Hikvision Assists Zijin Mining in the Digital Transformation of the Entire Production Chain!

![]() 06/18 2024

06/18 2024

![]() 560

560

On the snow plateau with an altitude of over 5,400 meters, the intelligent weighbridge system is automatically weighing, and the entire process is unattended; in the power distribution room, industrial auscultation equipment uses audio algorithms to detect equipment status in real-time and identify abnormal noises; by opening the safety "one map", the operation status of each production unit is intelligently managed, ensuring the safe operation of front-line production... In Zijin Mining Group, more and more intelligent equipment and innovative means are being integrated into all areas and processes of production.

In recent years, Zijin Mining Group has conducted in-depth strategic cooperation with Hikvision, actively exploring digital transformation in the entire production chain including geological exploration, mining, beneficiation, metallurgy, and environmental protection, achieving safe production, cost reduction, and efficiency enhancement. As intelligent IoT technology meets mines, digital scenarios continue to "update," and the non-ferrous metals industry is undergoing a digital and intelligent transformation.

Remote supervision of mining and beneficiation digitization assists in the safe operation of front-line production

Zijinshan Copper and Gold Mine, a subsidiary of Zijin Mining Group, was awarded the honorary title of "China's Largest Gold Mine" by the China Gold Association, and safe production has always been a top priority. In the centralized control center of Zijinshan Copper and Gold Mine, Hikvision's intelligent IoT technology helps create an AR real-scene map, where real-time production images, vehicle entry and exit, safe operation management, tailings dam sensor collection, and other various safe production data are clearly visible at a glance. The centralized control center manages each production unit through the safety "one map," achieving linkage collaboration, intelligent management, and ensuring the safe operation of front-line production.

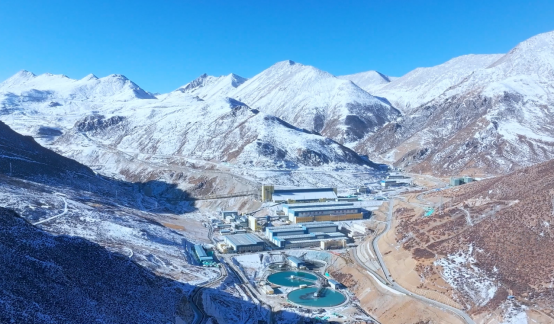

On the other side of the vast land, the Tibet Junlong Copper Mine, which also belongs to Zijin Mining Group, is located on a snow plateau with an altitude of over 5,400 meters and an oxygen content of only 14%. The thin air and large temperature difference between day and night cause altitude sickness and common altitude-related illnesses that plague the stationed management and construction personnel. How to leverage the power of intelligent equipment becomes particularly important.

Through Hikvision's dual-spectrum heavy-duty pan-tilt camera, laser heavy-duty pan-tilt camera, low-light camera, and other equipment, the Junlong Copper Mine allows management personnel to grasp the mining and beneficiation situation on-site in real-time from the centralized control center, achieving remote supervision. At the production site, an intelligent weighbridge system is created through smart devices such as license plate recognition and detection measurement, achieving unattended operation throughout the weighing process; the mine vehicle speed measurement system effectively curbs speeding and other违规行为, reducing the risk of vehicle accidents.

Figure: The intelligent weighbridge system achieves unattended operation throughout the weighing process

With Zijin Mining's global layout, the Bor Copper Mine in Serbia, located far away in Europe, has also been assisted by Hikvision in building a visualized unified management platform and a modern centralized control center, improving the mine's safety management level.

AI Empowers Metallurgical Production, and Digital Products Assist in Improving Production and Management Efficiency

Digital changes are also taking place in the metallurgical process. At Zijin Copper, video AI detection has covered multiple scenarios from train number identification in the cargo transportation process, temperature detection and warning of electrolytic cells in the production workshop, equipment inspections, and safety precautions during overhead crane operation. Through real-time intelligent analysis and timely risk warnings, the quality and efficiency of safety monitoring are significantly improved, helping to reduce production safety risks and empower the upgrading of safety supervision with intelligent IoT.

In the Zijin Copper Foil production workshop, AGV robots work orderly and seamlessly integrate with the production line, greatly improving production efficiency and the company's intelligent manufacturing level; in the power distribution room, industrial auscultation equipment uses audio algorithms to detect equipment status in real-time, identify abnormal noises, and simultaneously connects hazard data to the enterprise's safe production management platform through a smart gateway, breaking data silos between different systems and achieving unified management; in the park, intelligent applications such as vehicle management systems, full-scenario digital attendance systems, and cafeteria consumption systems serve daily management, effectively enhancing the park's digital management level.

Figure: Industrial auscultation equipment uses audio algorithms to detect equipment status in real-time

Intelligent IoT Technology Assists Environmental Protection and Promotes the Development of Green and High-Quality Ecological Mines

Zijin Mining has always adhered to the ecological and environmental protection philosophy of "lucid waters and lush mountains are invaluable assets" and the principle of "giving equal importance to the development and protection of mineral resources," creating green mines with global high standards while actively introducing technology to assist in environmental protection. Hikvision's intelligent IoT technology has also joined Zijin Mining's environmental protection efforts. Smart IoT equipment located at sewage outlets can assist in real-time data collection and online monitoring of pollution sources, helping Zijin Mining comprehensively promote the development of green and high-quality ecological mines.

"The current wave of digital transformation is driving the industry towards green, safe, and efficient transformation," said Dong Wensheng, Information Director of Zijin Mining Group and General Manager of Zijin Zhixin. "Zijin Mining has joined forces with Hikvision to promote digital transformation, utilizing intelligent IoT technology to optimize business processes, build 'smart mines' and 'intelligent factories,' achieve cost reduction, efficiency enhancement, and safe production, and promote the efficient operation of the group's globalization."

Digitization and intelligence are not only the inherent needs of mining enterprises but also the general trend of industry development. Zijin Mining has evolved from a single visualization method to comprehensive perception, data aggregation and analysis, and unified management of IoT information in various scenarios of production and parks. This is a microcosm of the digitalization and intelligent evolution of the non-ferrous metals industry. Under the wave of digitization, technology companies such as Hikvision are also continuously innovating in the OT (Operational Technology) field, providing numerous scenario-specific digital products and solutions for the non-ferrous metals industry, promoting the accelerated digital transformation of the industry.