The Spurned 'Leader in Humanoid Robots': Where Did Boston Dynamics Go Wrong?

![]() 01/14 2026

01/14 2026

![]() 405

405

Is this your attitude of admitting mistakes?

At the recently concluded CES 2026, Boston Dynamics, dubbed the 'leader in humanoid robots,' made a watershed choice—officially abandoning its long-criticized hydraulic system, deemed both 'unimpressive and impractical,' and fully transitioning Atlas to electric drive. This shift is not merely an engineering change but a pivotal step for Boston Dynamics to shed its labels of 'technological showmanship' and 'engineering PPT,' moving decisively toward scalability and industrialization.

During the live demonstration, Boston Dynamics highlighted that the new Atlas features highly human-like movements, with natural, smooth, and seamless actions. Its design draws inspiration from the human body structure but surpasses human physiological limits in flexibility, stability, and extreme motion range. Industry insiders consider Atlas the most capable and technically mature humanoid robot among those publicly disclosed.

More importantly, the market's perception of Atlas's ultimate positioning is undergoing a qualitative shift. A growing consensus suggests that Atlas is not designed for a single vertical role but aims for the 'general labor' endgame. Through continuous training with AI large models, robots can acquire operational capabilities far beyond human experience and replicate new skills in a 'software-like manner' across other units. Against the backdrop of a persistent global labor shortage, this positions robots as scalable production factors.

If Boston Dynamics previously demonstrated the 'extreme motions humanoid robots can achieve,' the all-electric Atlas marks its entry into a more dangerous yet realistic proposition: When machines can not only move and learn but also be replicated and scaled, how will human society redefine 'work' itself?

01 The Final Hurdle for Humanoid Robots: Dexterous Hands Fall Short

Before discussing how humans should redefine work, humanoid robots must overcome a critical barrier: genuinely replacing human labor.

Among all technical challenges, the last and most difficult hurdle is not walking, balance, or even cognition but whether humanoid robots can possess truly 'human-like hands.'

At CES 2026, Boston Dynamics' Atlas featured only three fingers; other public videos showed a four-finger version. Across the industry, some manufacturers have experimented with five-finger humanoid robots, which initially appear more 'human-like.' However, a counterintuitive truth emerges: More fingers do not equate to more human-like functionality; in fact, greater human-like appearance often reduces practicality.

Even Atlas, a leader in the field, has avoided fully replicating human hands. Some argue this is not a technological limitation but an engineering trade-off.

Human hands, the product of millions of years of evolution, boast extreme degrees of freedom, complex tendon structures, and highly refined force feedback systems. For robots, each additional finger exponentially increases control complexity, computational demands, sensing intricacy, and failure risks.

In other words, creating a 'human-looking' robotic hand is not difficult; the challenge lies in building one that can reliably and consistently perform tasks. Rather than pursuing morphological similarity, manufacturers should prioritize reliability, controllability, and error prevention in unpredictable physical environments.

This explains why today's humanoid robots can run, jump, and lift but still struggle with seemingly simple tasks like screwing, cable management, or grasping flexible objects. The issue lies not in machine intelligence but in the profound complexity of the human hand—an underrated marvel.

