Pre-sale hits over 1,000 orders in 7 days, humanoid robot priced at 88,000 RMB arrives

![]() 04/27 2025

04/27 2025

![]() 515

515

Author | Mao Xinru

Editor | Bai Xue

When it comes to humanoid robot companies that have garnered significant attention in April, Zhongqing Robotics definitely deserves a mention.

Having completed a Pre-A round of funding of nearly 200 million RMB, dancing the axe dance with "Hyperthyroid Brother", and pre-selling three robot products on e-commerce platforms, Zhongqing Robotics is giving off a bit of a "hero protagonist" vibe.

Recently, Zhongqing Robotics listed three robot products on its e-commerce platform: the humanoid robot PM01 Education Edition priced at 188,000 RMB, the PM01 Commercial Edition priced at 88,000 RMB, and the bipedal robot SA01 priced at 42,000 RMB. The Commercial Edition adopts a reservation-based pre-order model.

This is the second company after Unitree to list robots on e-commerce platforms. It not only directly set a new low price for mass-produced bipedal humanoid robots but also strongly demonstrated Zhongqing Robotics' confidence in mass-producing robots to the outside world.

Since the pre-sale began, PM01 has attracted over 1,000 people to sign up for pre-orders.

In 70 days, it will be deployed in industrial inspections, public service venues, universities, and training institutions, facing the test of market application.

Technology reuse and industrial chain restructuring

are the pricing support for Zhongqing

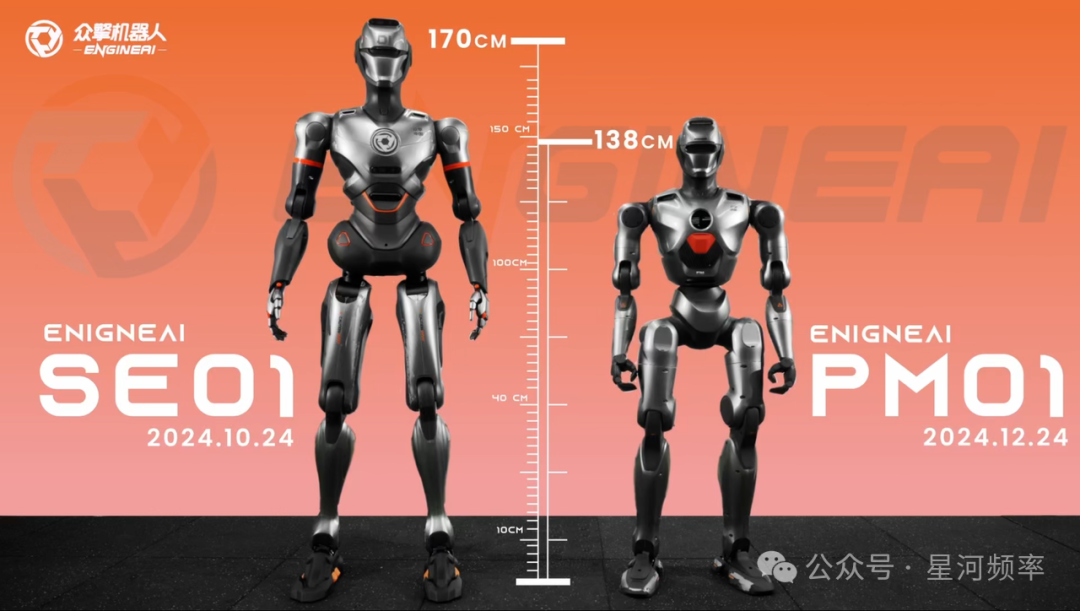

On December 24 last year, Zhongqing Robotics officially unveiled PM01, but the online e-commerce platform did not synchronize its release.

At that time, Zhongqing Robotics "made a big move" and announced that by March 31 this year, the PM01 Commercial Edition and Education Edition would be sold uniformly at 88,000 RMB. During this period, even those who purchased the Commercial Edition could automatically obtain the upgrade rights to the Education Edition.

