How Hengtong Optic-Electric's 29.5 Billion Yuan Submarine Cable Order Will Illuminate Its 60 Billion Yuan Empire

![]() 08/14 2025

08/14 2025

![]() 644

644

When the World Economic Forum bestowed the 11th batch of "Lighthouse Factory" plaques upon Hengtong Optic-Electric, it marked a pivotal moment in reshaping the global optical communication industry's narrative.

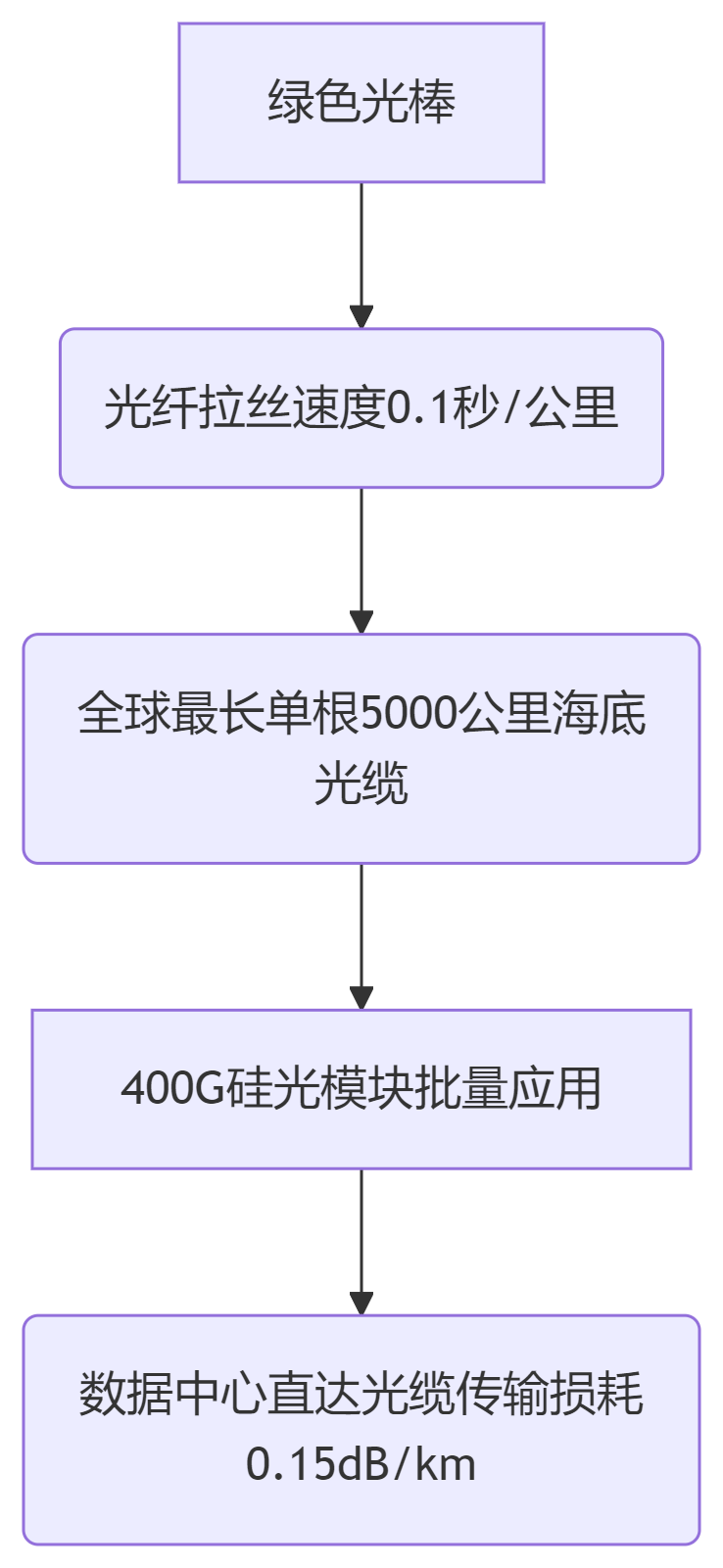

This intelligent factory, nestled in Wujiang, Suzhou, boasts a fiber drawing speed of 0.1 seconds, a pass rate of 98%, and a comprehensive digital twin system. It heralds that Chinese manufacturing has ascended to the zenith of Industry 4.0.