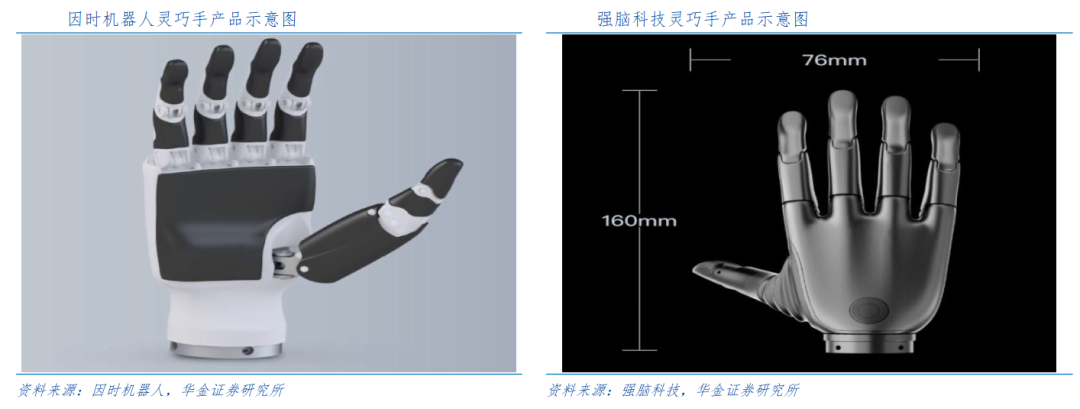

Against this backdrop, manufacturers are increasingly investing in dexterous hands. Original equipment manufacturers (OEMs) like Tesla, Unitree, and UBTECH are developing in-house solutions, while component suppliers such as Starry Dynamics, Magic Atom, Dexterity Intelligence, and Intime Robotics are creating various dexterous hand products.

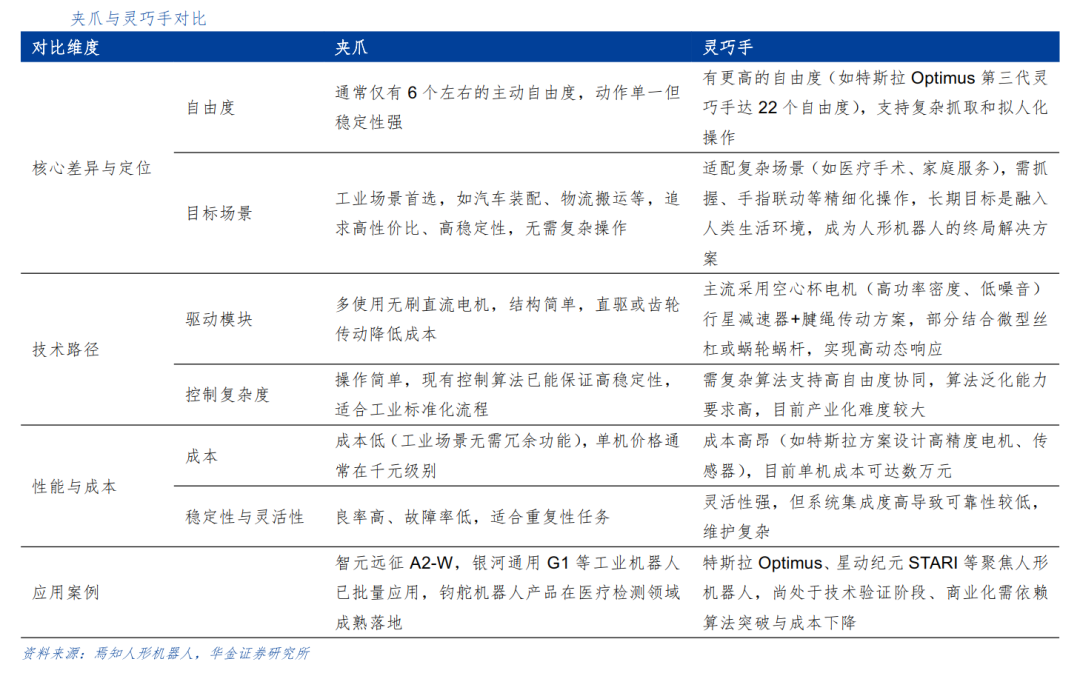

Traditional grippers or holding hands have found applications in industrial assembly and medical testing but suffer from limited generalization due to their standardized design. Dexterous hands, with their human-like structure, high degrees of freedom, and precision, can perform complex tasks such as grasping small objects and handling items. They hold significant potential across industrial, commercial, and domestic settings.

