The Chinese high-speed railway, which has been admired by three US presidents, is changing overseas users' travel experience

![]() 08/20 2024

08/20 2024

![]() 632

632

Editor | Jiran

Three US presidents have expressed their admiration for China's high-speed railway in their own names.

On August 13 last week, Tesla CEO Elon Musk and former US President Donald Trump had a live dialogue broadcast. In the broadcast, Trump praised China's high-speed railway: "unbelievable", "without any flaws", "there's nothing similar in the US", and netizens called Trump's admiration "in his own name". It's not just Trump; Barack Obama and Joe Biden have also expressed their admiration for China's high-speed railway in their own names. In his second State of the Union address, Obama pointed out that the US should take China's high-speed railway as an example and enable 80% of the US population to enjoy high-speed railway in the next 25 years.

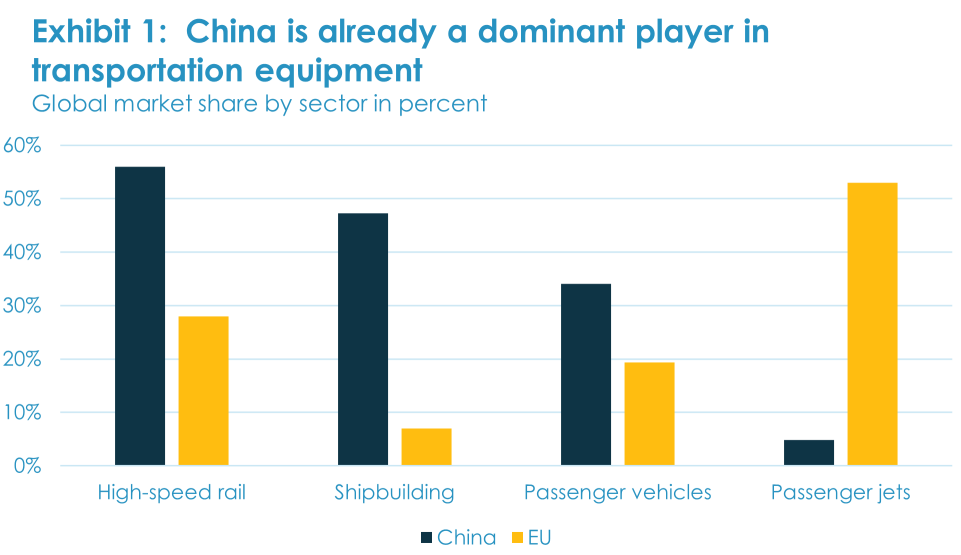

Biden told his fellow villagers in his hometown of Pennsylvania, "Do you know how fast the high-speed railway China is building goes? 300 miles per hour (about 483 kilometers per hour)!" Behind Trump, Obama, and Biden's admiration for China's high-speed railway lies another side of China's high-speed railway beyond our daily lives: it is leading the global development of high-speed railway and changing the travel experience of overseas users. MERICS data shows that in 2022, CRRC occupied 56% of the global market share, followed by Alstom with a 15% market share, a significant gap from CRRC.

Image source: MERICS

The gap between China and the US in high-speed railway is widening significantly. According to Xinhua News, by the end of 2023, China's railway operating mileage reached 159,000 kilometers, including 45,000 kilometers of high-speed railway, covering almost all large and medium-sized cities in China, and even many county-level cities have opened high-speed railway stations in recent years.

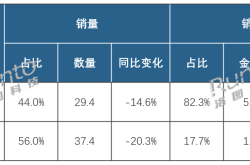

Even the "Roof of the World," the Qinghai-Tibet Plateau, has been connected by high-speed railway. The existence of permafrost, harsh snowy weather, high altitude hypoxia, and many other issues poses significant challenges to the construction of the Qinghai-Tibet Railway, from construction to EMU design to high-speed railway operation. However, China's high-speed railway has not only overcome these challenges but also set many world records. The 525-meter-long Zangmu Railway Bridge on the Lhasa-Linzhi Line is the largest and highest arch bridge in the world. The highest part of the railway line is over 5,100 meters above sea level, setting the highest altitude for any electrified railway in the world. According to Railway Technology, a global railway professional media, the Qinghai-Tibet Railway ranks first among the top 10 railways with the highest altitude in the world.

