Figure 03: How Close Are We to the 'Era of Household Robots'?

![]() 10/13 2025

10/13 2025

![]() 416

416

Produced by Zhineng Technology

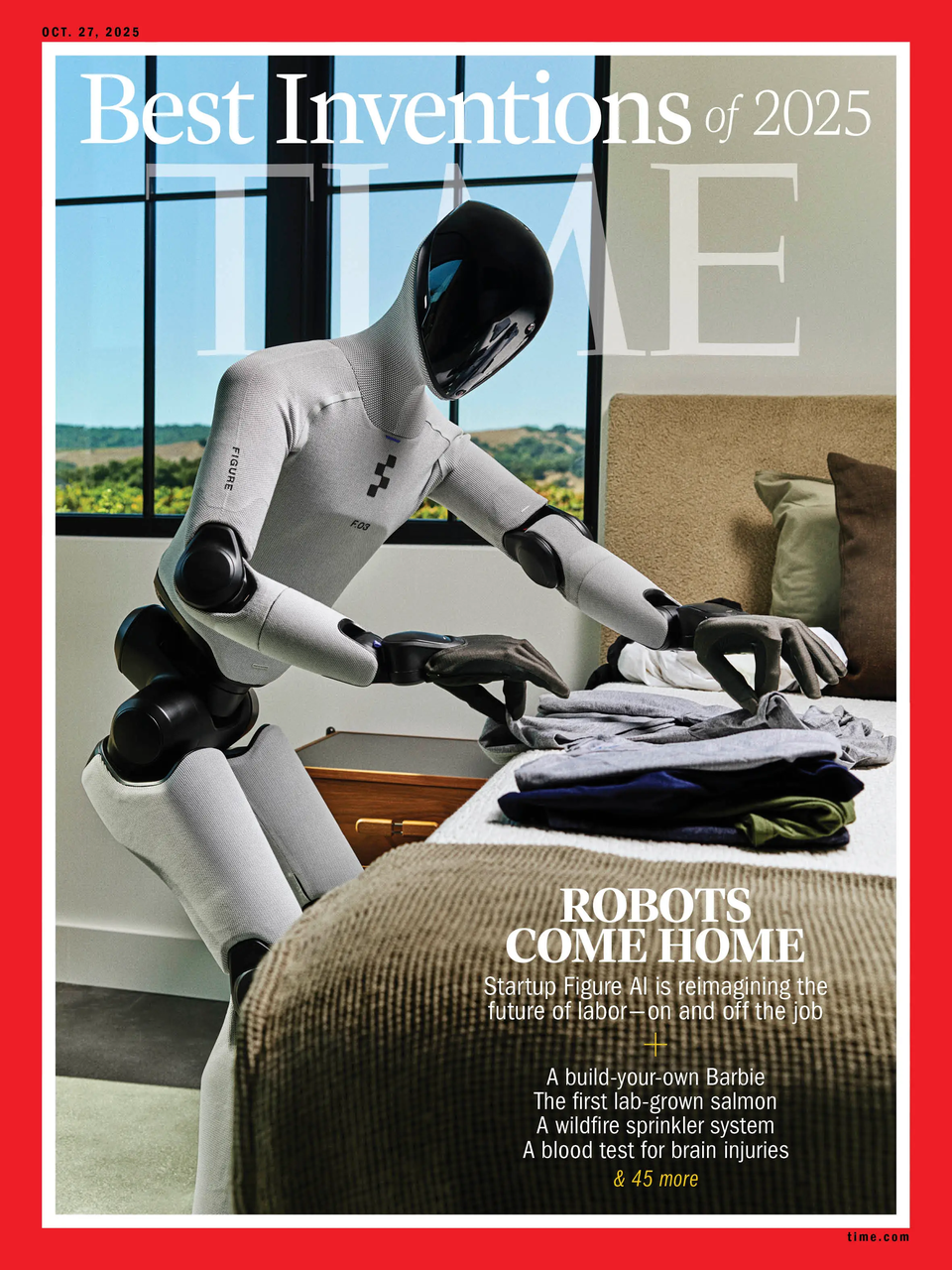

Featured on the cover of Time magazine, Figure 03 has captured widespread public attention. This robot is specifically designed to be compatible with the Helix neural network, tailored for household use, and built for global scalability.

Its ultimate goal is to evolve into a truly versatile robot capable of performing human-like tasks with precision, learning directly from human interactions. Founder Brett Adcock emphasized, "None of the actions in the promotional video were remotely controlled." Does this mark a significant technological milestone?

