there have even been rumors that Foxconn directly selected Indian employees to learn manufacturing techniques at its factories in mainland China and dismantled production line equipment to transport to India.

However, setting up factories in India has been beset with controversies. Wistron is the second Apple contract manufacturer to set up a factory in India. Wistron was quite resolute about leaving mainland China, directly selling its 80,000-employee factory in mainland China to a Chinese company and focusing on setting up factories in India. However, subsequent events caused Wistron to bitterly regret its decision.

In 2020, Wistron set up a factory in India and, after two years of development, had 10,000 employees there. This scale is only one-eighth of the size of its factory in mainland China, and progress has been quite slow. Immediately afterward, Wistron encountered a forced takeover by an Indian consortium, ultimately forcing Wistron to sell its Indian factory to the Indian consortium Tata. In 2023, Wistron received only 1% of iPhone 15 orders, effectively exiting the iPhone contract manufacturing market.

Having acquired Wistron's Indian factory, the Indian consortium has now set its sights on Pegatron's factory in India. It is reported that Tata is seeking to acquire a controlling stake in Pegatron's Indian factory. Given the strong position of Indian consortia in India, it is widely believed that Pegatron will not escape the fate of being acquired.

The experiences of Wistron and Pegatron have caused Foxconn considerable concern, and Foxconn has quickly reduced its planned expansion of employee numbers at its Indian factory from 70,000 to 50,000. In fact, Foxconn is already facing difficulties at this point, as a factory it built in India for a Chinese mobile phone company has had its orders stolen by a local Indian contract manufacturer. It is reported that Foxconn has lost 70% of its orders, leading to a significant exodus of senior executives and employees from its Indian factory.

Today, Foxconn Zhengzhou has recruited 50,000 employees in just two weeks, a number equivalent to the growth of Foxconn's Indian factory over four years. This demonstrates the efficiency of China's manufacturing sector. At the same time, it also reflects the flexible production capacity advantage of Foxconn's factories in China. Apple sells 60% more iPhones in the fourth quarter of each year than in the other three quarters, and only Chinese manufacturing can accommodate such a quarterly increase in production capacity.

In addition, iPhones manufactured in India also face issues of low yield rates. In 2023, Apple produced the iPhone 15 both in India and China, but the yield rate of iPhones produced in India was as low as 50%, far below China's 90%. iPhones produced in India and shipped to Europe were also found to have excessive levels of E. coli, causing significant disappointment for Apple and leading to an increase in iPhone 16 production capacity in China this year.

This reality undoubtedly demonstrates the efficiency and high quality of Chinese manufacturing. Apple and Foxconn's foray into India can be seen as a major setback, and their current significant increase in iPhone production capacity in China can be seen as a lesson learned from their experiences in India. Let's hope this year's iPhone 16 production goes more smoothly. Chinese manufacturing is not so easily replaced.