Power Batteries Experience First Price Increase of the New Year: Why Are Automakers Not Reacting Strongly?

![]() 01/07 2026

01/07 2026

![]() 381

381

It's Not a Demand-Driven Bull Market

Written by: Chen Dengxin

Edited by: Li Wenjie

Formatted by: Annalee

New energy vehicles (NEVs) have achieved remarkable success.

Leapmotor, Xiaomi, and XPeng have all met their annual sales targets. Meanwhile, brands like AITO, NIO, Zeekr, and Fangchengbao have also performed exceptionally well, fostering a highly competitive environment among top players.

However, challenges are beginning to surface.

The increase in lithium carbonate prices has impacted the power battery sector, with lithium iron phosphate (LFP) batteries leading the charge in price hikes. After entering 2026, another price increase of 1,000 yuan per ton has sparked widespread discussion.

Will automakers find themselves in a difficult position amid rising power battery prices and industry efforts to combat internal competition?

Profit Redistribution Is No Simple Matter

New energy vehicles have become the preferred choice for consumers.

Public data indicates that the penetration rate of NEVs was less than 10% in 2020 but surpassed 60% by 2025, making traditional fuel vehicles a minority.

This shift means that every move by power battery manufacturers increasingly affects the end market.

Specifically, there is significant debate over the 2026 price trend of LFP batteries, which hold over 80% of the market share. Pessimists and optimists hold starkly different views.

One perspective suggests that price increases are inevitable.

Currently, lithium carbonate prices have doubled from their lowest point in June 2025, triggering a chain reaction that has led to price increases across the entire lithium battery supply chain.

Lithium carbonate futures prices have exceeded 140,000 yuan per ton.

A supply chain insider told the media, "Now, for every battery produced, raw material costs are nearly 20% higher than six months ago."

In this context, it is reasonable for power battery prices to rise accordingly.

More critically, companies have long hoped for price increases: from the end of 2022 to August 2025, LFP material prices plummeted from 173,000 yuan per ton to 34,000 yuan per ton, an 80.2% drop, leading to sustained industry-wide losses.

Thus, further price increases in 2026 are highly likely.

CITIC Securities stated, "The current profitability of LFP batteries is at a cyclical low. With improvements in supply and demand dynamics, there is potential for recovery, and LFP battery profits may reach a cyclical turning point."

Another viewpoint suggests that weak demand will slow price increases.

The NEV purchase tax exemption has been reduced from full exemption to a 50% reduction, causing some demand for LFP batteries to shift earlier. Additionally, as the off-season arrives, the tight supply of power batteries has eased.

This is evident from production schedules.

Industry data shows that in January 2026, the global pre-production schedule for power battery companies totaled 161.04 GWh, down 3.8% month-over-month. Among them, Chinese companies' pre-production schedules totaled 142.44 GWh, down 4.2% month-over-month.

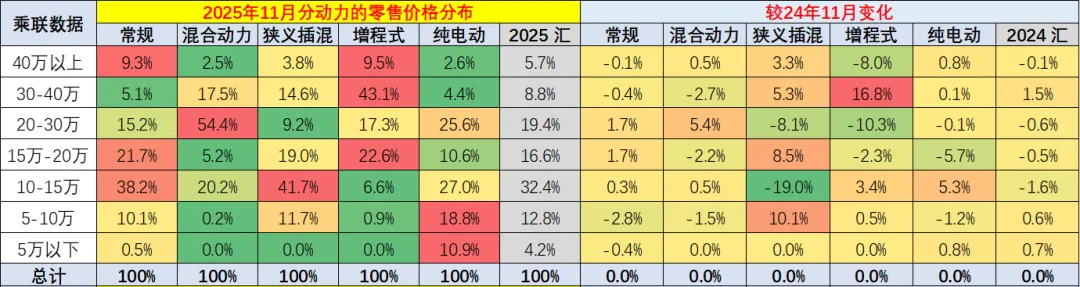

Source: Cui Dongshu, Secretary-General of the China Passenger Car Association

In short, earlier demand has been somewhat exhausted, and the foundation for future price increases is not solid.

Tang Yan, Deputy Secretary-General of the China Industrial Association of Power Sources, said, "The lithium battery supply chain is undergoing a test of 'fire and ice': on one hand, driven by new energy vehicles, demand for LFP materials has surged; on the other hand, cost pressures on LFP materials have not been fundamentally alleviated, and issues like disordered competition and unreasonable profit distribution across the supply chain persist."