Under the glow of this lighthouse, Hengtong Optic-Electric's journey transcends optical communication itself. A 29.5 billion yuan submarine cable order is poised for execution, high-voltage wire harnesses have found their way into Xiaomi vehicles, and UHV wires traverse the Tianshan Mountains. A grandiose tale of connectivity and empowerment across all walks of life is slowly unfolding.

Digital Nirvana Across the Entire Optical Communication Chain

Hengtong Optic-Electric's lighthouse factory certification is the culmination of 30 years of technological accumulation.

Four Quantum Leaps in the Digital Revolution:

1. Green Manufacturing: Reduced energy consumption by 46% and carbon emissions by 38% in optical fiber preform production.

2. Intelligent Quality Control: AI visual inspection replaced 300 manual processes.

3. Flexible Production: Compressed order response cycle from 72 hours to 8 hours.

4. Supply Chain Empowerment: Driven over 300 suppliers in the industry chain to adopt cloud technology.

Chairman Cui Genliang proclaimed at the unveiling ceremony, "This lighthouse belongs not only to Hengtong but serves as a beacon for China's high-end manufacturing." Behind this achievement stands robust support from over 8 billion yuan in R&D investment over five years, equivalent to injecting 7% of annual revenue into the innovation engine.

The Deep Blue Colossus Behind the 29.5 Billion Yuan Order

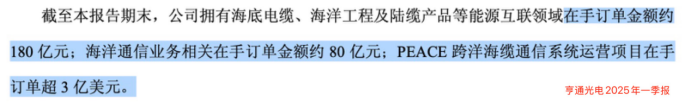

As 40% of global submarine cables enter their retirement cycle, Hengtong Optic-Electric's marine business is poised to seize an epochal opportunity.

Marine Business Layout in 2025

Triple Strategic Depth:

Wind Power Frenzy: Secured the bid for the Moray West offshore wind power project in the UK (worth 2.3 billion yuan). Mastering 500kV cross-linked polyethylene insulated deep-sea cable technology, the projected global installation of 2,000GW of offshore wind power by 2050 heralds a trillion-yuan market.

Communication Upgrades: Replacing 400,000 kilometers of submarine cables laid before 2000, enhancing computing power, and landing the Meta transatlantic 6-fiber pair system order. Energy Revolution: Flexible DC technology addresses offshore wind power fluctuations, and the Zhoushan Archipelago microgrid project achieves 100% new energy supply.

After adding 1.5 billion yuan in orders in July, the backlog approached 30 billion yuan, sufficient to support a 25% revenue growth over the next three years.

Coordinated Offensive of Three Aces:

As the submarine cable business surges ahead, Hengtong Optic-Electric's terrestrial layout is equally formidable.

1. Smart Grid: The "aorta" of UHV construction. The 1100kV UHV wire passed the extreme cold test on the Qinghai-Tibet Plateau. The State Grid's 380 billion yuan investment sparked a surge in wire demand. Grid revenue will exceed 21 billion yuan in 2024 (accounting for 35%).

2. New Energy Vehicles: A game-changer in high-voltage wire harnesses. In the 37.5 billion yuan market in 2025, Hengtong's share is projected to rise from 8% to 15%.

3. Copper Conductors: An underestimated cash cow. High-precision copper foil is utilized in server PCB backplanes, and liquid-cooled copper pipes boast a thermal conductivity of 401W/m·K, accounting for 18% of revenue but contributing 25% of gross profit.

These three major businesses form a synergistic "land-sea collaboration" with submarine cables. Submarine cable laying ships require UHV power supply, automotive wire harnesses reuse optical cable shielding technology, and copper conductors support data center liquid cooling systems.