This move was truly sincere.

Looking back at its repeated "breakouts", Zhongqing Robotics is actually a company that has been established for less than 2 years.

The PM01 officially listed on the e-commerce platform this time stands at 1.38 meters and weighs 40 kilograms. It is a lightweight, high-dynamic, fully open, and versatile humanoid robot positioned for scientific research, education, commercial services, and household scenarios.

With a total of over 23 degrees of freedom throughout the body, the waist motor can rotate freely by 320 degrees, and the movement speed is 2m/s. It has two walking modes: mechanical gait and human-like natural gait. With the help of optical motion capture technology, it accurately collects massive human motion data and adapts to various complex environments through reinforcement learning and imitation learning.

PM01 and Zhongqing Robotics' flagship model SE01 share self-developed joint modules and algorithm frameworks. PM01 focuses on open source directions, and after accumulating algorithm libraries, it feeds back to SE01's industrial scenario adaptation. SE01 focuses on industrial scenarios, driving technological iterations and sinking down to PM01.

Comparing prices, the flagship model SE01 is expected to be priced in the range of 150,000 to 200,000 RMB. Seen this way, the price of Zhongqing Robotics' PM01 is quite attractive.

Such pricing is supported by the team's technology reuse in algorithm frameworks, joint modules, and motion control.

Zhao Tongyang entered the robot industry starting with quadruped robots, successively developing the first-generation robot dog Dogotix, the "Big Dog" DG-160A, and the "Little Dog" DG-48A.

The R&D and mass production experience of the Dogotix first-generation and second-generation bionic quadruped robots by Zhao Tongyang's team provided technical accumulation for their humanoid robot manufacturing. Through experience reorganization, algorithm iteration, and scenario expansion, they achieved technological reuse and leapfrog innovation in algorithm frameworks, joint modules, and motion control.

Inheritance and upgrade of the open-source algorithm framework:

Zhao Tongyang's team initially realized rapid product prototype deployment by reproducing MIT's open-source quadruped robot force control algorithm. In the development of PM01, the team adopted an end-to-end neural network model combined with reinforcement learning to achieve dynamic balance control.

For example, when PM01 completes a front somersault, it needs to adjust its posture within 0.3 seconds. Its algorithm performs 5,000 real-time predictions of the body posture per second. This technological breakthrough directly stems from the accumulation of early quadruped robot motion control algorithms.

Cross-category migration of joint modules:

The Dogotix quadruped robot dog uses a "harmonic reducer + current loop", while PM01 is upgraded to a harmonic force control joint on this basis and integrates a high-precision torque sensor.

For example, by implanting a high-precision shock-absorbing spring in the knee joint, PM01 can output 3 times the torque of a human sprinter within 0.02 seconds. This design directly inherits the engineering optimization experience of Dogotix for harmonic reducers.

Breakthrough in motion control algorithm:

The dynamic balance algorithm verified by the quadruped robot is migrated to PM01, realizing the migration of the robot from a quadruped gait to a humanoid gait.

PM01's "straight-knee gait" draws on the real-time feedback mechanism of the quadruped robot's ground reaction force. By optimizing the center of gravity offset compensation algorithm through reinforcement learning, the center of gravity error during walking is controlled within 0.5 degrees.

In addition, Zhongqing Robotics now has full-stack self-research capabilities ranging from core components to embodied intelligence and motion control algorithms. The core of this price reduction lies in significantly reducing hardware costs through localization substitution and self-developed technology.

PM01 adopts self-developed all-planetary joint modules, domestic harmonic reducers, and low-cost high-precision sensors to replace imported components, which not only ensures high-performance but also reduces procurement costs.

For example, by optimizing the force control algorithm to reduce redundant design, the maximum joint torque reaches 300N·m, and the peak torque density is 203N·m/kg, far exceeding the industry average.