In plain terms, power battery price increases are merely a result of profit redistribution in the lithium battery supply chain, not a bull market driven by downstream demand.

From this perspective, LFP battery price increases in 2026 may not proceed as desired.

Limited Room for Automakers to Make Concessions

The debate over power batteries is unlikely to be resolved soon, but one certainty is that automakers have not panicked.

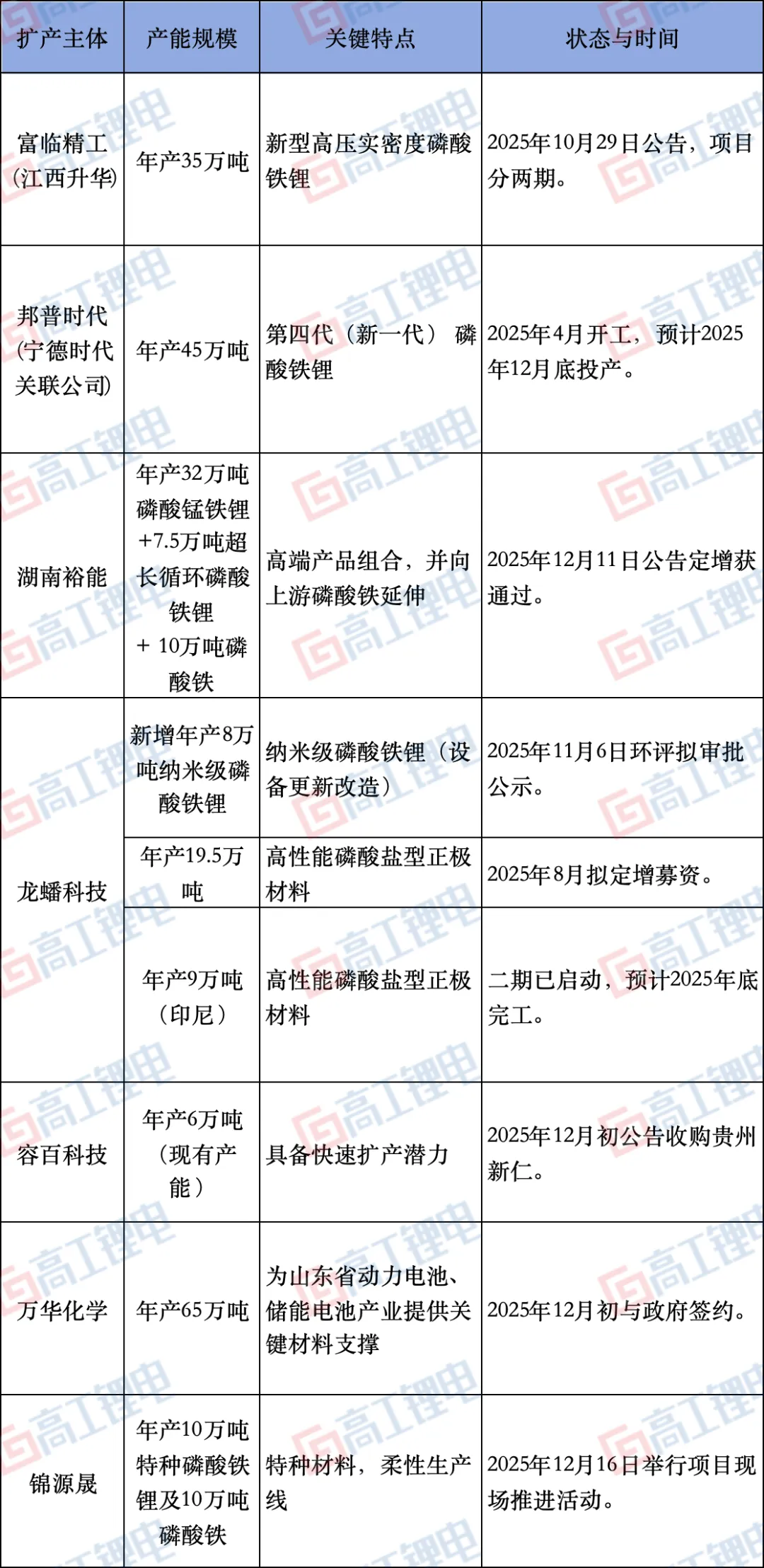

First, active expansion has increased supply.

It is well known that when a cyclical industry becomes visibly profitable, capital flows in, leading to sustained supply growth and curbing price increases, ultimately resulting in a short-lived boom.