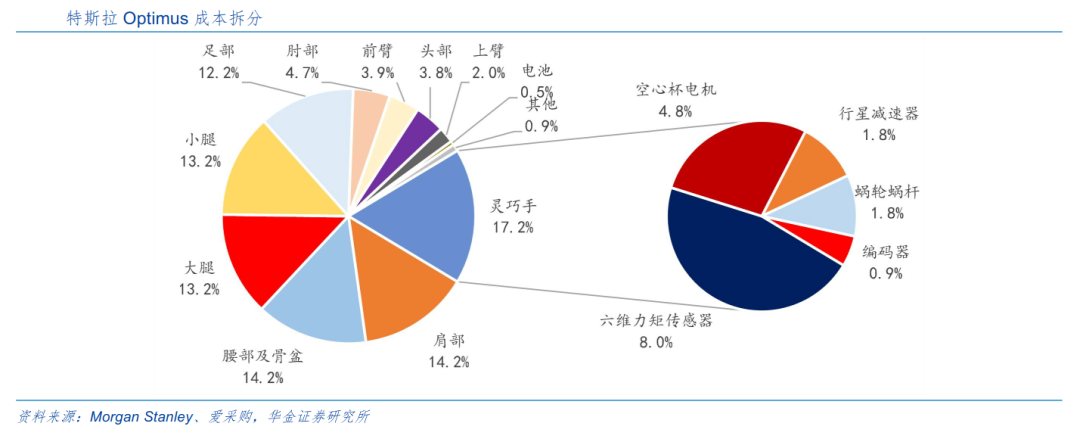

Cost-wise, dexterous hands account for approximately 17% of a robot's total cost, making them one of the most critical components. Taking Tesla's Optimus as an example, a cost breakdown reveals that dexterous hands constitute the largest share at 17.2%, with core components including coreless motors (4.8%) and six-axis force sensors (8.0%). Planetary gearboxes, worm gears, and encoders account for 1.8%, 1.8%, and 0.9%, respectively. Coreless motors and six-axis force sensors are the most vital parts of dexterous hands.

Atlas's shift from hydraulic to electric systems has led some to believe that hydraulics are obsolete in humanoid robots due to the superiority of electric motors. However, the truth is the opposite: Hydraulics are not inadequate but ill-suited for the task. Hydraulics excel in explosive power and extreme motions but struggle in prolonged, stable, and replicable work environments.

Once deployed in factories and urban settings, the complex maintenance and unpredictable control of hydraulic systems become magnified. Critically, hydraulics are incompatible with AI learning, whereas electric motors serve as standardized interfaces ideal for model training. Hydraulics belong to the engineer's era; electric motors, to the algorithm's age.