At the same time, Zhongqing Robotics chooses hardware reuse and modular design, reusing the core joint modules of the flagship model SE01 on PM01, reducing R&D costs.

Furthermore, by leveraging the open-source algorithm framework and utilizing reusable code and models from the community, they reduce repeated development costs and shorten the R&D cycle.

Relying on the supply chain resources accumulated in the early stage, PM01's rapid mass production has strong support. For example, PM01's aluminum alloy exoskeleton and self-developed S160 motor rely on the mature manufacturing system in the Pearl River Delta.

Ten-thousand-RMB humanoid robots,

which is better, Unitree or Zhongqing

The first shot in the battle of ten-thousand-RMB humanoid robots came from Hangzhou-based Unitree Technology.

In May last year, Unitree released the humanoid robot Unitree G1 priced at 99,000 RMB, and the product was sold out as soon as it was listed.

This time, Zhongqing Robotics' PM01 has also received great market welcome, indicating that the pricing at the ten-thousand-RMB level is quite attractive.

Currently, there are not many bipedal humanoid robots that have begun mass production and sales. Besides Zhongqing Robotics' PM01 and Unitree's G1, there is also Kinova's Atom priced from 199,000 RMB, UBTECH's Walker S series priced at around 500,000 RMB, and Unitree's H1 priced at 650,000 RMB.

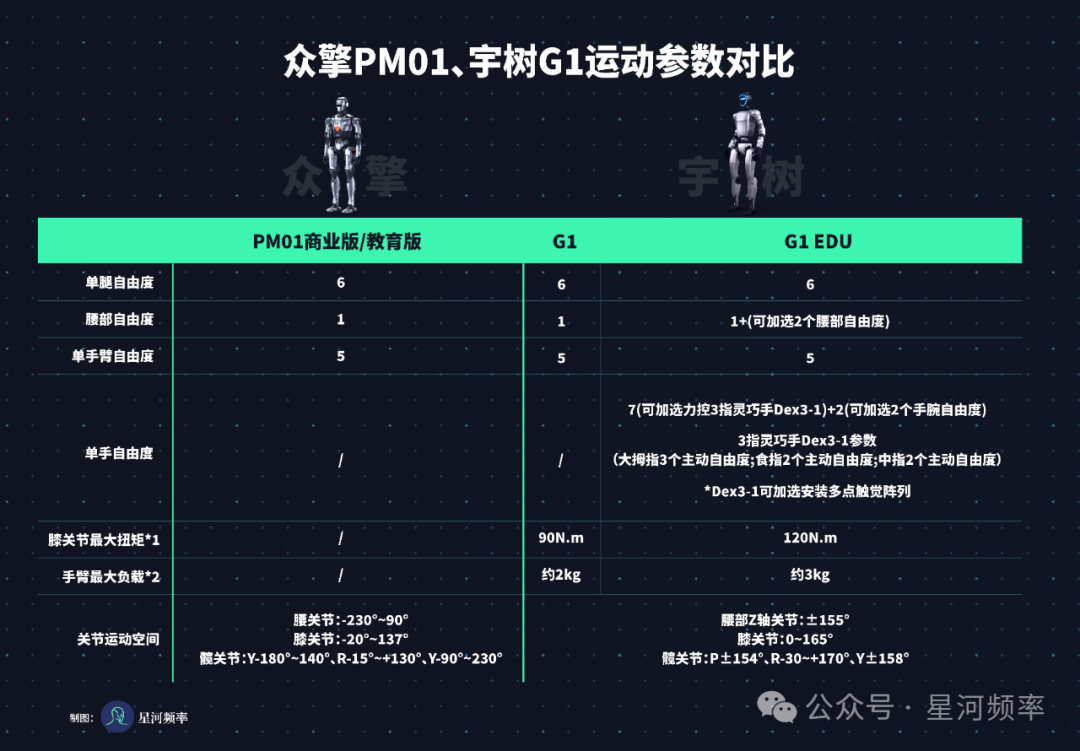

As the only two products with basic models priced below 100,000 RMB, Zhongqing Robotics' PM01 and Unitree's G1 have significant differences worth delving into.