Image source: Railway Technology

In contrast, the US still does not have a national high-speed railway network. The 1,287-kilometer California High-Speed Rail project, proposed in 2000 as the first high-speed railway project in the US, was approved in August 2005, but it took CHSRA (California High-Speed Rail Authority) 10 years to break ground in Fresno. The first 273.6 kilometers of the Central Valley segment is expected to be operational in 2028, and a direct connection between San Francisco and Los Angeles in less than three hours is expected by 2033. This means that it may take nearly three decades for the US to complete a high-speed railway project of over 1,000 kilometers.

Image source: CHSRA

From technological laggard to global leader, China's high-speed railway has staged a real-life "underdog" comeback story.

Railways used to be a pain point for Chinese travelers

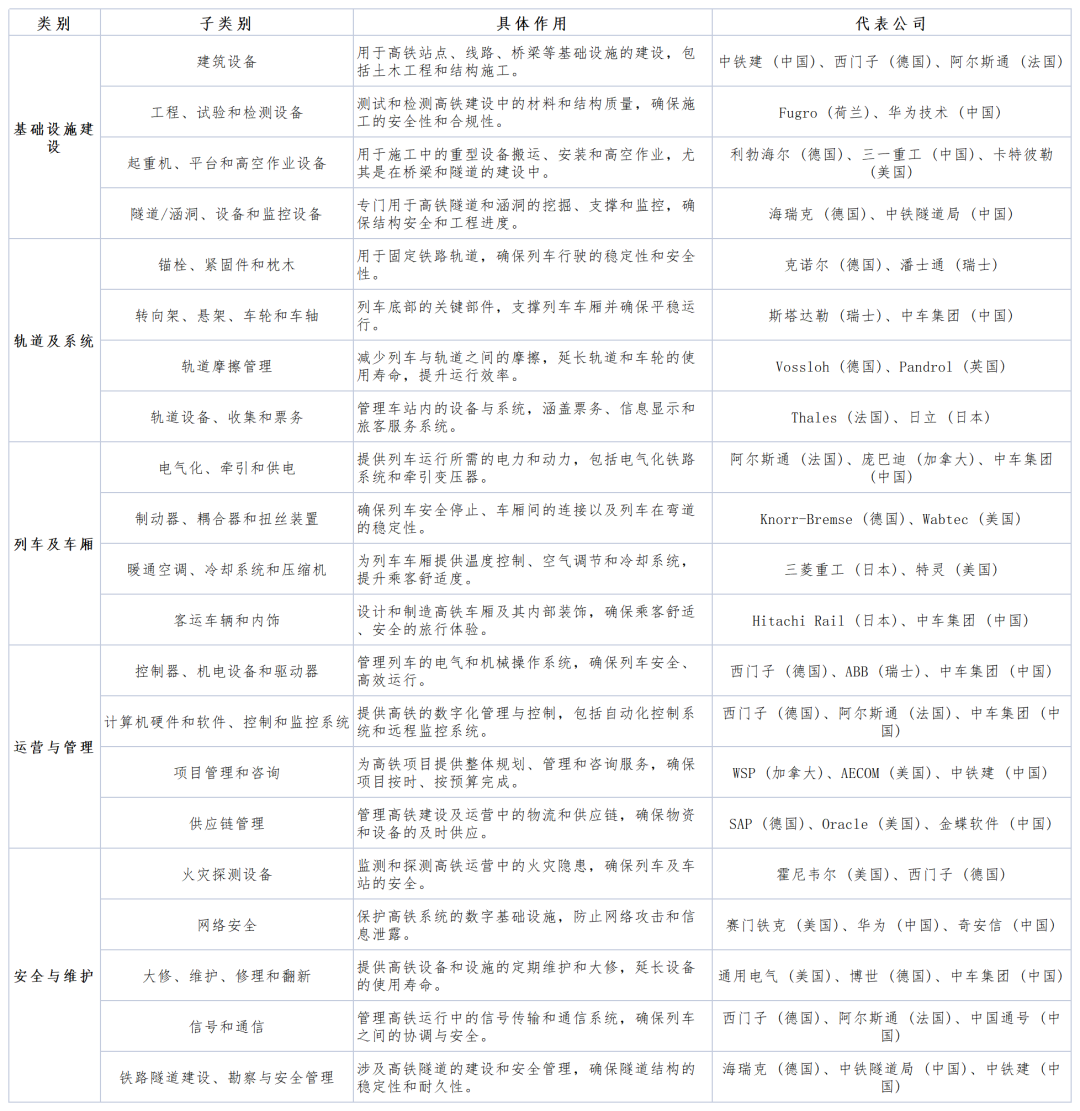

During the 2008 Spring Festival, a rare large-scale low-temperature, rain, snow, and freezing disaster swept across China, putting enormous pressure on the transportation network. The Beijing-Guangzhou Railway, one of the most important railway trunk lines in China, connects many important cities in the north and south of the country. Continuous large-scale snowfall and low temperatures led to power outages and train disruptions on some sections. This was a common problem faced by ordinary trains in disaster weather conditions in the past. Was there a way to solve it? High-speed railway was thus highly anticipated. Compared to other industries, the high-speed railway industry chain is extremely complex. Although the broad categories of high-speed railway include high-speed railway infrastructure