"Old Guns" No Longer Reap Easy Profits

![]() 08/14 2025

08/14 2025

![]() 610

610

Introduction

The crux is no longer who earns less but the collapse of the established order.

Competition in the automotive market is intensifying, making it increasingly challenging for automakers to turn a profit.

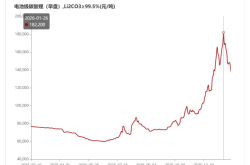

Last year, the combined net profit of 18 major domestic listed automakers amounted to less than 80 billion yuan, equivalent to just one-third of Toyota's earnings, prompting widespread industry reflection on the imbalance between scale and efficiency in China's automotive industry. However, an examination of the first-half financial reports of traditional multinational automakers reveals that the decline in profitability is far from limited to Chinese automakers.

The performance of several mainstream multinational automakers in the first half of 2025 shows that, despite relatively stable operating revenues for most, net profits suffered a collective "avalanche," with across-the-board declines exceeding double digits.

General Motors' net profit fell by 20.9%; Porsche, Stellantis, Ford, Renault, and others were not spared, with their net profits halved; Audi's revenue increased slightly, but its profit plunged by nearly 40%; Mazda swung from a profit of 49.8 billion yen to a loss of 42.1 billion yen.

The collective collapse in profitability among traditional giants is thunderous. In our perception, multinational giants have always leveraged brand prestige and technological barriers to enjoy substantial premiums and high profits. However, the dramatically transformed automotive market is violently eroding the profits of these established players, quietly bringing an end to the era of effortless earnings.

01 The Dilemma of Multinational Giants

By brand, the declines vary.

General Motors' revenue increased slightly by 0.8%, while its net profit fell by 20.9%; Porsche's revenue declined, and its net profit plummeted by 66.6%, leaving only 718 million euros; Audi's revenue remained growth, but its profit fell by nearly 40% to 1.346 billion euros; Mazda's operating performance in the second quarter fell across the board, with net profit swinging from a profit of 49.8 billion yen in the same period last year to a loss of 42.1 billion yen.

Faced with dire financial data, automakers have announced adjustments to their annual targets. On August 7, Toyota significantly revised its full-year operating profit forecast downward, from 3.8 trillion yen to 3.2 trillion yen; Audi also lowered its full-year financial forecast, adjusting its operating profit margin forecast from the previous 7% to 9% to 5% to 7%.

Simultaneously, the giants have pointed the finger of blame for the decline in profits at tariffs.

As one of the automakers with the most significant decline in net profit, Ford cited the impact of tariff adjustments as higher than expected. The "tariff war" initiated by the United States in April this year had a profound impact on the global automotive industry, and its effects have lingered to this day. Mazda, Toyota, Audi, and others also cited US tariffs as the core dragging factor.

The tariff war initiated by the United States this April hangs like a sword of Damocles over the global automotive supply chain, becoming a direct burden that crushes the profits of multinational automakers.

Under the heavy pressure of tariffs, end product prices were forced to rise generally, suppressing consumers' willingness to buy cars. Simultaneously, vehicle enterprises' supply chain costs soared sharply. If they needed to cross tariff barriers to enter the market, the cost of core components increased significantly.

To avoid high tariffs, automakers had to hastily initiate a deep restructuring of the global supply chain.

Porsche is considering transferring some production steps from Germany to the United States; BMW has accelerated the relocation of some MINI production lines from the UK to China in recent years; Stellantis is also adjusting its European factory layout... However, production transfer is no easy task.

Site selection, construction, equipment commissioning, worker recruitment and training, and supply chain localization reshaping of new factories all require substantial capital investment and time. Even after the initial migration is completed, issues such as inefficient initial capacity ramp-up and unstable yield rates will continue to erode profit margins.

This hasty supply chain restructuring is an expensive and painful process fraught with uncertainties.

Beyond the explicit "bullet" of tariffs, the deeper "arrow" of profit erosion for multinational automakers stems from their own heavy historical burden and high investment costs in transformation.

On the one hand, traditional fuel vehicle businesses were once cash cows, but with the irreversible advancement of the global electrification wave, their market space has been continuously compressed, and sales and profit contribution rates have continued to decline.

However, the vast production capacity, redundant personnel, and fixed operating costs established around fuel vehicles are difficult to reduce instantaneously. The restructuring costs repeatedly mentioned in some brands' financial reports are precisely the cost of this structural adjustment. Closing redundant factories, laying off employees, and disposing of idle equipment all involve cash outflows of hundreds of millions of euros. These costs directly impact current profits.

On the other hand, massive investments in the future are urgent.

The Volkswagen Group plans to launch more than 20 electrified models in the Chinese market by 2027 and provide about 30 pure electric vehicle models by 2030. Mercedes-Benz, BMW, Toyota, and others are all pouring vast sums of money into the research and development of electrification platforms, battery technology, intelligent software-defined vehicle capabilities, and charging network layout. These investments cannot be converted into substantial sales revenue and profits in the short term but continue to consume cash flow like a black hole, illustrating the profit dilemma of enterprises in transition.

02 Seeking Change Amid Competition

The profit winter experienced by traditional multinational automakers is not accidental but an inevitable manifestation of the unprecedented changes in the automotive industry in a century. On the surface, it is a decline in profits, but in essence, it is the restructuring of the industrial structure - the core issue is no longer who earns less but the collapse of the established order.

Therefore, only those who can persevere in this marathon until the transformation is completed, scale effects emerge, and new business models mature can ultimately usher in a profitable spring. As for those enterprises that cannot adapt, they may face the risk of elimination or integration.

When the traditional profit model is shaken under multiple shocks, the strategic position of the Chinese market has never been more important.

Data shows that in the first half of this year, China's auto sales reached 15.65 million units, a year-on-year increase of 11%, far exceeding the global average of 5%. More importantly, China's share of the global auto market rebounded strongly to 36% in June this year, and the cumulative share in the first half of the year was as high as 33.8%. China's position as an important engine of the global auto market is further underscored.

Considering the importance of the Chinese market, the strategic layout of many multinational giants is accelerating.

For example, the Volkswagen Group is betting on China's electrification future and plans to densely launch new energy vehicle models; Ola Källenius, Chairman of the Board of Directors of Mercedes-Benz, clearly stated, "I am optimistic about the long-term development of the Chinese auto market"; Porsche, despite a nearly 30% year-on-year decline in deliveries in China in the first half of the year, will still put the newly upgraded Shanghai Jiading R&D center into operation in the second half of the year, demonstrating its determination to delve deeper into China.

This eastward shift in strategic focus is not merely driven by market size but also a comprehensive consideration of the industrial environment, supply chain efficiency, consumer acceptance, and policy guidance. Everyone recognizes that whoever can better grasp the pulse of the Chinese market and meet the needs of Chinese consumers is more likely to take the initiative in future global competition and find new profit support points.

During this period, we have witnessed round after round of competition among giants.

Toyota, BYD, and others continue to increase research and development efforts, and technological breakthroughs will determine the discourse power in the next stage. Simultaneously, with the potential trend of the European Union following up on tariff policies, automakers need to balance regional production (such as BMW's expansion of its Mexican plant) and cost pass-through. Reshaping the price system with "technology for all" and avoiding trade risks through localized production are the countermeasures.

As for whether there is "efficacy" and how good the "efficacy" is, it remains to be seen. But what we know is that when the profits of Porsche and others plummet, and Toyota loses trillions of yen in profits overnight due to tariffs, the collapse of the established order is announcing: The era of effortlessly winning the global market by relying on brand prestige is gone forever.

Editor-in-Chief: Li Sijia, Editor: He Zengrong

THE END