Exploring the Finger Count: The Versatility of Dexterous Hands

![]() 07/31 2025

07/31 2025

![]() 576

576

Editor's Note: The key to robots achieving true "dexterity" lies in their final centimeter of innovation—the dexterous hand. This integration of machinery, sensing, and AI technology transcends the limits of traditional grippers, evolving from an industrial tool to a more autonomous "humanoid agent."

Amidst the burgeoning field of embodied intelligence, dexterous hands have taken center stage. Star River Frequency has curated a series of articles dedicated to delving into the core of this technological revolution, encompassing "touch," "manipulation," and "creation."

We will not only highlight the intricate technology behind these agile joints but also delve into the profound considerations regarding "capability boundaries" and "human-machine symbiosis" amidst this technological fervor.

Together with forward-thinking peers, we aim to uncover the ultimate boundaries of human-machine collaboration achievable through these "dexterous hands."

Author | Mao Xinru

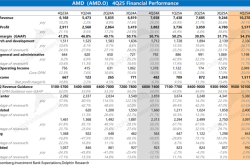

Competition in the field of dexterous hands knows no bounds—a phrase that aptly describes the current landscape. At the recent WAIC, InTime Robotics and Lingxin Qiaoshou unveiled their latest products, the RH56F1 series and the Linker Hand "Industrial Master," respectively. On social platforms, the dexterous hands of Aoyi Technology and StrongBrain Intelligence have garnered significant attention from netizens.

As a crucial component determining the operational capabilities of robots and accounting for about 20% of the cost of humanoid robots, dexterous hands have garnered substantial attention. Currently, this field not only encompasses multiple technical routes but also lacks standardization in hand design.

It's noteworthy that three-finger, four-finger, and five-finger dexterous hands have all embarked on the path to commercialization.

Three-Finger: The Transition from Gripper to Dexterous Hand

A three-finger dexterous hand is not a simplified version of a five-finger hand but an independent form optimized for specific needs, embodying the pragmatic philosophy of "good enough." From a planar perspective, only three points can form a plane. Thus, for the concept of a dexterous hand, three fingers represent the entry-level form, with two fingers merely constituting a gripper.

From a biomechanical standpoint, while the human hand has five fingers, 80% of daily grasping tasks are collaboratively completed by the thumb, index finger, and middle finger. This led to the concept of "functional three fingers," which suggests that by strategically arranging the spatial relationship of these three fingers, the essential manipulation abilities of the human hand can be replicated.

From an engineering perspective, three-finger dexterous hands offer notable advantages:

- Cost Reduction: The driving unit is reduced by over 50%, simplifying the transmission, control, and sensing systems.

- Simplified Control: The decrease in degrees of freedom significantly lowers the complexity of motion planning and force control algorithms.

- Increased Reliability: Fewer moving parts result in lower failure rates and extended service life.

Its design philosophy aims to maximize operating capabilities in core application scenarios with minimal mechanical complexity and cost.

By optimizing finger layout and granting critical degrees of freedom to the thumb, the three-finger dexterous hand can efficiently accomplish precision grasping, power grasping, and some in-hand manipulations, such as rotating objects.

Research by institutions like the Harbin Institute of Technology has proven that a well-designed three-finger structure can meet the needs of most tasks in terms of grasping space coverage and stability. The study also highlights that in "degraded states" where some sensors fail, the simplicity of the three-finger structure facilitates easier and more efficient stability recovery algorithms.

In 1974, the Okada dexterous hand developed by the Japan Electric Laboratory was a seminal early representative. This three-finger design with 11 degrees of freedom could perform continuous and smooth grasping movements.

Currently, there are three notable domestic three-finger dexterous hand products: DexHand 021S by Lingqiao Intelligence, Dex3-1 by Unitree, and myGripper H100 by Elephant Robotics.

Lingqiao Intelligence's DexHand021S is a three-finger dexterous hand priced at 1,000 yuan, suitable for education, agriculture, service, and other scenarios. It boasts 8 degrees of freedom, weighs 620g, and employs rigid-flexible coupled transmission technology—a triple-mode transmission combining gears, tendons, and linkages. Through specially woven flexible ropes and visual-tactile servo linkage, it achieves adaptive grasping force. With a lifespan of 200,000 cycles and ease of maintenance, it is ideal for industrial production lines, logistics sorting, and agricultural picking.