Power batteries are no exception.

With recent improvements in industry profits, clear signals have emerged: data from Gaogong Industry Research Institute shows that in 2025, China planned approximately 64 new lithium battery projects (including signed agreements, announcements, and construction starts), with a total planned capacity exceeding 1,100 GWh, a 105% year-over-year increase. In terms of investment, the total planned investment for the year reached 348.5 billion yuan, a 92% year-over-year increase.

In other words, under the leadership of battery companies like CATL, CALB, EVE Energy, and Chugneng New Energy, previously idled capacity will soon recover and even reach new highs, limiting the duration of power battery price increases.

Source: Gaogong Lithium Battery

Second, sodium-ion batteries offer an alternative.

To avoid being held hostage by another surge in lithium carbonate prices, the industry has invested heavily in sodium-ion batteries, providing a backup plan in case lithium battery prices spiral out of control.

In fact, as early as the 1970s, when new energy vehicles were in their infancy, both sodium-ion and lithium-ion batteries entered automakers' radars. However, sodium-ion batteries were eliminated due to their inherently lower energy density, which did not meet market requirements.

As a result, sodium-ion batteries were overshadowed by lithium-ion batteries and gradually marginalized, going unnoticed for a considerable period.

Now, with technological maturity, these pain points have been addressed.

For example, CATL's second-generation sodium-ion battery has an energy density of 175 Wh/kg and a cycle life exceeding 10,000 cycles, meeting automotive standards.

CATL revealed in its investor relations activity record, "Our new sodium-ion battery has passed the new national standard certification, becoming the world's first sodium-ion battery to do so. Sodium-ion passenger vehicle power batteries are being developed and commercialized with clients, with smooth progress."

Another example is HiNa Battery's sodium-ion battery solution for commercial vehicles, which achieves an energy density exceeding 165 Wh/kg and a cycle life exceeding 8,000 cycles.

Li Shujun, General Manager of HiNa Battery, said, "Now is the most critical period for sodium-ion battery development. 2026 will be the true year of commercialization. As scale expands and energy density improves, sodium-ion battery costs are expected to halve within the next two to three years."

Sodium-ion and lithium-ion batteries share similar working principles and manufacturing processes. Once energy density and manufacturing costs are no longer barriers, their competitive edge will be significant.

After all, sodium-ion batteries offer advantages in scenarios like overcharging, overdischarging, and overvoltage.

Notably, they do not experience significant performance degradation in low-temperature conditions: CATL's test data shows that under extreme cold, a vehicle with a 2.95-meter wheelbase equipped with a second-generation sodium-ion battery can achieve a pure electric range exceeding 200 km in hybrid mode and over 500 km in pure electric mode.

Third, automakers' bargaining power has increased.

There was a time when automakers were easily controlled by leading battery manufacturers, leading to complaints about who they were really working for. Companies like XPeng, Leapmotor, Li Auto, and NIO have intentionally or unintentionally supported players like Sunwoda and CALB to avoid a repeat of past issues. Even those favoring leading battery manufacturers have adopted dual-supplier systems with CATL and BYD to prevent monopolies.

As a result, CATL's domestic market share dropped from 53% in 2021 to 43% in 2025, giving automakers greater influence.

Mo Ke, founder of Real Li Research, said, "From the battery production side, rising material costs will inevitably force battery price increases. However, from the demand side, the conclusion may be the opposite. Product prices are jointly determined by supply and demand. If buyers (automakers) do not accept price increases proposed by suppliers (battery manufacturers), the increases will not materialize. Moreover, buyers typically have stronger bargaining power, while battery manufacturers are relatively weaker."

In retrospect, automakers have valid reasons not to make excessive concessions.

The NEV market is fiercely competitive, and while combating internal competition has become an industry consensus, price wars remain intense, with average NEV prices declining for three consecutive years.

Source: LatePost Data

More critically, industry inventory levels are high.

Data from the China Passenger Car Association shows that as of late November 2025, national passenger vehicle inventory stood at 3.79 million units, 590,000 units higher year-over-year. Inventory supported future sales days increased by 13 days year-over-year.

In summary, while the surge in lithium carbonate prices is forcing power battery price increases, automakers at the end of the supply chain face challenges in escaping internal competition and will naturally resist cost increases. The clash between the two sides will intensify in 2026, as neither wants to become a sacrificial lamb in the rebalancing of industrial profit chains.

Ultimately, only time will tell the outcome.