Chery Asserts Independence in Battery Manufacturing

![]() 06/11 2025

06/11 2025

![]() 659

659

In the new energy era, automakers must strive for cost control, technological superiority, and global influence. Self-developed batteries represent the key to achieving these goals.

Body

With the surge in new energy vehicle sales, Chery has embarked on an ambitious journey into the battery sector.

Recently, Chery Automobile announced that its Deyi batteries have successfully passed the GB 38031-2025 new national standard safety certification, dubbed the "strictest battery safety order in history," a full year ahead of schedule, despite the standard not yet being officially implemented.

The new national standard GB 38031-2025, "Safety Requirements for Traction Batteries Used in Electric Vehicles," will come into force in July 2026. It features an expanded test regimen, increasing from 18 to 24 items, and introducing rigorous new tests such as bottom impact and fast-charging cycle thermal runaway, making the standards more stringent and the testing more extensive.

Chery's engineering spirit remains unwavering. Of the 24 tests stipulated by the new national standard, Chery exceeds the standards in 10 tests and has added an additional 28 verifications for enhanced safety.

The rationale behind Chery's decision to venture into battery manufacturing lies in addressing the cost challenges of the new energy era, supported by a comprehensive strategic framework.

Refusing to be a mere battery assembler

Batteries account for a substantial portion of the total vehicle cost, ranging from 40% to 60%. Leading battery manufacturer CATL has maintained a gross profit margin exceeding 20% for an extended period, achieving an average daily net profit of RMB 140 million in 2024.

This profitability presents a significant challenge for many automakers struggling with losses. Naturally, the trend of automakers developing their own batteries is intensifying, and Chery's choice to follow this path is not surprising.

The suitability of automakers developing their own batteries was earlier discussed in the context of Geely's battery strategy. The primary determinant remains the automaker's sales volume. The battery industry is capital-intensive and requires high R&D investment. Citing BOCI International's research, when battery prices are high, automakers with annual sales exceeding 400,000 vehicles can achieve a gross profit margin of around 10% by establishing their own battery factories. However, if battery prices drop below 0.5 yuan/Wh, the positive impact on gross profit margins from in-house battery production significantly diminishes.

In 2024, Chery's new energy vehicle sales reached 580,000 units, marking a year-on-year increase of 232.7%, surpassing the "10% gross profit line" threshold of 400,000 units mentioned in the analysis. In the first five months of this year, Chery maintained a robust growth rate, with sales reaching 287,800 units, representing a leapfrog growth of 111.5%.

However, even with this growth, Chery's new energy vehicle models account for less than 30% of total sales, below the industry average, indicating significant potential for further growth in this segment.

While time will tell if automakers can successfully develop their own batteries, industry insiders warn that delaying investment may result in missed opportunities.

Given Chery's sales volume, entering the battery industry is a worthwhile endeavor. Moreover, automakers with in-house battery technology are not subjected to "exorbitant prices" from external battery suppliers.

It is noteworthy that following the implementation of the new national standard in July 2026, battery safety will become a critical threshold. Currently, the industry average for test items stands at approximately 30, while Chery's 52 items elevate safety standards to an "unprecedented level," potentially increasing technological upgrade costs for smaller manufacturers. This shift will herald a new round of restructuring in the domestic battery market, presenting an opportune moment for Chery.

Furthermore, Chery sets battery safety standards far stricter and more comprehensive than national benchmarks. This rigorous approach reflects Chery's global ambitions, with products exported to over 110 countries and safety verifications encompassing diverse and complex working conditions worldwide. For instance, domestic regulations do not include standards for vehicle rollover tests, prompting Chery to conduct such tests for various models based on American standards.

These measures ensure that Chery's battery technology is both "downwardly compatible and upwardly breakthrough."

Currently, Chery is not only China's leading automaker in terms of exports but also boasts the most global "five-star safety" verifications among independent brands, with 41 models receiving various global evaluations such as China NCAP, Euro NCAP, ASEAN NCAP, and six-dimensional electrical safety.

This technical strategy is already bearing fruit. In the first five months of this year, Chery's cumulative export sales reached 443,900 units, continuing to rank first among Chinese automakers in exports. Safety endorsements are also paving the way for Chery to penetrate the European high-end market, potentially enabling this "engineering-focused" brand to shed its cost-effective label.

