South Korea's chip industry rakes in hundreds of billions of dollars, Samsung workers strike, prices soar affecting Chinese manufacturing?

![]() 07/16 2024

07/16 2024

![]() 543

543

South Korean media reports indicate that the country's exports of ICT products surged 28% year-on-year in the first half of this year, reaching $108.8 billion, setting a second-highest record in history. One of the export destinations for South Korean chips is China, and the significant price hikes in South Korean chips have undoubtedly cost Chinese manufacturing dearly.

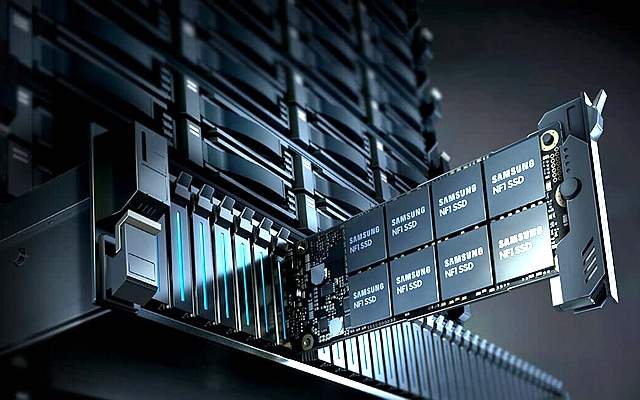

Among the high-tech products exported by South Korea, memory chips, where South Korea has a competitive edge, naturally account for the highest proportion. Samsung and SK Hynix, the top two memory chip companies globally, collectively hold nearly 70% of the global market share in memory chips.

In recent decades, South Korea has also actively developed emerging chips such as automotive chips. The automotive chip market is even broader, with smartphones requiring around 100 components, while fuel-powered vehicles need over 300 automotive chips, and new energy vehicles can require up to a thousand chips. This vast market potential has prompted the South Korean chip industry to actively engage in the automotive chip sector.

South Korea indeed possesses the strength to develop many advanced chips. In memory chips, South Korean companies were the first to mass-produce the world's most advanced 300-layer NAND flash. In chip manufacturing, Samsung has mass-produced 3-nanometer technology, tying with TSMC as the global leader. Advanced technologies are now in high demand for mobile phone chips, AI chips, etc., as they can enhance performance and reduce power consumption.

At this juncture, Samsung Semiconductor, which boasts the most advanced technology and holds the largest market share in memory chips, has reported news of worker strikes. This is bound to further drive up chip prices, enabling South Korean chips to earn more revenue, while Chinese manufacturing, which requires a large number of chips, may have to pay a higher price.

As the world's largest manufacturing nation, China's mobile phone, AI, and other industries require a significant amount of memory chips. China imports memory chips worth up to $100 billion annually. In such a scenario, a 40% increase in memory chip prices would cost China an additional $40 billion, or nearly 300 billion yuan.

China's new energy vehicle industry has become the strongest globally, producing nearly 70% of the world's new energy vehicles and selling nearly 60% of them. New energy vehicles require numerous memory chips and automotive chips, many of which come from South Korea. Therefore, the new energy vehicle industry will also bear the cost of rising chip prices.

Chip price increases are not solely driven by supply and demand. In the past, South Korean chip companies were fined hundreds of millions of dollars by the United States for manipulating chip prices. During chip price hike cycles, South Korean chips have repeatedly used excuses like floods and fires to push up prices. Now, the worker strikes at Samsung Semiconductor will undoubtedly add fuel to the fire of rising chip prices, accelerating their increase.

In fact, a few years ago, Chinese chips did challenge South Korean chips. At that time, two Chinese memory chip companies successfully mass-produced memory chips and even took the lead in mass-producing 232-layer NAND flash memory chips in 2022. However, subsequent US restrictions led to a standstill in China's memory chip technology, and Chinese memory chips only account for about 4% of the market share. With technological advantages regained, American and South Korean memory chip companies, which hold over 90% of the market share, have jointly raised prices again.

Market research firm TrendForce estimates that global memory chip prices have risen 40% since the second half of last year, boosting Samsung's profits by nearly tenfold and significantly increasing the profits of SK Hynix and Micron, among others. Recently, TSMC announced that it had reached an agreement with US chip companies. Due to rising costs of advanced technologies like 3-nanometer, chip foundry prices will further increase, which will further push up prices of other chips.

Chip prices in the US and South Korea are likely to accelerate, targeting Chinese manufacturing, which purchases nearly 70% of the world's chips annually. Advanced chips are currently controlled by the US, while Samsung and TSMC are responsible for manufacturing the most advanced chips. With advanced technologies, they can freely raise prices, leaving Chinese manufacturing to bear the burden.

Nevertheless, in recent years, China has also been vigorously developing its chip industry. China has chosen to prioritize the development of mature process chips, which still have significant demand. It is estimated that mature process chips account for 70% of the chips needed by Chinese manufacturing. By developing mature chips to accumulate technology and gradually progressing to advanced chips, China has already seen results. It is widely believed that China now has the capability to develop 7-nanometer technology, and it is expected that China will no longer be constrained by overseas forces in advanced chips in the future.