construction, tracks and systems, trains and carriages, operation and management, safety and maintenance, each category contains numerous subcategories. For example, tracks and systems involve anchor bolts, fasteners, and sleepers; bogies, suspensions, wheels, and axles; track friction management; track equipment, collection, and ticketing. Daily operation and management involve controllers, electromechanical equipment, and drives; computer hardware and software; control and monitoring systems; project management and consulting; supply chain management, etc.

Image source: Based on Railway Technology's public information

Taking high-speed railway infrastructure construction as an example, on the one hand, compared to flat terrain, construction in plateaus, mountains, and straits is more challenging. For example, for high-speed railway tunnels that need to cross mountains, the common technique is drilling and blasting, which involves precise control of explosives or the use of techniques such as pneumatic blasting fireworks to break through hard rock strata. However, this technique requires advanced machinery and equipment.

Image source: Railway Technology

At that time, specialized blasting equipment and technology were controlled by overseas enterprises such as Atlas Copco (now Epiroc), Herrenknecht AG, Orica, Sandvik, and Normet. Orica is one of the world's largest blasting service providers, offering efficient and safe blasting technology, which is used in precise blasting for high-speed railway tunnels. Herrenknecht is a world-leading tunnel boring machine manufacturer, and its equipment is widely used in global tunnel and underground engineering projects. Chinese enterprises had to rely on imports.

