Qinghua Graduate Leads Logistics Robot Company in Jiaxing to HKSE Listing: Annual Revenue Hits RMB 721 Million

![]() 07/21 2025

07/21 2025

![]() 590

590

Recently, Zhejiang Carrier Technology Group Co., Ltd. (hereinafter referred to as Carrier) submitted its prospectus to the Hong Kong Stock Exchange.

Carrier specializes in smart in-plant logistics robots, encompassing three key product lines: Multi-Shuttle Robot (MSR), Autonomous Mobile Robot (AMR), and Conveyor Sorting Robot (CSR).

This marks the second logistics robot company to file for an IPO at the Hong Kong Stock Exchange, following the listing of Geek+ on July 9th.

- 01 -

Carrier was founded in 2014 by Gu Chunguang.

Born in 1970, Gu graduated with a bachelor's degree in mechanical engineering from Tsinghua University and later earned a Ph.D. in the same field from the Massachusetts Institute of Technology. After his Ph.D., Gu worked at i2 Technologies, a supply chain management software company, and Boston Consulting Group.

Subsequently, Gu joined Jiuzhoutong Pharmaceutical Group, where he became the CTO in 2008, aiding the company in establishing intelligent warehousing systems nationwide. During his tenure, he also led the establishment of Hubei Jiuzhou Tongda Technology Development Co., Ltd., which focused on intelligent logistics systems for pharmaceuticals. This startup later became the precursor to Carrier.

In 2014, Gu founded Carrier in Wuxi, focusing on logistics robots, intelligent equipment manufacturing, and one-stop technical services. That same year, the company developed a four-way shuttle, which was launched into the market the following year.

Notably, during the clamping test of the four-way shuttle, while international manufacturers use 1 million tests as a standard, Carrier insisted on conducting over 1 million tests. By analyzing worn parts, Carrier optimized its design. Besides the vehicle's design, Carrier also considered various storage environment needs, such as box size, storage density, vehicle scheduling, and maintenance. This holistic approach cultivated Carrier's capabilities in software, electronic control, project implementation, and after-sales services, ultimately earning customer trust.

In 2016, Carrier relocated to Jiaxing. In 2017, it acquired Hubei Jiuzhou Tongda, solidifying its position as today's Carrier.

Since its inception, Carrier has completed multiple funding rounds, culminating in a valuation of RMB 3.5 billion after the E round. Its shareholders include CIC Fund, SF Technology, China Merchants Advanced Technology, Yangtze River Pharmaceutical Group, Summit View Capital, One Village Capital, Cornerstone Capital, Jiaxing Science and Technology City, and Jiuzhoutong Group. Notably, CIC Fund, SF Technology, and China Merchants Advanced Technology hold shares of 10.15%, 8.46%, and 6.48%, respectively.

Interestingly, one of Carrier's shareholders, SF Express, is also a customer. Carrier provides SF Express with intelligent logistics robot solutions, encompassing system development, core automation hardware supply, and on-site installation and integration.

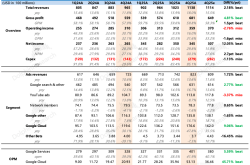

In 2022, 2023, and 2024, Carrier's revenues were RMB 657 million, RMB 551 million, and RMB 721 million, respectively. Its adjusted net losses for these years were RMB 117 million, RMB 123 million, and RMB 50.451 million, respectively.

Carrier's primary revenue source is the sale of robots and systems. In 2024, this segment generated revenue of RMB 703 million, accounting for 97.4% of total revenue. After-sales service and other business revenues amounted to RMB 18.665 million, accounting for 2.6% of total revenue.

- 02 -

In 2020, the Chinese market for in-plant logistics robots was valued at approximately RMB 13.9 billion, growing to RMB 44 billion in 2024. It is projected to reach RMB 133.9 billion by 2030, accounting for nearly 40% of the global market. This implies an average annual compound growth rate of approximately 20.4% for the Chinese market from 2024 to 2030.

Compared to the global market, the Chinese market is growing at a faster pace. In 2024, the Chinese market accounted for approximately 37% of the global market, and this share is expected to reach 40% by 2030.

In the manufacturing sector, in-plant logistics robots are being rapidly adopted to facilitate automated production material distribution and flexible manufacturing. The automotive and electronics industries lead in robot applications. China's vast manufacturing capacity, coupled with factories' pursuit of cost reduction, efficiency enhancement, and flexible production, is driving a surge in demand for AGVs, handling robots, and other equipment.

The application of in-plant logistics robots in e-commerce warehousing and express logistics is the most mature, fostering the largest market increment. Robots are pervasive in e-commerce warehouses, from storage, picking, packaging, to sorting. Compared to manual handling, AGV robots can enhance efficiency by up to 400%, significantly reducing package inbound, outbound, and sorting times while minimizing error rates.

In the medical field, material distribution and logistics within hospitals represent a new blue ocean for robot applications. Recently, over 100 large hospitals nationwide have introduced logistics robots for the automated transportation of medicines, reagents, samples, surgical instruments, etc. The industry anticipates the medical logistics robot market to expand at an annual growth rate of over 20% in the coming years, emerging as a new incremental segment for in-plant logistics robots.

With the development of the fresh food, e-commerce cold chain, and pharmaceutical vaccine industries, cold chain warehousing is emerging as another application scenario for in-plant logistics robots. The challenging operating environment of cold storage (usually below -20°C) makes it difficult for humans to work there for extended periods. In response, domestic enterprises have developed low-temperature-resistant warehousing and handling robots and unmanned forklifts.

Despite its promising future, the Chinese in-plant logistics robot industry faces numerous challenges and bottlenecks during its development.

Deploying logistics robots often requires substantial upfront investment, including equipment procurement, system integration, and site modification. For small and medium-sized enterprises, the financial burden is significant, and the long cost recovery cycle is a major concern when considering robot adoption.

As costs decline and solutions mature, it is anticipated that small and medium-sized warehouses and factories will also adopt robots en masse, realizing the transition to "unmanned warehouses" and "unmanned factories." By 2030, the robot penetration rate in large warehouses is expected to increase from the current 20-30% to over 50%. The demand for automation transformation in small and medium-sized warehouses will also be unleashed, shifting market demand from "a few benchmark projects" to "large-scale popularization."

The logistics robot sector is in a phase of rapid development, with different manufacturers lacking unified standards for navigation methods, communication protocols, and scheduling systems. This leads to compatibility and interconnection issues.

Logistics scenarios vary widely, with different industries and warehouses having distinct robot requirements. Currently, many solutions are customized projects with "one case, one design," resulting in high development and implementation costs and long cycles, making rapid replication difficult. Under this model, companies often experience low gross profit margins. In the future, customers will prefer suppliers that can provide end-to-end overall solutions rather than just individual devices. Leading companies will likely adopt a "full-stack" approach.

The content of this article is for reference only and does not constitute investment advice. This article also references Jiaxing Daily's "Gu Chunguang: Building a World-Class Enterprise by Nanhu Lake," for which we express our gratitude.