The combination of nanotechnology and porous IrO2 coating technology, Swedish Ionautics launches innovative solutions in the field of green hydrogen production

![]() 05/10 2024

05/10 2024

![]() 732

732

Against the backdrop of the global pursuit of carbon neutrality, hydrogen, as a clean and carbon dioxide-free energy carrier, has become particularly important. However, the high carbon emissions in the current hydrogen production process and the challenges faced by PEM electrolysis technology, such as scarcity of metal resources and low efficiency, have limited its large-scale application. It is in this context that Swedish Ionautics emerged, successfully developing a scalable patented nanoparticle technology that is ingeniously applied to the manufacture of noble metal oxide nanoporous layers, which are further used as anodes for polymer exchange membrane water electrolysis (PEMWE). This innovation not only optimizes the performance of PEM electrolysis technology but also effectively improves its efficiency.

Ionautics Nano Particle Technology

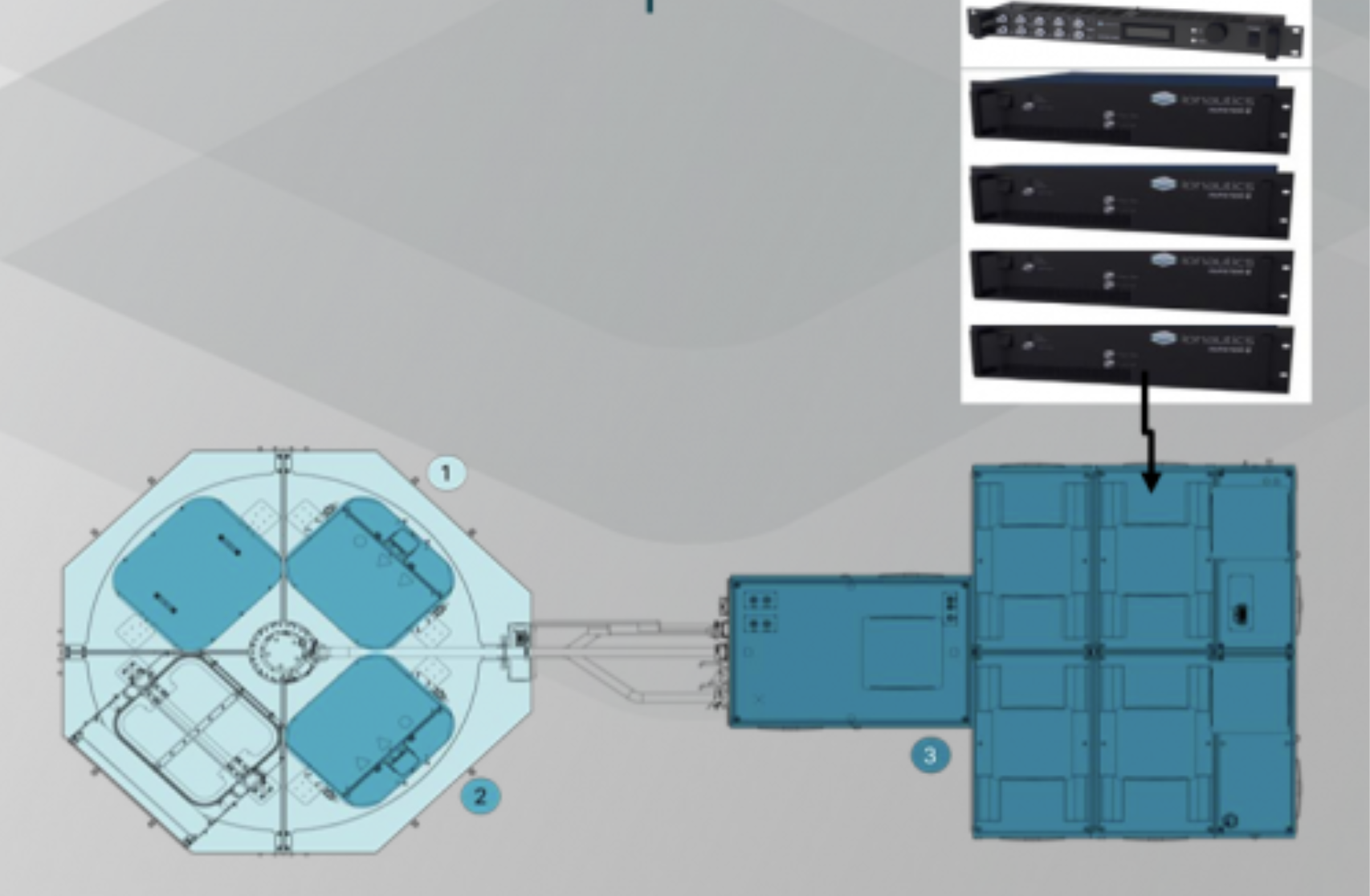

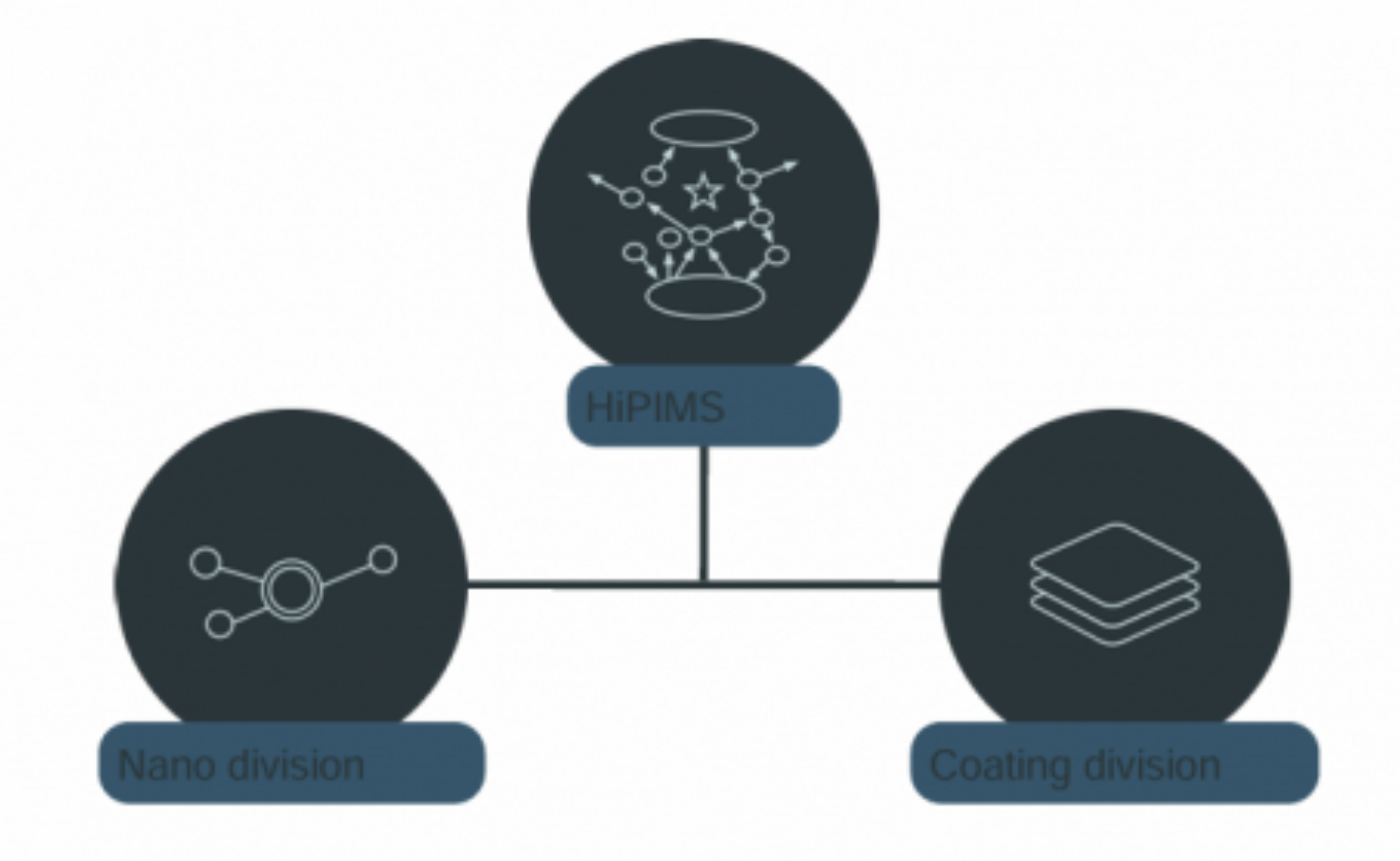