01

Technological Enhancements of Figure 03

Compared to its predecessors, like Figure 02, Figure 03 has undergone more comprehensive upgrades in key technologies.

● At the perception level, Figure has doubled the frame rate of its visual system, reduced latency to one-fourth of the original, and incorporated wider-field-of-view cameras.

This enables the robot to respond more swiftly when handling dynamic scenes and tracking fast-moving objects. Additionally, palm-mounted cameras and fine tactile sensors are integrated into the hand design, capable of detecting pressure changes as slight as 3 grams. This allows the robot to handle fragile objects, such as eggs and glass bottles, with greater adaptability and reduced error rates.

● In terms of control architecture, Figure's AI system, Helix, plays a pivotal role by integrating the entire "vision-decision-action" process, rather than merely serving as an auxiliary tool for planning or execution.

By fusing visual perception, semantic understanding, and motion control, it aims to achieve "understanding-based operation" of the environment. The robot will not just "see objects" but will also determine how to operate safely and effectively based on the context.

● Safety and soft design enhancements:

◎ Figure 03 has been optimized in terms of outer shell materials, structural design, and motion limitations. The robot's exterior features foam and soft textile coatings to minimize the risk of "collision injuries."

◎ It weighs approximately 9% less than the previous generation, enhancing its agility in household environments.

◎ The battery has received UN38.3 certification and supports wireless charging. The design includes detachable and washable covers, as well as replaceable shells, making it more suitable for home use and indicating the product's transition from an industrial prototype to a lifestyle device.

