What Impact Will Embodied Intelligence Have on the Collaborative Robot Industry?

![]() 11/13 2025

11/13 2025

![]() 465

465

Produced by Zhineng Technology

As a vital carrier of embodied intelligence, collaborative robots are emerging as a key bridge connecting artificial intelligence (AI) with the real economy. By 2025, with breakthroughs in core technologies such as perception, control, and algorithms, collaborative robots are set to accelerate into a phase of large-scale application.

Chinese enterprises are making their mark on the global industrial stage, thanks to their independent control over upstream core components and innovative capabilities in midstream products. Meanwhile, the dual momentum from industrial and non-industrial scenarios is driving collaborative robots to evolve from "automation tools" into "intelligent partners."

01

Embodied Intelligence: Redefining the Role of Collaborative Robots

Embodied intelligence represents the transition of AI from virtual spaces to the physical world. Intelligence cannot exist independently of the body; its formation and evolution must integrate perception and action. Collaborative robots are the most direct manifestation of this concept, capable of perceiving their external environments and interacting safely and naturally with humans, becoming "intelligent entities with a body."

In traditional AI systems, algorithms often remain at the "cognitive level," unable to effectively handle complex physical scenarios.

Collaborative robots, however, establish a closed loop of "perception-decision-action-feedback" through integrated perception systems, control algorithms, and dynamic design.

For instance, JAKA Robotics' integrated joint technology combines motors, encoders, and drive systems into a highly integrated unit, enabling robots with high-density, low-power motion capabilities. This provides crucial support for embodied intelligence carriers like humanoid robots, reducing body weight while enhancing dynamic response speed. As a result, collaborative robots can perform high-precision tasks in more complex environments.

The definition of collaborative robots is also evolving. Early industrial robots were confined to fixed, enclosed work areas, performing specific tasks with high speed and repeatability.

Collaborative robots, through hardware-software integration, break the traditional paradigm of "human-machine separation."

Their core value lies in three aspects: safety, flexibility, and ease of use.

◎ Safety is ensured by international standards like ISO/TS 15066, which require collaborative robots to automatically detect collisions and decelerate or stop instantly in fenceless environments. Leading models now achieve collision detection accuracy of ±0.05 mm, sensing force changes upon contact.

◎ Flexibility is demonstrated through modular design and "drag-and-teach" functionality, allowing operators to directly guide the robotic arm for path demonstration, which the robot can then replicate.

◎ Ease of use is enhanced by integrating AI algorithms and voice interaction, enabling non-professionals to complete task programming within 20 minutes, truly achieving "robots understanding human language."

This "human-machine symbiosis" model, centered on embodied intelligence, expands the role of collaborative robots beyond industrial manufacturing to become a universal platform for multiple scenarios.

From workshop assembly to catering services, from laboratory testing to educational training, collaborative robots are gradually integrating into the daily operations of human society as "flexible intelligent entities."

02

Coordinated Evolution: Localization, Autonomy, and Intelligence

The collaborative robot industry in 2025 is undergoing dual transformations in technology and supply chains. The localization rate of upstream components exceeds 90%, midstream manufacturers are transitioning towards embodied intelligence platforms, and downstream applications are expanding from industrial manufacturing to lifestyle services. This forms a complete industrial logic of "autonomous control-intelligent upgrade-scenario explosion."

● Upstream Sector: From "Addressing Shortcomings" to "Leading the Pack"

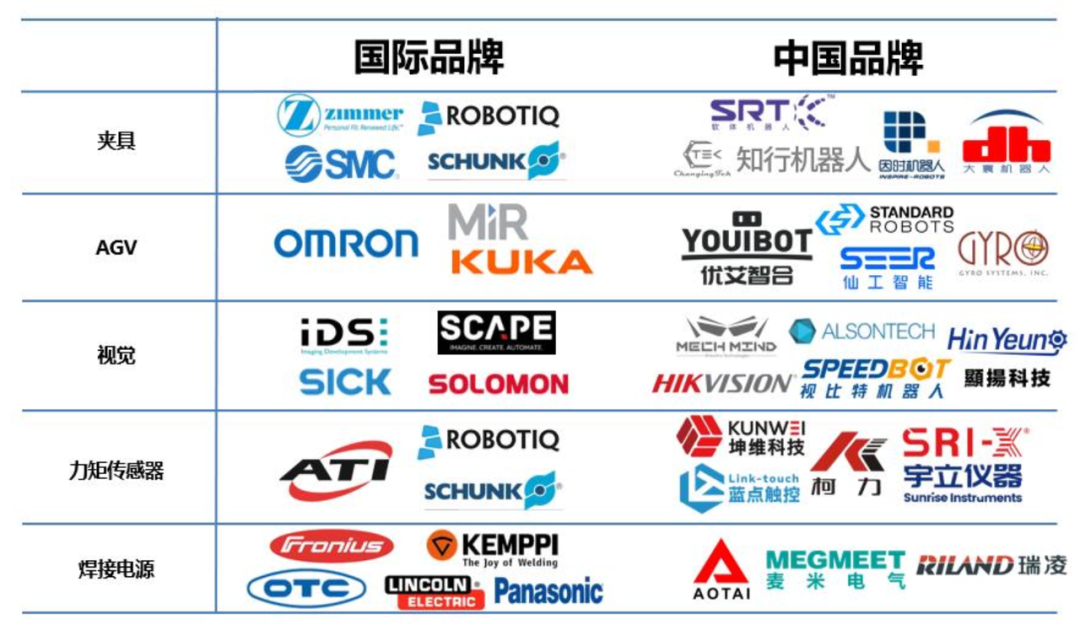

In the cost structure of collaborative robot bodies, controllers, servo systems, and reducers account for up to 70% of the core components. Previously dominated by Japanese and European firms, Chinese manufacturers have now fully broken this dependence.

