ZEISS Smart Services Dashboard Enhances Stable and Efficient CMM Utilization

![]() 01/14 2025

01/14 2025

![]() 502

502

Amidst intensifying global competition, evolving industrial structures, and internal corporate realignments, enterprises are constantly bombarded with inquiries regarding production schedules. In response, production departments have embraced digital and intelligent display systems for enhanced planning and quality control. As a pivotal department in the enterprise production chain, the testing department's drive towards digitization and intelligent transformation of equipment testing capabilities and plans becomes crucial for companies aiming to break through development bottlenecks.

ZEISS's innovative Smart Services Dashboard, a digitally advanced service product, facilitates the monitoring of testing equipment status, optimizes management processes, and boosts production efficiency.

Discover the ZEISS Smart Services Dashboard

In essence, the ZEISS Smart Services Dashboard is an intelligent system that offers real-time, accurate insights into the key performance indicators and usage details of one or multiple ZEISS Coordinate Measuring Machines (CMMs). Whether in the office or on the go, users can access the equipment's real-time status and optimize measurement process planning anytime, anywhere, with just an internet connection. Should any abnormalities arise, the system promptly sends notifications. This high level of transparency enables comprehensive equipment monitoring, ensuring stable and efficient CMM operation during measurement tasks, thereby safeguarding production.

In the Industry 4.0 era, data connectivity is paramount. With the aid of ZEISS Smart Services, the full potential of ZEISS measurement solutions is unleashed, maximizing efficiency. Enterprises benefit from heightened equipment availability, enhanced measurement process safety, and substantial productivity improvements.

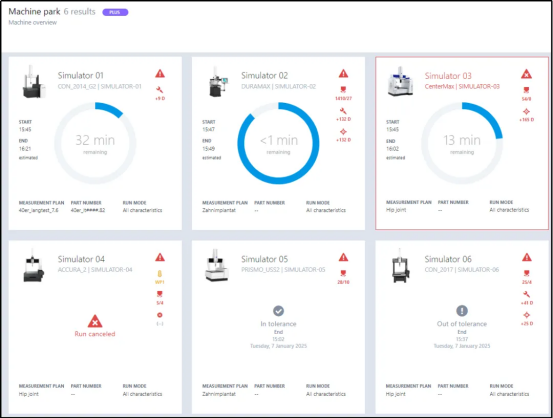

Remote Management and Monitoring for Real-Time Measurement Task Insight

Upon deploying the Smart Services Dashboard, managers can achieve remote management and monitoring at their convenience, significantly reducing travel time costs and enabling rapid decision-making based on real-time data. This effectively mitigates production delays due to information lags, ensuring the efficient and smooth operation of the entire production process.

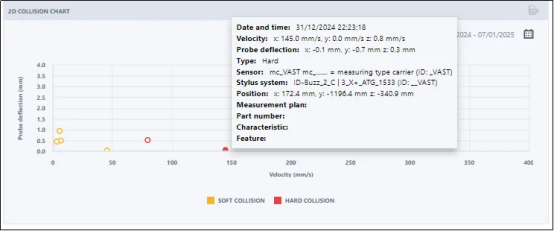

Active Stylus Collision Risk Warning for Timely Measurement Program Optimization

Regarding equipment maintenance and lifespan extension, the system addresses the thorny issue of stylus collisions with an active warning function. This prompts enterprises to promptly optimize measurement programs and standardize measurer operation procedures. Each reduction in stylus collision incidents protects the equipment's key components from impact, significantly reduces the wear rate of vulnerable parts like probes, thereby extending probe lifespan and lowering the high costs associated with frequent part replacements.

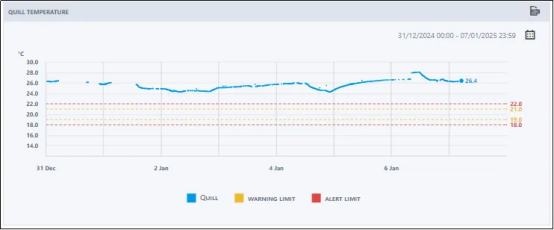

Precision Temperature Monitoring to Safeguard Measurement Accuracy

Industrial production environments are complex and variable, where even minor temperature fluctuations can interfere with measurement accuracy. Leveraging real-time temperature information from the dashboard, operators can promptly and accurately adjust environmental parameters, ensuring the stability and reliability of each measurement data. This provides a robust guarantee for product quality from the source and effectively prevents the increase in defect rates due to measurement errors, thereby reducing rework losses.