02 Electric Motors: The Preferred Choice for Dexterous Hands

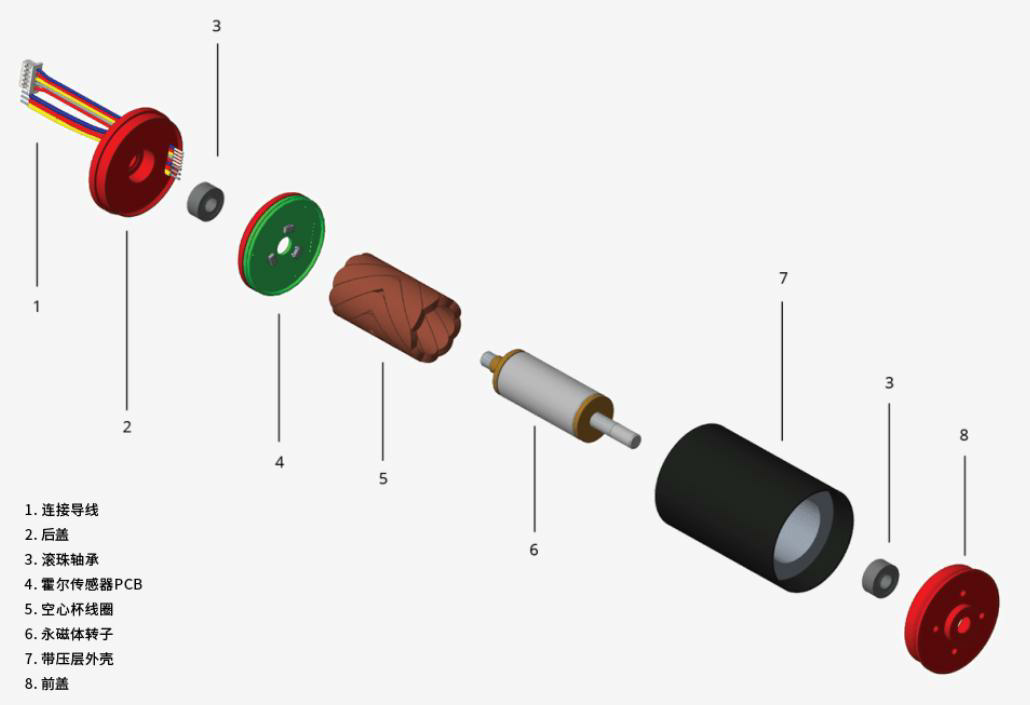

Motor-driven systems meet the demands of humanoid robot dexterous hands and have become the mainstream solution. These systems integrate coreless motors, brushless slotted motors, and gearboxes, offering advantages such as compact size, rapid response, easy control, and stable torque output, making them widely applicable in dexterous hand control.

Compared to traditional motors, coreless motors feature ironless rotor designs that eliminate eddy current effects—a source of heating, torque fluctuations, and energy loss during operation. Given the high degrees of freedom, precision, and rapid response requirements of dexterous hands, coreless motors have become the dominant choice due to their compact size, high precision, and lightweight nature.

Source: Shenzhen Zhengyuan Motor Co., Ltd. official website, Huajin Securities Research Institute

Comparing brushed and brushless motors, brushless motors offer longer lifespans due to the absence of mechanical brushes, reducing wear and tear. This makes them more durable, especially in high-speed operations and harsh environments, while also operating more quietly. Additionally, brushless motors achieve higher rotational speeds, superior conversion efficiency, and better control performance.

In contrast, hydraulic-driven dexterous hands consist of hydraulic motors, servo valves, pumps, and tanks, typically used in industrial settings. Hydraulic systems provide substantial gripping force for large loads but face challenges in miniaturization and portability.

Pneumatic systems use gas as a medium to mimic human muscle actuation, offering advantages like easy control, convenient energy storage, and system flexibility. However, their low stiffness, poor dynamic performance, assembly complexity, and imprecise motion limit widespread industrial adoption, restricting them to simple grippers incapable of multi-joint flexibility.