For Chery, developing its own batteries is an inevitable strategy to compete in cost control, technological definition, and global discourse power in the new energy era. This is a "battery war" that Chery must fight and win.

Reducing supply chain dependency

Chery's battery business strategy can be described as "walking on two legs": one focused on in-house R&D and manufacturing, and the other on collaboration with industry giants.

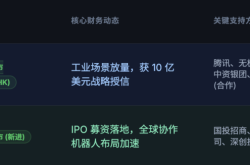

Since 2022, Chery has established Deyi Energy, a dedicated battery company responsible for cell R&D and production, while Qida Power focuses on battery pack and system integration, keeping core processes in-house. In 2024, the establishment of Anhui Qida and Shijiazhuang Qida significantly accelerated Chery's battery network deployment. Simultaneously, Chery collaborates with other partners, including joint development with leading battery companies like CATL.

To develop its own batteries, Chery has invested heavily in factories and industrial chains, particularly in Anhui, to build capacity.

The total investment in the Tongling Zongyang battery base exceeds RMB 10 billion. The second phase alone plans for a capacity of 17GWh, with 7 production lines dedicated to prismatic lithium iron phosphate batteries, including 100Ah cells for range extenders and 125Ah pure electric cells for 800V platforms, scheduled for full operation in April 2026. The Wuhu base focuses on R&D, with an investment of RMB 2.81 billion in pilot lines and testing centers to support technological iteration.

In terms of technological R&D, Chery has set new safety standards. It has established a "4+4+2" safety system encompassing mechanics, electrochemistry, environment, and thermal management. It has even created test items far exceeding national standards, such as 25mm/s high-speed needle puncture and 30% large-area extrusion deformation. The Wuhu Automatic Testing and Experimentation Center has invested nearly RMB 200 million in digital testing, innovating with a high-flashpoint ADSE electrolyte formulation to increase the upper threshold for thermal runaway (T1/T2).

The production process is meticulously controlled to achieve "PPB-level precision" (a precision of a few parts per billion), with 69 dust removal devices on a single production line to strictly prevent foreign objects, as even a single dust particle can cause internal short circuits, leading to thermal runaway and spontaneous combustion.

At the product level, Chery unveiled the Kunpeng battery brand at the 2024 Global Innovation Conference, comprising three major series: prismatic lithium iron phosphate (120-160Wh/kg), prismatic ternary (140-200Wh/kg), and large cylindrical ternary (140-240Wh/kg), all featuring leading indicators. Kunpeng batteries support 6C fast charging and over 3,000 charge cycles, achieving directed pressure relief in one second through a multi-sectional energy absorption design.

Notably, the large cylindrical battery targets a range of 1,200 kilometers, significantly ahead in terms of indicators, though mass production is still some time away.

Even more ambitious is Chery's solid-state battery roadmap, aiming to install solid-state batteries in 2026 and launch them in batches in 2027, demonstrating cells that remain functional after chamfering. However, the industry remains cautious about whether this can be achieved on schedule. Even CATL, the leading automotive battery company, has been reserved in its public statements, suggesting only that small-scale production may occur by 2027. This underscores the global challenges regarding the cost and process stability of solid-state batteries.

While future technological developments remain uncertain, reviewing Chery's battery supply situation in recent years reveals a clear trend. Chery Automobile has consistently reduced the number of battery suppliers while increasing the models and quantities supported by its own battery factories.

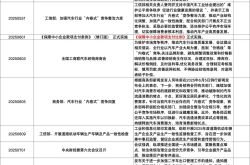

In 2023, Chery had six battery suppliers: CATL, Guoxuan High-Tech, Duofudo, Fudi Battery, EVE Energy, and its own battery factory, Deyi, which began supplying EV lithium iron phosphate batteries.

By 2024, this number had reduced to four suppliers: CATL, Guoxuan High-Tech, CALB, and Deyi, which had expanded to supply PHEV lithium iron phosphate batteries.

It is evident that Chery's battery supply system is undergoing a strategic transformation from multi-supplier dependency to "self-supply as the mainstay, with Ningde as an auxiliary." The future will determine whether Chery can redefine the automotive industry's discourse power with its moat of self-developed battery technology and cost advantages.