Through modular design and multi-modal data interfaces, combined with low cost, it effectively aids in grasping and AI model research.

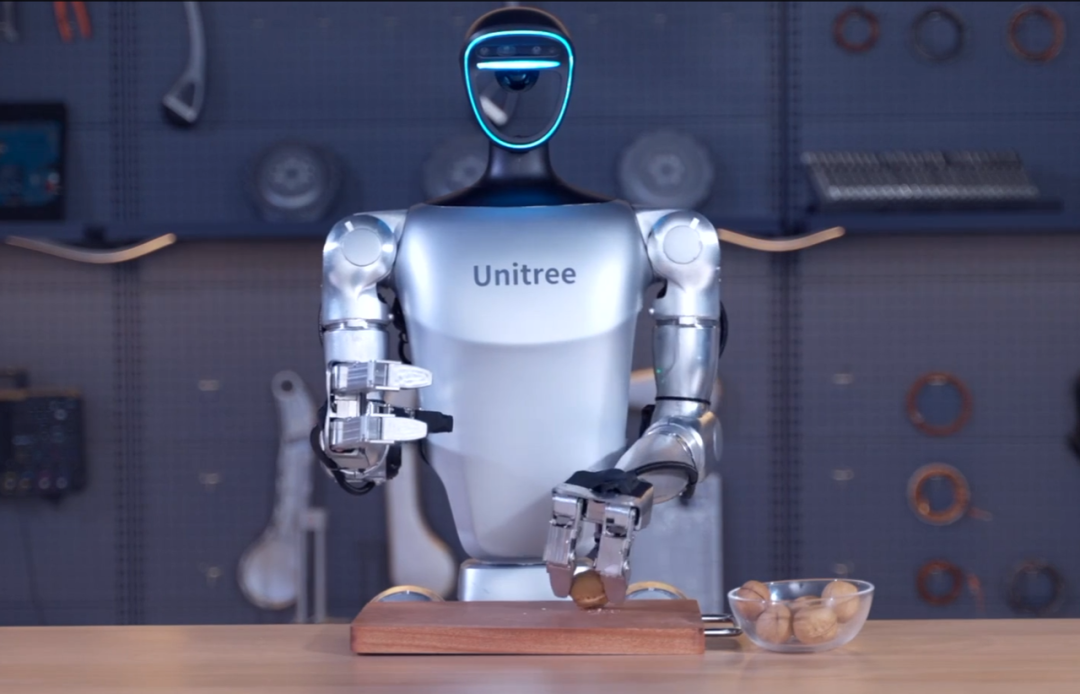

While Unitree's G1 often appears in performances wearing "black gloves," it primarily uses three-finger dexterous hands for indoor operation demonstrations. As a humanoid robot company with self-developed hardware as its core competency, Unitree has ventured into dexterous hand R&D to complement its robots. It has launched the three-finger Dex3-1 and the five-finger Dex5-1.

Dex3-1 weighs 710g, has 7 degrees of freedom and 7 motion joints, and a maximum load of 500g. Each hand is equipped with 33 tactile sensors, enabling precise force perception from 10g to 2500g.

myGripper H100 is a three-finger dexterous hand developed by Elephant Robotics for robotics research, teaching, commercial applications, and other scenarios. It has 6 degrees of freedom, weighs about 700g, and has a maximum load of 500g, capable of simulating 8 natural human finger actions like holding, pinching, twisting, pulling, pushing, pressing, grasping, and lifting. Equipped with a 10-level adjustable torque design, it supports load adjustment within 0-500g, has a gripping range of 0-150mm, and a single-joint movement speed of 60°/s, priced at 6999 yuan.

While these three dexterous hands may be relatively heavy in terms of parameters, their performance aligns with the characteristics of "function-oriented" and "engineering optimization" in suitable scenarios.

The three-finger dexterous hand has transcended the obsession with "complete anthropomorphism," establishing an optimal balance of "cost-control, complexity, reliability, and function coverage."