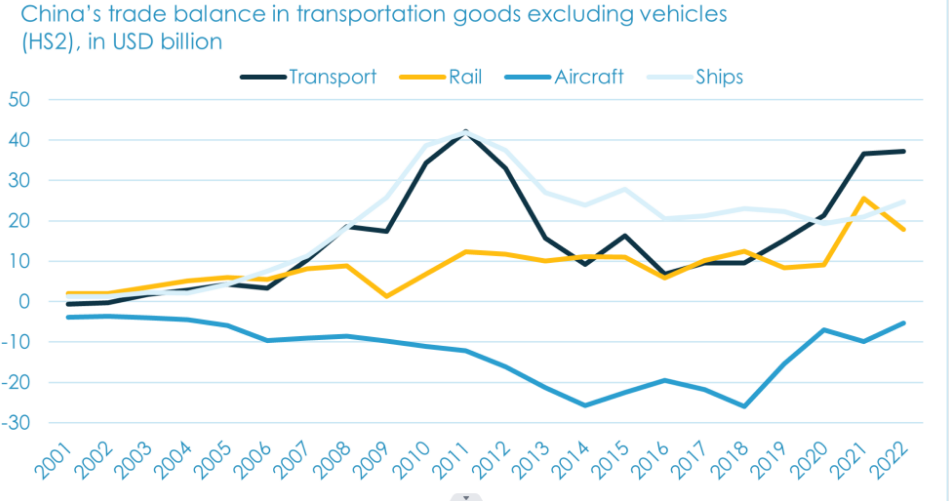

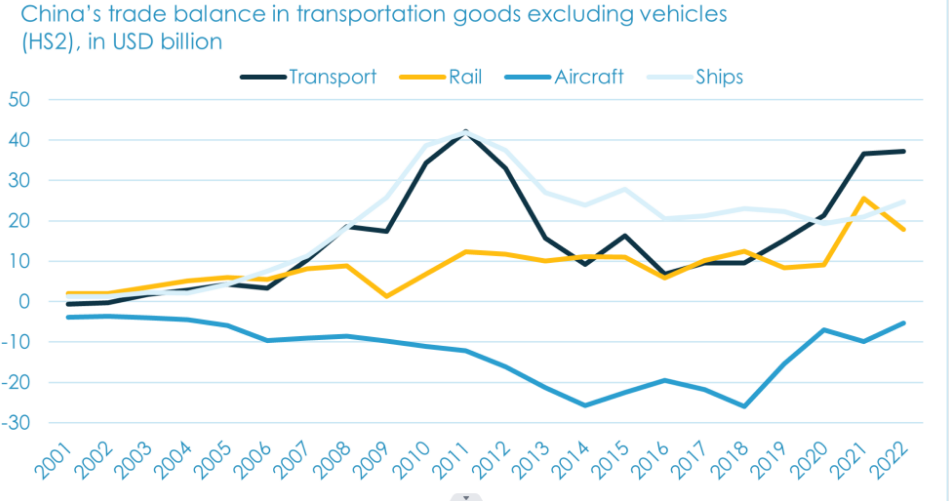

The same situation exists with high-speed railway steel. Due to its ability to withstand high weights and pressures, steel is widely used in important components such as railway gantries, platforms, and overhead signaling systems, as well as in complex nuts and bolts used to connect and secure railway tracks. However, steel is prone to corrosion, especially in acidic weather conditions. While painting steel tracks is cost-effective, it typically has a relatively short lifespan of only 10 years. Long-term maintenance of rusted tracks adds significant costs. The solution to this problem is hot-dip galvanizing technology and aluminum coating technology. Taking hot-dip galvanizing as an example, it is a unique process where components are uniformly and completely coated with molten zinc, ensuring a permanent surface treatment with maximum damage resistance. Without the need for maintenance and downtime, the lifespan can typically reach 70 years. However, these technologies have long been dominated by overseas enterprises such as Nippon Steel, JFE Steel, ArcelorMittal, ThyssenKrupp, and AK Steel. These enterprises have dominated the global steel coating market through patent protection and long-term technological investments. Not only in high-speed railway infrastructure, but many sub-sectors were also previously dominated by foreign enterprises. In the areas of computer hardware and software, control and monitoring systems, the control and monitoring technology of high-speed railway systems, including automatic train control systems and train dispatching systems, is dominated by European enterprises such as Siemens and Alstom. The signaling system of high-speed trains is dominated by Europe's ETCS (European Train Control System) and the US's PTC (Positive Train Control); the braking system and coupler technology of high-speed trains are dominated by enterprises such as Germany's Knorr-Bremse and Switzerland's Stadler; high-end track fastener technologies such as elastic sleepers and seamless rail welding technology are also dominated by overseas enterprises; and key equipment such as air conditioning and cooling systems inside trains were previously provided by European enterprises such as Siemens and Alstom. Reflecting on import and export data, although China's railway industry trade surplus continued to grow before 2010, the overall growth was relatively slow, and the trade surplus was relatively small, indicating that China's railway equipment and technology were less competitive in the international market, with limited export capabilities and a significant need for imports of high-end core technologies and equipment.

Image source: MERICSAccording to MERICS data, in 2006, CRRC had only 88 registered technology patents.

