Sony's Exit: Deflating the 'Prosperity Bubble' in China's Optics Sector

![]() 12/19 2025

12/19 2025

![]() 638

638

Recently, following the closure of Canon's Zhongshan plant by a Japanese conglomerate, Sony has also declared its intention to pull out of its Huizhou factory in China. Industry insiders have revealed that Sony divested its stake in Sony Precision Components (Huizhou) Co., Ltd. to RS Technologies, a Japanese recycled wafer manufacturer, at the end of December last year.

Significantly, the optical pickup head production at Sony's Huizhou plant once commanded a 45% share of the global market and stood as the world's premier production hub for optical pickups.

The plant's closure symbolizes a pivotal moment in the restructuring of the global optical industry chain, highlighting the profound shifts occurring in the global optics sector amidst technological upheavals and geopolitical strains.

Reflecting on the history of Sony's Huizhou plant, it commenced operations during the heyday of optical storage. The optical pickups it manufactured were vital components in CD, DVD, and Blu-ray players, acting as the 'optical heart' of digital content in that era. As streaming services revolutionized content distribution, the market for physical optical discs plummeted, causing the industry chain that supported its 'heart' to crumble.

This equity transfer marks the formal disengagement of optical pickups from Sony's portfolio, with Sony finalizing its strategic exit from declining businesses. The acquisition by RS Technologies, a Japanese upstream semiconductor firm, unveils the destination of this divestiture—the value peaks of optical precision manufacturing are swiftly merging into the semiconductor and high-end equipment manufacturing sectors from consumer electronics.

RS Technologies' core business revolves around recycled wafers. It is uninterested in the dwindling optical pickup market, focusing instead on the decades of accumulated expertise in ultra-precision machining, nanoscale clean assembly, and large-scale precision manufacturing control at the Huizhou plant. These capabilities are precisely the scarce resources needed for manufacturing critical components in semiconductor equipment, such as optical inspection systems, photolithography machine parts, and wafer transfer mechanisms.

Simultaneously, amid escalating competition in high-end manufacturing and mounting geopolitical uncertainties, Japanese companies are more prone to circulating core technologies and precision manufacturing capabilities within domestic firms, indicating that supply chain security considerations have superseded purely globalization-driven cost considerations.

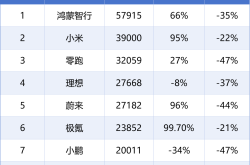

Sony's departure leaves not only vacant factories but also poses a significant challenge. China has spawned consumer optics behemoths like Sunny Optical and O-Film, which dominate the global market in mobile phone lens modules. However, this prosperity is largely predicated on large-scale assembly integration and rapid market application iteration. Domains that dictate the upper echelons of optical performance, such as high-end optical glass, specialized optical resins, coating materials, precision CNC and aspherical machining equipment, and aberration design software, still heavily depend on imports.

The relocation of Sony's Huizhou plant and the prior shutdown of Canon's Zhongshan plant, the world's largest production base for black-and-white laser printers and dubbed the 'Asian Optics Factory,' are not isolated incidents but mirror the same industrial cycle. This also signals that the value chain of the global optics industry is fragmenting, reorganizing, and re-welding, and China's optics sector must undergo a painful metamorphosis from being a 'value appendage' to a 'value originator'.

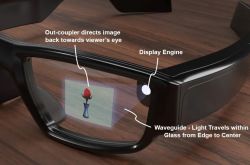

Looking ahead, Chinese optics firms must ascend the value chain, establishing autonomous core capabilities and ecosystems in new value peaks such as optical materials, precision optical instruments, semiconductor inspection equipment, and LiDAR optical systems, to construct a genuine value stronghold for Chinese manufacturing.