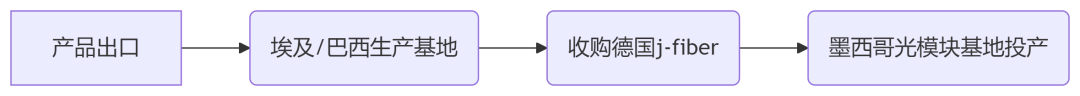

Strategy of Establishing 12 Overseas Bases

Faced with trade barriers, Hengtong Optic-Electric's internationalization strategy is exemplary.

Three-Step Leap in Localization Strategy

Regional Operation Results:

In 2024, the proportion of overseas revenue will rise to 32%. With the Mexican factory ramping up production, the export cost of optical modules will decrease by 18%. Chang Jianming's assertion at the overseas annual meeting was emphatic: "Globalization is not a choice but a necessity for survival."

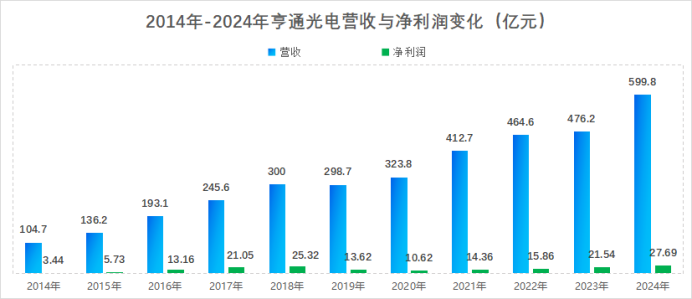

Efficiency Halo Under 60 Billion Revenue

The aura of the lighthouse factory must ultimately translate into a leap in financial metrics.

Trio of Lean Management:

1. Inventory Optimization: The intelligent forecasting system reduced inventory turnover from 68 days to 52 days.

2. Cost Control: Digital twins lowered trial production costs by 47%.

3. Gross Margin Restoration: The proportion of high-end products increased to 45% (from 28% in 2019).

Although the net profit rate in 2024 stood at 4.8%, the quality of growth improved markedly. Net operating cash flow reached 3.86 billion yuan (2.1 times the net profit). The gross margin of the submarine cable business climbed to 35% (driving the overall gross margin up by 3.2%). The R&D capitalization rate is kept at 18% (below the industry average).

The robust start of Q1 revenue in 2025 at 13.27 billion yuan (+12.6%) indicates that the lighthouse effect is beginning to unfold.

From an Optical Fiber Giant to the Neural Hub Connecting the Universe

Aboard Hengtong's marine engineering ship, a 9,000-ton ±525kV flexible DC submarine cable sinks into the Atlantic trench.

This energy artery, transporting power from the UK wind farm, intertwines with UHV wires on the Qinghai-Tibet Plateau, high-voltage wire harnesses in Xiaomi cars, and optical modules from the Mexican factory, forming a colossal network spanning land, sea, and air. It embodies not just Hengtong Optic-Electric's industrial layout but also a dual channel of energy and information that fuels digital civilization.

From the full-chain layout of optical communication to the pinnacle of marine engineering, from UHV wires to automotive high-voltage nerves, Hengtong Optic-Electric's diverse breakthroughs affirm the ultimate laws of high-end manufacturing. Within the moat constructed by basic materials and core equipment, technology reuse and scenario innovation will unleash exponential energy.

When Cui Genliang declared that "every inch of land on earth should be connected," Hengtong Optic-Electric's ambition transcended mere business. It aspires to become an infrastructure builder enabling humanity to expand its living territory.

As the 29.5 billion yuan order gradually materializes and the lighthouse factory experience is replicated across 12 overseas bases, Hengtong Optic-Electric's journey towards the 100 billion yuan mark has sounded the clarion call. In this grand narrative of 2,000GW offshore wind power and a 22.3 billion dollar optical module market, the brilliance of this Chinese lighthouse is destined to illuminate an even broader deep blue expanse.

Note: (Disclaimer: The article content and data are for reference only and do not constitute investment advice. Investors should act accordingly at their own risk.)