China's high-speed railway comeback: a historic opportunity

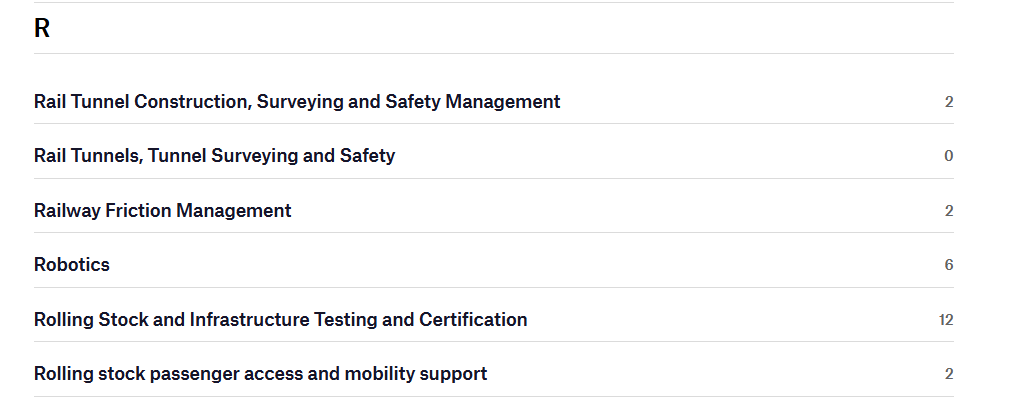

The turning point came around 2008. In fact, as early as 2004, China's Ministry of Railways (later renamed China Railway Corporation) threw a blockbuster plan to the world: to build a four-vertical and four-horizontal high-speed railway network with a total mileage of 12,000 kilometers, with an even larger market size in the future; at the same time, it would first procure 140 EMUs. This was a bold move that no other country in the world dared to imagine at that time. It was also a historic big order for global high-speed railway giants. The "money-swallowing" ability of high-speed railways can be seen from some future investments. In 2008, the domestic government stimulated railway demand through large-scale investment, and railway infrastructure investment increased three-fold to 749 billion yuan in 2010. The strong demand brought about by policy stimulus, on the one hand, strengthened international partnerships. To enter the Chinese market, Alstom, Bombardier, Siemens, and Kawasaki Heavy Industries all transferred technology to their Chinese partners by establishing joint ventures. This not only filled China's technological gaps but also laid the foundation for China's technological leadership. The reason why foreign enterprises were willing to transfer technology lies in the fact that the high-speed railway industry is a capital-intensive niche industry. On the Railway Technology website, there are only two enterprises involved in the design, survey, and safety management of railway tunnel construction, railway friction management, rolling stock and passenger access, and mobility support.

Image source: Railway Technology

At that time, China was the only available sales market for overseas enterprises.

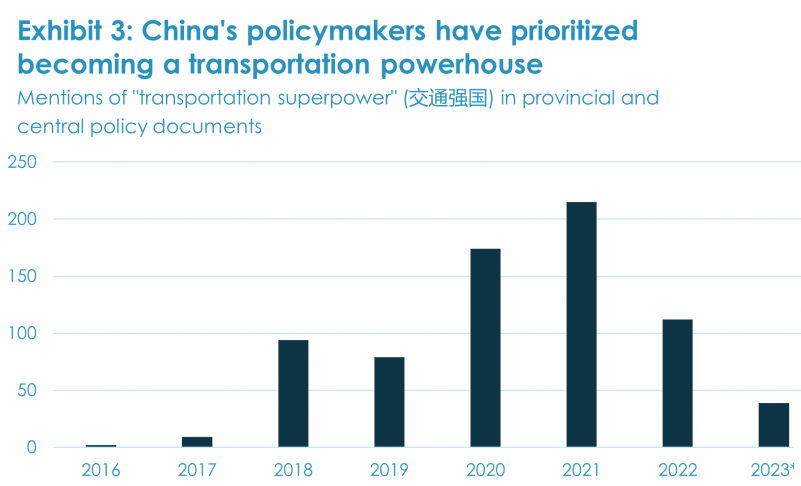

On the other hand, high demand was also stimulating Chinese enterprises to actively innovate. The domestically produced CRH380, introduced in 2010, still relied on foreign patents and standards, but it used Chinese design. The introduction of CR400A in 2017 significantly reduced China's reliance on foreign technology for high-speed railways, laying the foundation for China's high-speed railway to go global. In 2013, the Chinese government proposed the "Made in China 2025" strategy, with advanced railway equipment, high-tech ships, and aviation equipment all featured in the 2025 strategy and supporting policy documents. Since 2016, the strategy of building a powerful transportation country has frequently appeared in relevant high-level documents.