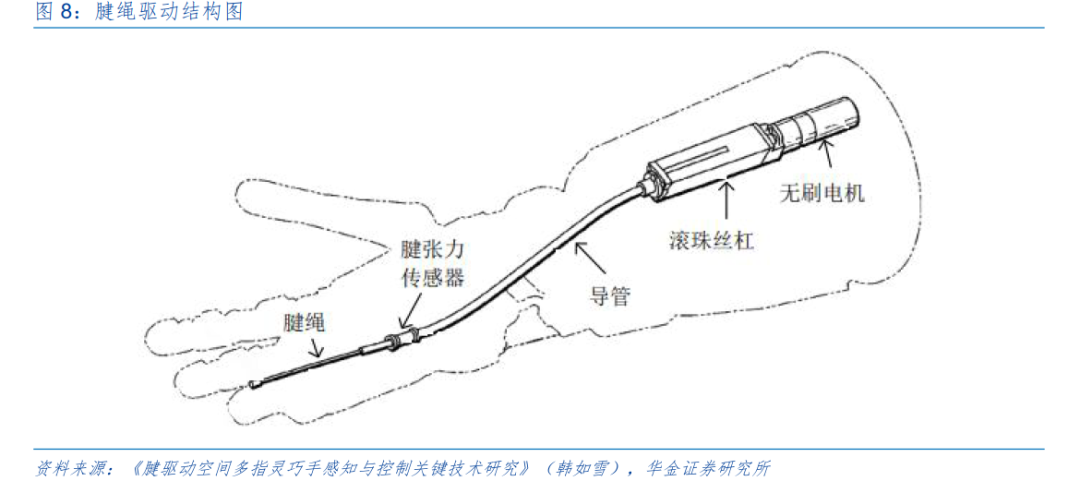

In transmission, tendon-driven systems enable remote power transfer. Motors in the forearm drive ball screws via gearboxes, converting rotational motion into linear motion through nuts. Tendons form loops around these nuts, which pull on tendons connected to finger phalanges, enabling rotational movement around joint axes.

Tendon-driven systems mimic human tendon distribution, using materials and sheaths or sleeves to route tendons flexibly within the arm, palm, and fingers. This compact structure with elasticity provides smoothness and gripping adaptability for finger motion, enabling remote power transmission.

Tendon-driven systems offer diverse structures due to flexible routing, including tendon-sheath, equal-diameter pulley, and belt-driven designs. Their high flexibility and compact size reduce structural demands on actuators and gearboxes.

Currently, the humanoid robot industry lacks a unified technical approach for dexterous hands. Tendon, linkage, and gear transmission schemes each have trade-offs in control precision, structural complexity, cost, and reliability, leading to parallel adoption by mainstream OEMs.

03 Who Makes the Best Dexterous Hands?

With technical routes still divergent, dexterous hands have not standardized like motors or gearboxes. Instead, they foster specialized manufacturers deeply invested in distinct technical paths.

These firms avoid direct competition in robot assembly, instead leveraging expertise in transmission systems, control algorithms, or sensor integration to become indispensable partners for OEMs in enhancing 'last-centimeter' capabilities. Dexterous hand vendors, following varied technical routes, serve as critical indicators of the humanoid robot industry's differentiation and maturity.

Some OEMs develop dexterous hands in-house, iterating toward higher degrees of freedom and stronger sensing to expand applications. For instance, Tesla's Optimus evolved from 11 to 22 degrees of freedom, progressing from basic to complex tasks like catching tennis balls. Unitree's DEX3-1 had 7 degrees of freedom, while the DEX5-1 reached 20, significantly boosting potential.

Beyond Tesla and Unitree, UBTECH's Walker S2 features an 11-degree-of-freedom dexterous hand with six array-type tactile pressure sensors. Its lightweight, high-strength design enables sub-millimeter precision and lifting 15 kg across a 0–1.8 m range, meeting industrial handling demands.