Four-Finger: The Intermediary Between Three and Five Fingers

The origins of four-finger dexterous hands can be traced back to 1998 with the DLR Hand I launched by the German Aerospace Center. Each finger has 4 joints and 3 degrees of freedom, with nearly 30 sensors per finger. It was the most complex and highly integrated dexterous hand in the world at that time.

Subsequently, the German Aerospace Center launched multiple four-finger dexterous hands, including DLR Hand II, DLR-HIT Hand, Dexhand, and Spacehand. These hands were originally designed for the International Space Station to perform extravehicular operations tasks, such as removing insulation covers and using tools like screwdrivers. In the harsh space environment, robot dexterous hands can replace astronauts in high-risk operations.

Prior to this, dexterous hands developed by the Japan Electric Laboratory or Stanford University in the United States featured a three-finger structure. While the three-finger solution offers advantages due to fewer driving units and simpler control algorithms, the four-finger solution is irreplaceable in terms of functional coverage and bionic efficiency:

- Functional Completeness: The four-finger structure supports complex combined operations, like "tearing labels + scanning codes," difficult to achieve with a three-finger solution.

- Fault Tolerance Redundancy: When a single finger fails, at least 30% of operating capability can still be retained, with the fault tolerance rate of the three-finger solution nearing zero.

- Cost Efficiency: Compared to a five-finger hand, it saves 20% of hardware costs and provides 40% more functional coverage than a three-finger hand.

- Structural Optimization: Among the 21 degrees of freedom in the human palm, the little finger contributes less than 5%. Removing it has no impact on most tasks but simplifies structural design.

At the academic level, the team led by Liu Hong from the Harbin Institute of Technology has experimentally proven that four-finger hands can perform high-precision tasks requiring tactile feedback, such as playing the piano and grasping eggs. The research products even surpass human hands in temperature and force sensing capabilities.

Ding Ning, Executive Vice President of the Shenzhen Institute of Artificial Intelligence and Robotics, also believes that a robot's hand does not necessarily need five fingers like a human hand. Three fingers can already meet task execution needs, with an extra finger serving as a backup.

Currently, the most notable four-finger dexterous hand products on the market are DexH13 and DexH5 by Paxini Technology. DexH13 is the world's first multidimensional tactile + AI vision dexterous hand.

Initially adopting a five-finger design, Paxini switched to a four-finger design after discovering that 85% of scenarios could be completed with just four fingers, directly reducing hardware costs by 20%.

Paxini is one of the few domestic enterprises with independently controllable core technology for high-precision multidimensional tactile sensors. Based on a 6D Hall array tactile sensor, it has built a full-stack product matrix from "core sensors - dexterous hands - humanoid robots."

DexH13 is Paxini's second-generation dexterous hand, with a core technology centered around a high-density tactile sensing system. It has 16 degrees of freedom, a maximum load of 5kg, and a lifespan of 1 million cycles. Each hand integrates 1,140 ITPU sensors, capable of simultaneously analyzing 15 physical parameters like pressure, friction, surface texture, and temperature, achieving high-precision measurement of 0.01N across the full range. It is also equipped with an 8-megapixel high-definition AI hand-eye camera, priced at 98,000 yuan.

DexH5 has 9 degrees of freedom, a maximum load of 4kg, integrates 528 ITPU sensors per hand, and has a force control accuracy of 0.1N, making it more lightweight than the second generation.

Equipped with the DexH13 dexterous hand, Paxini's self-developed wheeled robot TORA-ONE has been used to assist doctors in delicate surgeries in hospitals and high-precision assembly tasks in factories.

Five-Finger: The Anthropomorphic Universal Choice

Dexterous hands are essentially a product of humans balancing the "anthropomorphism" and "functionalization" of machinery. As masters of the physical world, human hands have evolved for millions of years, with the bone-tendon-nerve coordination mode of the five fingers achieving a balance between flexibility, load efficiency, and energy consumption.

Driven by the initial intention to mimic the flexibility and perception capabilities of human hands, enabling robots to perform complex manipulation tasks, most dexterous hands have opted for a five-finger design akin to human hands, avoiding the costs of redesigning and verifying.