Image source: MERICS

The core of the transportation power strategy is to achieve comprehensive control over the strategic value chain, rather than simply moving upwards, thereby enhancing the global status of Chinese multinational corporations. For example, in the field of high-speed railways, the goal is to achieve significant breakthroughs in 30,000-ton heavy-haul trains and 250 km/h high-speed wheeled freight trains.

Driven by policies, the domestic high-speed railway industry has ushered in rapid development. Firstly, local innovation and independent innovation have been strengthened. For example, the Ministry of Railways coordinated with CSR and CNR (later merged) to promote local innovation. Universities, research institutions, national laboratories, and enterprises have established a research-production cooperation mechanism to accelerate China's independent innovation in high-speed railways. With the enhancement of domestic local innovation and independent innovation capabilities, China's high-speed railway has become less dependent on foreign technology. Reflecting on import and export data, China's railway import and export trade surplus has risen steadily since 2011, exceeding $20 billion for the first time in 2021. As mentioned above, CRRC's related technology patents have soared to 1,800 in 2019. In July 2023, CRRC's CR450, the next-generation high-speed railway with a speed exceeding 450 km/h, made its debut and is breaking through technological boundaries through the testing of ultra-high-speed maglev trains (up to 1,000 km/h).

Image source: MERICS

Secondly, a large number of universities have provided a large number of high-speed railway-related talents for enterprises, resolving the contradiction between the surge in high-speed railway projects and the shortage of talents. The development of high-speed railways cannot be separated from sufficient railway talents. A decade ago, railway majors were one of the most popular majors among young Chinese students. Looking abroad, taking the UK as an example, the shortage of high-speed railway talents is currently a significant obstacle to the development of high-speed railways in the UK. Dan Hughes, the Infrastructure Director of GetLink, which operates the cross-Channel Tunnel linking the UK and France, said that the small number of young people studying engineering courses at university has led to a decrease in skilled engineers and even engineering companies, posing significant challenges for corporate recruitment.

Third, it benefits from the vertical integration of the domestic high-speed rail industry chain. This includes the gradual development of the domestic mobile internet, which has driven the maturity of internet ticketing; the development of cloud computing has enabled the organic integration of electricity, networks, and clouds; the mobile internet has driven the continuous upgrading of the 12306 booking system, gradually eliminating ticket scalpers from the market; and AI technology has been applied on a large scale to fields such as face recognition and security checks. All of these have provided China's high-speed rail with powerful and replicable practical experiences for its overseas expansion.

High-speed rail going global: full industry chain, full project, and diversification

On September 7, 2023, the Jakarta-Bandung high-speed rail (Jakarta-Bandung HSR) jointly constructed by China and Indonesia was officially opened to traffic. According to China News Weekly, this high-speed rail project is "the first time that China's high-speed rail has been constructed overseas with a full system, full elements, and a complete industry chain, using Chinese technology and standards throughout the entire line." The Jakarta-Bandung HSR project, which took eight years to build, won the bid in 2015 and started construction in 2016. It is not only China's first overseas high-speed rail project but also the first high-speed rail line in Southeast Asia. The entire Jakarta-Bandung HSR project is managed by PT KCIC, a joint venture between China Railway and Indonesian state-owned enterprises. Chinese enterprises participate in the entire system, all elements, and the entire industry chain, making it a representative project of China's high-speed rail going global.

The Jakarta-Bandung HSR train has been named Whoosh, an acronym for Waktu Hemat (saving time), Operasi Optimal (optimal operation), and Sistem Handal (reliable system). The naming itself reflects the affection of the Indonesian government and people for this high-speed rail, and many Indonesians have indeed expressed high praise for Whoosh.

A user on Whats New Indonesia commented that the Whoosh train is not only clean but also provides comprehensive facilities. For example, the middle carriages offer a mini-cafe equipped with coffee machines and various food and beverage facilities, and the toilets have special facilities for people with disabilities.