Let's first look at their differences in basic parameters:

Unitree G1 is overall lighter than Zhongqing Robotics' PM01

Unitree offers more flexible configuration options, while Zhongqing Robotics focuses more on balanced basic configurations

The two robots have the same movement speed. Zhongqing Robotics emphasizes anthropomorphic gait, while Unitree emphasizes dynamic balance capabilities

Next, let's look at their core technologies:

First, motion control capabilities:

Zhongqing Robotics PM01: Equipped with a 320-degree rotating waist motor, peak torque of 300N·m (density 203N·m/kg), it has achieved high-difficulty actions such as front somersaults. Through end-to-end neural networks + reinforcement learning algorithms, the accuracy of dynamic gait adjustment reaches ±2cm.

Unitree G1: Uses self-developed low-inertia permanent magnet synchronous motors, with a single joint torque of 120N·m, supporting 23-43 degrees of freedom configurations. It optimizes industrial tasks such as handling and inspections through the UnifoLM large model. Relying on high-precision torque compensation algorithms, it achieves martial arts performances such as carp leaps and 720-degree roundhouse kicks.

Second, perception and interaction systems:

Zhongqing Robotics: Integrates Intel RealSense D435i depth cameras and multi-array microphones, supporting voice interaction and visual SLAM navigation. The interactive core screen enables touch control command response, and developers can extend functions through the open-source SDK.

Unitree: Equipped with depth cameras + 3D LiDAR, supporting 360° environmental perception. Interaction relies on preset action libraries, requiring secondary development to implement complex commands.

Third, hardware architecture:

Zhongqing Robotics: Full harmonic force control joint modules + domestic harmonic reducers, with a core component localization rate ≥ 90%. The hollow joint wiring design reduces the failure rate.

Unitree: Modular design, with joints using self-developed harmonic reducers and sensors adopting RoboSense's 3D LiDAR, but some sensors rely on imports, such as the Intel RealSense D435 depth camera.

From the comparison between Zhongqing Robotics' PM01 and Unitree's G1, it is not difficult to find that both have put a lot of effort into self-developed hardware. At the same time, they both adopt a closed-loop approach in integrating supply chain resources, reducing intermediate markups and effectively controlling production costs.

In terms of performance, Zhongqing Robotics adopts an end-to-end dynamic adaptation algorithm to train anthropomorphic gaits, with a technological path that leans more towards C-end scenario generalization, such as performing axe dances and assisting in patrols.

Unitree is equipped with dexterous finger joints, 3D LiDAR, and the UnifoLM large model to optimize handling paths, showing strong adaptability in industrial scenarios, such as assisting in welding work.

From the perspective of the developer ecosystem, Zhongqing Robotics attracts a developer ecosystem by providing open-source interfaces and resources, using the database to feed back product iterations; Unitree's ecosystem openness is lower, favoring its own technological iterations.

By the way, Unitree, which started mass production and sales first, has now clearly stated on its official website that users should not engage in dangerous modifications or use the robot. It remains to be seen what kind of developments players will create for Zhongqing Robotics, which has a greater degree of openness.

It seems that these two robots, both skilled in martial arts and "dance", have different new choices in training scenarios. In the future, they may also exhibit a stark contrast on the main battlefield of robot services.

In fact, both companies started with robot dogs. Now, Unitree is still making robot dogs, while Zhongqing Robotics has chosen to use robot dogs as a springboard. There are already distinct differences between the two companies in their product iteration paths.

Regardless of the specific differences in products, the mass production of these two ten-thousand-RMB products has provided the industry with practical experience in mass production and commercialization.

At the same time, it can also be seen that after self-developed technology and large-scale mass production, how to achieve a true "consumer-grade experience" for products is a question left for all robot companies.