Source: UBTECH official website

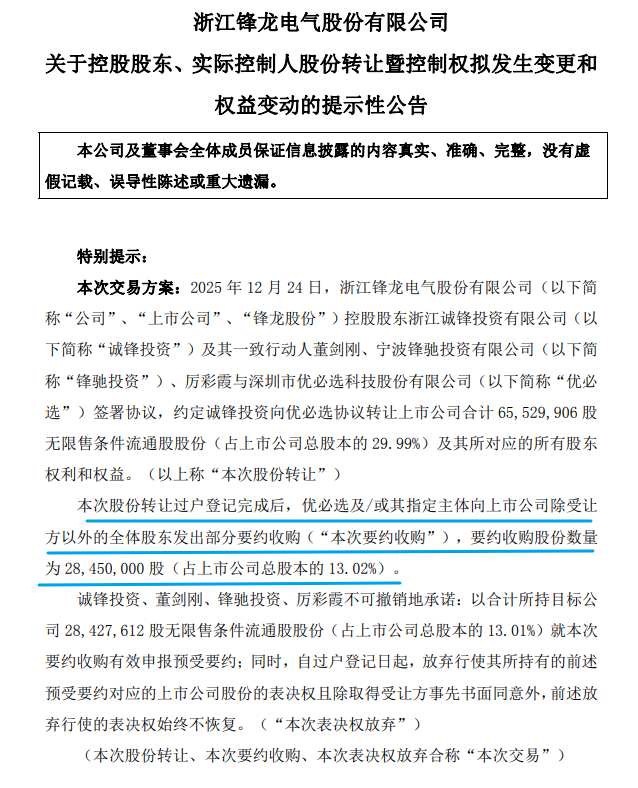

Supported by advanced products, UBTECH gradually entered the secondary market. According to Fenglong's December 25 announcements, its controlling shareholder changed to UBTECH.

Besides OEMs, numerous component suppliers focus on dexterous hands. Intime Robotics offers end effectors like the RH56BFX, RH56DFX, and RH56E2 series dexterous hands, along with EG2-4B and EG2-4C servo electric grippers. The RH56DFX, a human-like five-finger hand, delivers 1.5 kg single-finger gripping force, ±0.2 mm repeatability, 0.5 N force resolution, and weighs just 540 g. It handles eggs, fruits, barbells, cups, and tools, meeting precision task demands.

Once dexterous hands match or surpass human capabilities, the humanoid robot industry will transform. Robots will transition from 'advanced equipment' to bona fide general labor, reliably performing gripping, assembly, sorting, and maintenance tasks. Business models will shift from selling machines to charging by time, task, or skill. The market's ceiling will no longer depend on equipment demand but on the global labor shortage.

Critically, when hand capabilities cease to be a bottleneck, industry competition will pivot from hardware manufacturing to skill training, data accumulation, and cross-scenario replication efficiency. The ability to rapidly train and deploy operational skills across thousands of robots will determine new productivity allocation rights. Humanoid robots will evolve from products into schedulable, subscription-based 'work capabilities.'

Conclusion

Viewing Atlas as merely a more advanced humanoid robot underestimates its disruptive potential for automotive and manufacturing industries. For these sectors, Atlas represents a 'mobile, learnable, and replicable general workstation' rather than a traditional equipment upgrade.

In the automotive manufacturing system, what has truly plagued automakers in the long run has never been a shortage of robotic arms, but rather the numerous 'non-standard processes' that are highly reliant on manual labor—flexible assembly, exception handling, temporary line changes, and cross-station collaboration. These scenarios are difficult to fully automate and continuously drive up labor costs and management complexity. The emergence of Atlas means that these processes, which in the past could only rely on the 'experience of skilled workers,' now have the potential to be taken over by algorithms and models for the first time.

More critically, once humanoid robots enter the stage of pure electric drive and software-defined capabilities, their underlying logic becomes highly similar to that of automotive manufacturing: both rely on motors, power semiconductors, control systems, and large-scale software iteration, and both can continuously evolve through data feedback and model training. This causes the 'automobile manufacturing capability' itself to spill over into the capability of 'building embodied intelligent systems.' For leading automakers, humanoid robots are no longer just purchased equipment but a natural extension of the manufacturing system.

From a broader manufacturing perspective, what Atlas represents is not just a single-point efficiency improvement but a shift in the labor paradigm: when skills can be learned by models, synchronized via the cloud, and rapidly replicated, manufacturing is no longer constrained by the number of skilled workers, training cycles, or regional demographic structures. For the global manufacturing industry, this represents both a reshaping of cost curves and a rewriting of the logic of industrial relocation.

In other words, Atlas is not here to 'take away workers' jobs.' Rather, it is compelling the entire automotive and manufacturing industry to re-answer a question: when labor becomes software-based, modular, and replicable, who will still hold the true manufacturing advantage?

© THE END

All materials are sourced from officially published information.

This article does not constitute any investment advice.

This article is originally written by Baker Street Detective and may not be reproduced without permission.

Images are sourced from publicly available materials. Please contact us for removal if there is any infringement.