Insight into Single and Multiple CMM Utilization Rates for Optimized Resource Allocation

From a resource utilization maximization perspective, the system offers enterprises detailed information on the utilization rates (including shift operations) of single and multiple ZEISS CMMs. This enables enterprises to accurately gauge equipment idle and busy periods, reasonably arrange production plans, flexibly allocate human and material resources, fully exploit equipment potential, avoid prolonged idleness or overuse, and ensure each piece of equipment operates at maximum capacity at the right time, thereby enhancing overall production efficiency.

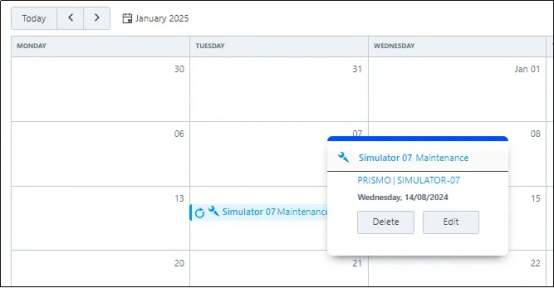

Periodic Maintenance and Calibration Reminders for Stable Equipment Operation

The periodic maintenance and calibration reminder function acts as an "equipment health manager," constantly reminding enterprises to prioritize equipment health. Based on the equipment's operating hours and working condition data, the system accurately predicts maintenance nodes and sends reminder information in advance, ensuring timely professional maintenance, component replacement, and accuracy calibration. This keeps the equipment in optimal operating condition at all times, eliminating the risk of production stoppages due to sudden equipment failures.

One-Click Direct Connection to ZEISS After-Sales for Efficient Problem Resolution

When confronted with challenging issues, simply create a customer support work order within the system to seamlessly connect with ZEISS's professional after-sales team. Leveraging deep technical experience and expertise, the expert team swiftly responds with remote guidance, troubleshooting, or on-site technical support, minimizing the impact of equipment failures on production.

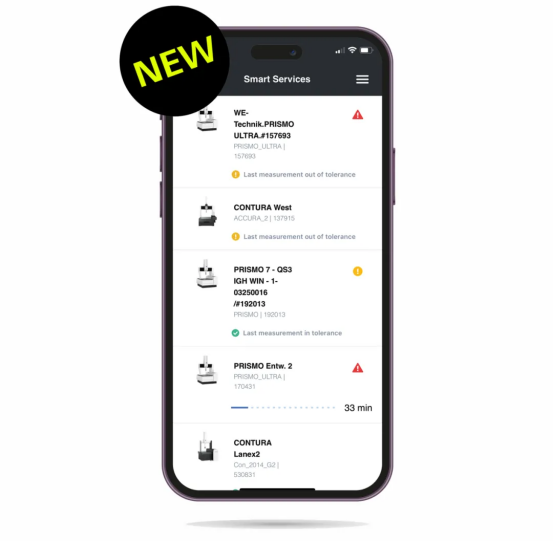

Instant Message Push for Convenient Management

By installing the "Cloud Connector" client on the CMM workstation, users can effortlessly view real-time data by simply opening a webpage on any computer, facilitating the setup of large screens for equipment monitoring. In Windows notification mode, critical conditions are proactively pushed to users' attention, ensuring no important information is overlooked. Additionally, the free mobile app further enhances usability, allowing users to receive push notifications anytime, anywhere, staying abreast of critical conditions in real-time, truly realizing mobile and immediate management.

Comprehensive Data Security Protection for Robust Information Security

The Smart Services Dashboard has established a robust security protection system for enterprises. It complies with international standards such as ISO 27001, HIPAA, FedRAMP, SOC1, and SOC2 and is certified and audited by Microsoft data centers. Each communication link used by the "Cloud Connector" program implements 256-bit encryption at the transport layer through the Advanced Encryption Standard (AES) TLS 1.2 (Secure AMQP Protocol - AMQPS or WebSockets). Furthermore, equipment and personnel are bound, and permissions are strictly differentiated, ensuring that only authorized personnel can access critical information, thereby building multiple layers of security for the enterprise's data assets.