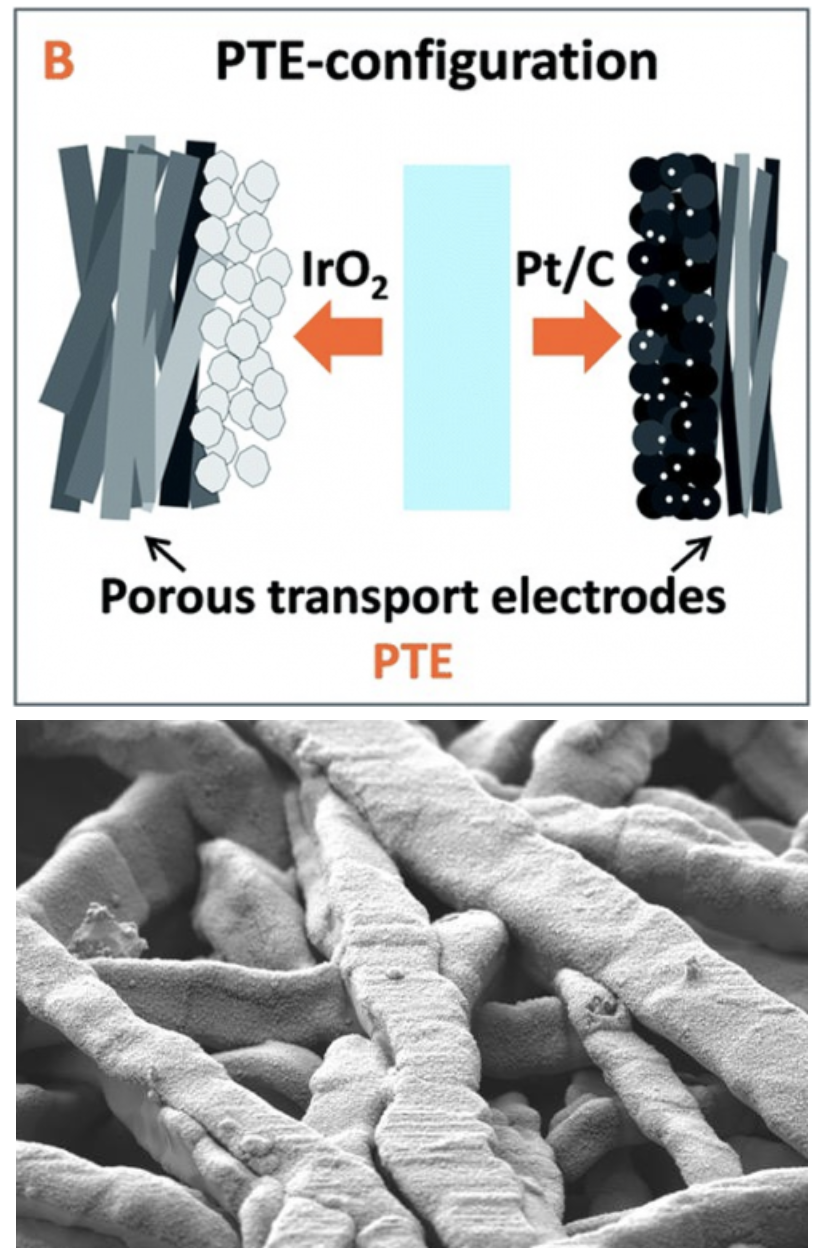

Ionautics' core technologies include Hipims, Nano, and e-CVD. Among them, Nano technology is the key to scaling up green hydrogen production. Nano technology provides a revolutionary solution for scaling up green hydrogen production. Through unremitting efforts, we have successfully developed a unique nanoparticle source and obtained patent protection. This innovative nanoparticle source is crucial for the manufacturing of catalytic electrodes in PEM electrolyzers, revolutionizing the traditional electrode production method.