◎ Companies like JAKA and AUBOT have adopted the ROS 2 architecture in controllers, developing highly open control systems suitable for non-standard scenarios like healthcare and education.

◎ In servo systems, Inovance Technology and Hechuang Technology's drivers now approach international standards, with some models surpassing imported brands in response speed and anti-interference capabilities.

◎ Reducers from LD Harmonic Drive and Laifu Harmonic Drive meet international precision standards, enabling domestic collaborative robot manufacturers to achieve 100% localization of reducers, reducing unit costs by approximately 30%.

Chinese collaborative robots now possess the capability to evolve from "autonomous production" to "autonomous optimization." The technological closed loop in component manufacturing not only mitigates supply chain risks but also provides data and hardware foundations for subsequent localized optimization of intelligent algorithms.

● Midstream Sector: Embodied Intelligence as Core Product Competitiveness

Currently, two distinct innovation paths have emerged in the industry.

◎ One path, taken by JAKA, AUBOT, and other collaborative robot specialists, focuses on AI algorithms and multimodal perception as breakthroughs. They have launched platforms like JAKA EVO that integrate vision, voice, and force control, enabling robots with self-learning and self-calibration capabilities.

◎ The other path involves traditional industrial robot giants like ABB and FANUC, which are actively participating in intelligent manufacturing upgrades by introducing high-speed, specialized collaborative models.

For example, ABB's PoWa series collaborative robots optimize micro-welding and rapid assembly tasks for the electronics industry, while FANUC's explosion-proof CRX-10iA/L Paint enters the automotive painting field, achieving higher safety and environmental adaptability.

● Downstream Sector: Expansion from "Factories" to "Lifestyle"

The applications of collaborative robots are breaking through traditional industrial boundaries.

◎ In 2024, the penetration of collaborative robots in China's automotive, electronics, and metal products sectors continued to rise, with heavy-duty models growing fastest in automotive assembly and palletizing.

◎ Simultaneously, non-industrial sectors have become new growth poles: healthcare leverages collaborative robots for automated sample detection and delivery; education establishes flexible manufacturing-based training platforms; in catering and retail, dual-arm coffee robots and intelligent meal distribution systems have achieved commercialization.

JAKA's coffee robot project deployed in Indonesia even boosted store orders by 20%, validating the efficient substitution potential of robots in the service industry. Collaborative robots are not only serving as production tools but also becoming part of the intelligent social infrastructure.

The global collaborative robot market is transitioning from early European and American dominance to a multi-polar competition landscape of "Chinese industrial chain leadership and parallel technological innovations from multiple countries." In 2024, global collaborative robot sales reached 68,000 units, a 25% year-on-year increase; it is projected to exceed 100,000 units in 2025, with market growth continuing above 40%.

The Chinese market has become the core driver of global growth.

In 2024, China's collaborative robot sales reached approximately 30,000 units, accounting for 44% of the global market, with manufacturers like JAKA, AUBOT, and Huayan occupying over 60% of the domestic share. JAKA, with its overseas channel layout, has entered the supply chains of automakers like Toyota and Tesla, ranking among the top three globally.

In contrast, European and American markets remain concentrated in high-end manufacturing and aerospace, while Japanese and Korean firms maintain leadership in electronics and shipbuilding.

Among the top five global manufacturers, Chinese companies now occupy three seats, marking a fundamental shift in the industry's competitive landscape.

Universal Robots (UR) still holds the global top spot, but its new models UR7e and UR12e have been deeply customized for Chinese users, reflecting international manufacturers' emphasis on the Chinese market.

Meanwhile, South Korean firm Neuromeca has secured investment from POSCO Holdings with its AI force control algorithms, focusing on shipbuilding welding and intelligent manufacturing systems, collaborating with HD Hyundai and others to build a new-generation AI manufacturing ecosystem.

The core competitiveness of collaborative robots still stems from underlying algorithms and system integration.

Current technological breakthroughs focus on three areas: motion control, force control algorithms, and multimodal perception.

◎ In motion control, path planning and dynamic replanning algorithms based on Cartesian space enable robots to perform complex trajectory operations with millimeter-level precision.

◎ Force control algorithms simulate human muscle flexibility through impedance control, achieving dual-precision control of "force and position" in tasks like assembly and welding.

◎ Multimodal perception integrates 3D vision, six-dimensional force control, and LiDAR for environmental modeling and real-time obstacle avoidance, enabling robots to complete "autonomous grasping-delivery" tasks in dynamic scenarios.

Summary

In 2025, the collaborative robot industry will enter a new stage of "embodied intelligence," with full localization of the industrial chain. The localization rate of upstream key components exceeds 90%; midstream products evolve towards AI integration and platformization, forming intelligent systems with multimodal perception; application scenarios expand from industrial to non-industrial settings, achieving multi-layered penetration into an intelligent society.