Image source: Whats New Indonesia

According to Antara News, as of January 27, 2024, 1.4 million people have traveled between Jakarta and Bandung using the Whoosh high-speed train, with occupancy rates ranging from 60% to 80%. From February 3 this year, Whoosh will adopt a dynamic pricing mechanism to achieve its goal of serving 33.672 million passengers in 2024.

Image source: Whats New Indonesia

Additionally, the Moscow-Kazan high-speed rail project in Russia is managed by RCHSR, a joint venture established by Russian Railways and China Railway. It is built through a joint venture approach.

Supported by the Belt and Road Initiative, China's high-speed rail has successively won numerous global high-speed rail projects, expanding its presence across Asia, Europe, Africa, the Middle East, and South America.

Image source: Compiled based on public information from Railway Technology

Apart from participating in the construction of high-speed rail lines, CRRC is also continuously expanding its presence. In June this year, the first 18 carriages of CRRC's 2050 series double-decker train were put into service on Montreal's urban rail network in Canada. CRRC has also designed the third-generation electric train service locomotives and vehicles for the Malaysian market, which will be put into service on the 950-kilometer-long Gemas-Johor Bahru electric double-track line.

Moreover, for some overseas high-speed rail lines, China's high-speed rail not only participates in the construction of the project but also provides locomotives. For example, in the modernization project of the Ethiopia-Djibouti Railway, the Belgrade Center-Stara Pazova section was jointly undertaken by China Railway International and China Communications Construction Company, and some of the trains were provided by CRRC. In other words, China's high-speed rail going global represents a full industry chain, full project, and diversified approach.

The "high-speed rail going global" model is being replicated in more fields

Looking ahead, the global influence of China's high-speed rail will continue to expand. On the one hand, while vigorously developing tourism, the Middle East is actively improving its high-speed rail infrastructure. In May this year, Elena Sorlini, CEO of Abu Dhabi Airports Company, stated that the new terminal at Abu Dhabi International Airport could be connected to the UAE's growing rail network, and plans are underway to make this happen. On the other hand, driven by the practical pressures of reducing carbon emissions and improving domestic transportation networks, many countries are actively promoting the development of the high-speed rail industry.

This year, the Asian Development Bank has provided special funds for the Philippines' high-speed rail project; Ireland has called for a faster and broader rail network; the EU's "Connecting Europe" Fund has announced a 7 billion euro grant for transport subsidies; the Port of Vancouver has approved a flyover project to improve rail capacity; Serbia plans to build a 150 million euro railway line in Nis, among other initiatives. With its leading technological advantages and project experience, China's high-speed rail may secure more orders in the future. However, the globalization of China's high-speed rail also faces short-term challenges, including the continued import dependence in key components. For example, highly durable bearing steel still requires the import of screws from Japan. Strengthening comprehensive management of high-speed rail projects may be a crucial issue for China's high-speed rail going global in the future. Taking the Jakarta-Bandung HSR project in Indonesia mentioned above as an example, the project's actual implementation was not without challenges. According to Thedi Plomat, the project was initially not included in Indonesia's national railway master plan, and no construction permit was issued to the contractor and developer, leading to a forced stoppage of the project.

Although the relevant Indonesian authorities subsequently issued the necessary permits, the rapid pace of the project resulted in several negative impacts. For instance, the environmental impact assessment, which normally takes 12 to 18 months to complete, was conducted in just seven days. An independent Indonesian analyst noted that the assessment overlooked crucial components, including the project's impact on landslides, geological fault lines, and watersheds. However, this is just an episode in China's high-speed rail projects going global. In the future, China's high-speed rail will continue to expand overseas, bringing the "Chinese travel experience" to international users. A similar growth story is unfolding in China's shipbuilding industry. Relevant data shows that China accounted for 47.3% of global production in 2022.

Six of the world's top ten shipyards are Chinese enterprises, making China the world's largest shipbuilding nation. The successful test flight of the C919 suggests that the stories of China's high-speed rail and shipbuilding will also unfold in the aerospace industry in the future. While facing short-term challenges such as Airbus and Boeing's technological monopoly and geopolitical conflicts affecting exports, China will gradually overcome these challenges under the guidance of the national strategy for becoming a transportation powerhouse, thereby promoting the overseas expansion of China's high-end manufacturing products.