From a functional adaptability perspective, the human hand has 21 degrees of freedom and weighs only about 0.4 kilograms but undertakes 54% of the body's motor functions, enabling actions like fine grasping and tool manipulation. The five-finger structure supports "omnidirectional opposing finger space," enabling diversified actions such as grasping, pinching, twisting, and lifting, covering 99% of daily operation needs.

From a structural design perspective, while three-finger dexterous hands offer cost or structural advantages in specific scenarios, they have limitations in operational diversity and adaptability. Although the four-finger structure is functionally closer to the human hand, it struggles to fully replicate the opposition function of the thumb.

This functional deficiency becomes particularly apparent in scenarios that require precise manipulation or tool usage. Conversely, the five-finger configuration excels in functional completeness, offering ample design flexibility for tactile, force, and temperature sensors.

Unlike the fixed-path operations of industrial robotic arms, dexterous hands must adapt to the shapes of objects in unstructured environments. The distributed contact points of five fingers enable a force-closed grip, ensuring stability even if one finger loses contact.

Moreover, from a human-machine interaction perspective, the five-finger design aligns with humans' cognitive framework of "hands," fostering a sense of identity and emotional trust.

Currently, the domestic landscape of five-finger dexterous hand technology is diverse, with various players adopting distinct solutions and no clear convergence trend. Mature products utilizing direct motor drive, linkage transmission, and tendon drive solutions are available.

Star Motion Epoch's XHAND1 employs a direct motor drive approach, boasting 12 degrees of freedom and a maximum load capacity of 25kg. It features a fully proprietary integrated joint module.

The five fingertips of XHAND1 are equipped with high-precision, high-resolution tactile sensor arrays, capable of detecting forces as low as 0.05N, providing sensations of contact, sliding, and temperature.

Its newly released full-sized bipedal humanoid robot, L7, equipped with XHAND1, excels in tasks such as cocktail making, sorting, scanning, handling, and assembly.

InTime Robotics, a vendor adopting the linkage solution, showcased its fifth-generation product, the RH56F1 series of humanoid five-finger dexterous hands, at the recent WAIC. Positioned as "dexterous hands that understand robots better," these hands have a static load capacity of 30kg and a fingertip gripping force of 15N.

The RH56F1 series features a proprietary concealed internal wiring solution, addressing the wear and interference issues associated with exposed cables in traditional dexterous hands, thereby extending the product's lifespan. Additionally, it integrates 24 sets of sensors across four categories—touch, force, position, and temperature—enabling multimodal fusion perception. Prior to this, InTime Robotics had launched the RH56BFX, RH56DFX, RH56E2, and other series of dexterous hands.

In 2024, InTime Robotics shipped nearly 2,000 dexterous hands, and sales surpassed 4,000 units in the first half of 2025, solidifying its position as the domestic leader in dexterous hand shipments. The company aims to reach 10,000 shipments this year.

In China, besides LingQiao Intelligent, LingXinQiaoShou is another representative vendor adopting the tendon drive solution. It is the only domestic company capable of mass-producing dexterous hands with direct drive, linkage, and tendon drive transmission structures simultaneously.

Its flagship product, the high-degree-of-freedom dexterous hand Linker Hand L30, combines tendon and linkage technologies, offering 42 degrees of freedom at a price of 99,000 yuan. Each finger of the Linker Hand L30 can independently achieve 9 degrees of freedom motion control and features a 360-degree freely rotating full-drive design.

This dexterous hand can perform complex actions like pen spinning and walnut rotating, with a load capacity of 5kg, surpassing human finger limits. LingXinQiaoShou anticipates shipping approximately 5,000 units this year, ranking among the industry leaders in shipments.

No single design offers a perfect, ultimate solution; the key is to align with the needs of the specific scenario.

From the pursuit of a "form-similar" three-finger solution to a four-finger balance of redundancy and coverage, to a five-finger approach striving for "spirit-similar" functionality, the evolution of dexterous hands clearly demonstrates the deep coupling between technical rationality and scenario demands.

Regardless of the chosen solution, the ultimate goal remains the same: to seamlessly integrate machines' "hands" into the physical world, efficiently and reliably fulfilling human-assigned tasks.