Mass-producing robots costing ten thousand yuan

The inevitable path for every player

Currently, many humanoid robot companies are striving to achieve mass production plans.

Domestically, companies like Zhiyuan have built their first mass production factory for humanoid robots last year, adopting modular assembly and automated debugging technology, with an annual production capacity of thousands of units. Internationally, Tesla is also actively deploying, with an expected mass production of 5,000 Optimus units by 2025.

On the track of "mass production + commercialization", Unitree and Zhongqing have taken the lead over many companies by directly aiming for ten-thousand-yuan-level products, indicating the continuous improvement of the industrial chain and the maturity of the technology chain.

To truly bring products to the consumer end and achieve sustainable profitability, it is necessary to mass-produce ten-thousand-yuan-level products, adapting to consumer spending habits while providing users with a "consumer-grade experience".

Judging from the current situation, mass-producing ten-thousand-yuan-level products is the future goal but also the current challenge.

The core difficulty in mass-producing ten-thousand-yuan-level humanoid robots still lies in the technical end.

Firstly, hardware costs remain high.

Currently, the cost of core components of humanoid robots accounts for up to 60%-70%, with high-precision joint drive systems such as servo motors, planetary roller screws, and sensors, like six-dimensional torque sensors, being major bottlenecks.

Although many hardware components are accelerating the process of localization, such as the cost of green harmonic reducers dropping from 8,000 yuan in 2019 to 3,500 yuan in 2024, high-precision screws and high-end sensors still rely on imports, making it difficult to compress the overall cost to the ten-thousand-yuan level.

Secondly, the technology is not sufficiently mature. This is particularly evident in motion control algorithms and energy efficiency.

In terms of motion control, there is still much room for improvement in how humanoid robots can truly achieve human-like gait, maintain high stability in walking, turn smoothly, and reduce falls on flat ground.

In terms of energy efficiency, the most intuitive aspect is endurance. It is still difficult for humanoid robots to maintain long-lasting endurance, requiring manual intervention to replace batteries. Compared to some industrial robots that support hot-swapping and autonomous charging to achieve 24-hour operation, the work efficiency of humanoid robots is relatively low.

Humanoid robots also face significant challenges in perception and interaction capabilities. If humanoid robots are to become practical household assistants, adapting to complex and unfamiliar environments and interacting with family members will become tests that robots must face.

Currently, the multimodal sensor fusion of humanoid robots is still in the transition stage from era 2.0 to era 3.0. Era 2.0 only achieved the superposition of vision and touch, while era 3.0 already possesses AI-driven multimodal closed-loop intelligent collaboration capabilities.

However, even with AI models for assistance, when robots face unexpected situations such as items accidentally slipping or children colliding, there are still issues of insufficient response capability.

Thirdly, large-scale production is difficult. Humanoid robots require customized production, with extremely high component compatibility requirements.

Taking Zhiyuan, which has built a mass production factory for humanoid robots, as an example, the Zhiyuan humanoid robot A2 has over 400 components throughout its body. Before the complete machine test, each robot undergoes multiple sub-tests, such as squatting with a single leg load of 30 kilograms, which requires over 2,000 tests. It can be seen that it is difficult for humanoid robots to achieve mass production on a production line.

Currently, the rigid market demand from both the B-end and C-end is continuously forcing robot companies to make breakthroughs in technological iteration and cost reduction. Obviously, Zhongqing has taken a big step forward in these two aspects, taking a step closer to the consumer market at the same time.

At the same time, more and more new energy vehicle companies are actively cooperating with robot companies to provide mature supply chain technology. Robot companies themselves need to focus on AI algorithms and material process innovation, maximizing the integration and utilization of favorable resources to achieve a leap in technology and products.

Companies like Zhongqing and Unitree, which have made significant strides in research and development, mass production, and commercialization, will not be isolated cases in the future.

Only by passing through this "dark forest period" will the "iPhone moment" for humanoid robots arrive.