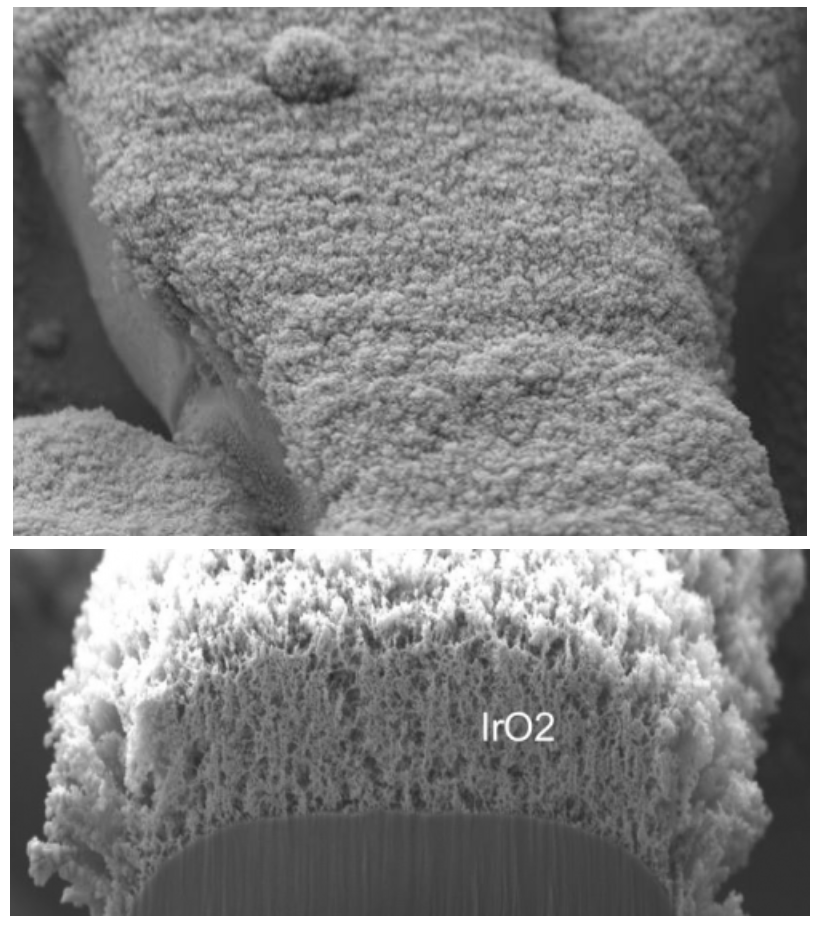

By combining hollow cathode targets and high-power pulse technology, Ionautics achieves a high ionization rate, ensuring rapid growth of uniform nanoparticles. This revolutionary efficiency in material demand not only reduces the demand for inert metals to 2-10% of the current level but also demonstrates the same or higher efficiency as the best R&D electrodes in concept validation stage tests. This breakthrough progress lays a solid foundation for the large-scale application of PEM electrolysis technology. In the face of the urgent demand for a global carbon-neutral economy, hydrogen, as a clean and efficient energy carrier, is receiving increasing attention. However, most hydrogen production still relies on gray hydrogen, which is not only inefficient but also produces a large amount of greenhouse gas emissions. In contrast, carbon dioxide-free hydrogen produced by PEM electrolysis is more suitable for renewable energy applications.

However, PEM electrolysis technology has been constrained by the scarcity and high cost of critical metals such as iridium and platinum. In addition, its efficiency is still insufficient compared to gray hydrogen production, requiring at least a 30% improvement to be competitive in the market. These challenges have made it economically difficult to scale up PEM electrolysis. However, Ionautics' technological breakthrough has brought hope for the future of PEM electrolysis technology. By significantly reducing the usage of expensive materials and improving production efficiency, our technology provides the possibility for large-scale application of PEM electrolysis technology.

Here are examples of nanoporous titania coatings on porous transport layers:

Applications of NANO Nanoparticle Technology

Ionautics' Nano particle technology not only has a wide range of applications and significant features, but also shows tremendous development potential in new business areas such as sensor technology and healthcare. Its excellent thin-film properties, hard, smooth, and dense coating characteristics make this technology promising in various fields such as aerospace, energy, and environmental protection. Meanwhile, to ensure the provision of high-quality samples, Ionautics demonstrates strong strength in the aerospace field, with a team of senior scientists focused on the research and development and optimization of nanostructured coatings. We work closely with academic scientists to provide electrolyzer design and optimization services. Our employees rely on rich material characterization experience and advanced equipment to ensure excellent product performance, and actively collaborate with customers and suppliers to optimize production systems to ensure high-quality product supply.

Research and Development Collaboration

We continuously optimize the catalyst layer to enhance performance and production efficiency. With the aid of internal PEMWE testing and advanced material characterization technology, we delve into the performance of the catalyst layer. We have now developed upgraded methods suitable for larger surfaces and rely on an international scientific network to continuously drive product improvement and innovation. In terms of collaboration, we have established close ties with several Swedish partners to jointly explore the development of new catalyst layers/materials.

Ionautics is also closely collaborating with PVD system suppliers, and we are committed to achieving the manufacture of the first full-scale PTL in an industrial production system in the near future. This milestone achievement will strongly demonstrate Ionautics' firm steps in promoting the green energy revolution. We always focus on the research, development, and application of nanotechnology, contributing more to the global carbon neutrality target. We welcome contact with us to jointly move towards a green energy future. If you are interested in us, please contact the regional distributor on our official website.