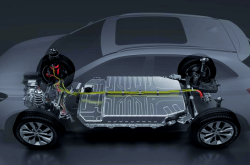

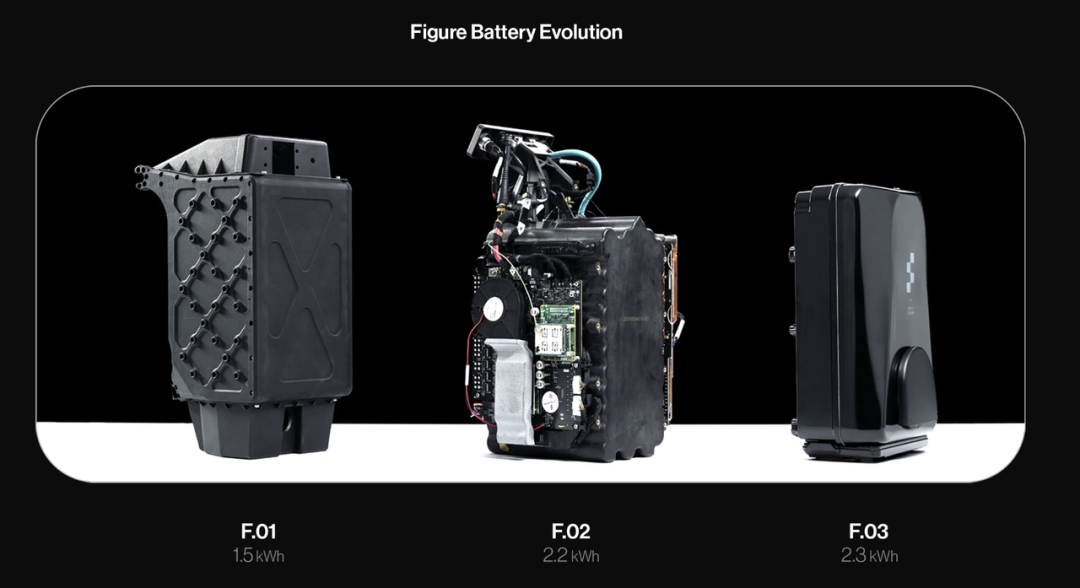

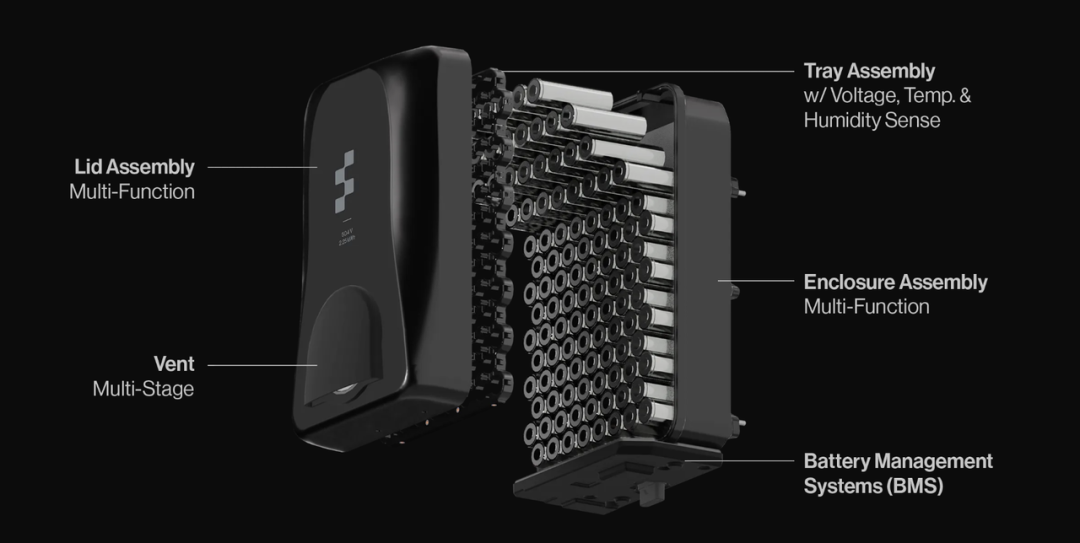

Figure has announced that the F.03 battery has been upgraded to its third generation, boasting a 94% increase in energy density. It is directly embedded in the torso, enhancing safety and interference resistance.

It excels in performance, safety, cost, and scalability, designed for mass production on the BotQ production line with an annual capacity of 12,000 units.

◎ 2.3 kWh capacity, supporting 5 hours of continuous operation under peak loads;

◎ Record-breaking compact volume-to-mass efficiency, achieving the highest energy density;

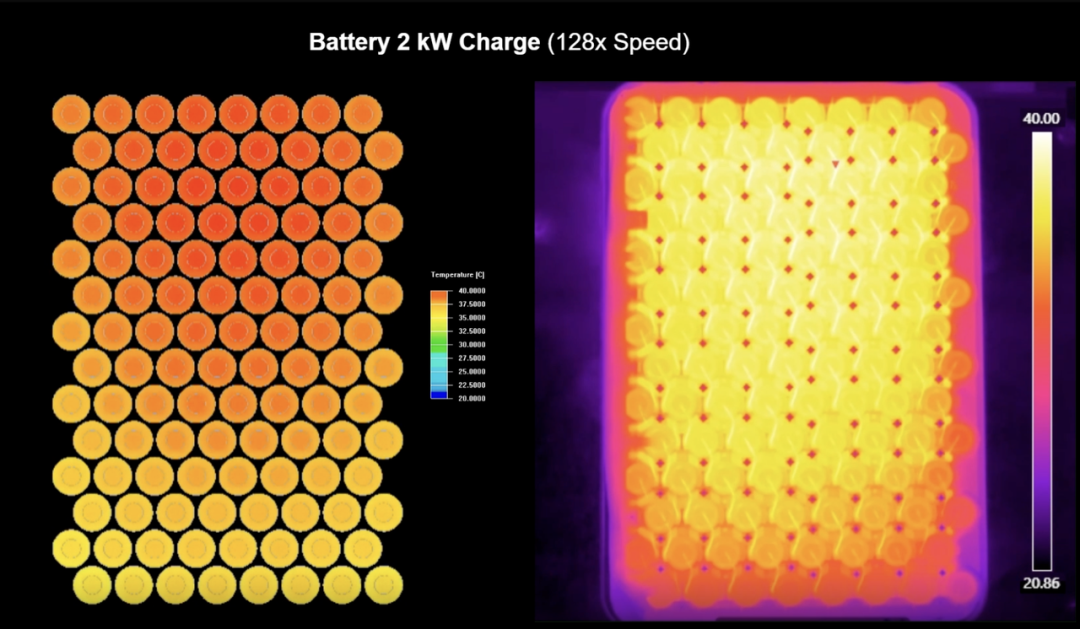

◎ 2 kW fast charging with an active cooling system;

◎ Custom BMS for monitoring battery health, optimizing performance, and preventing failures;

◎ Multi-layer safety architecture certified by UN/UL;

◎ Reliability verified through rigorous environmental/mechanical/electrical testing;

◎ Cost reduced by 78% compared to F.02;

◎ Mass production of components with an efficient assembly process.

Safety is Figure's Top Priority

◎ The BMS integrates sensors/switches/fuses to prevent overcharging/over-discharging/overheating/short circuits;

◎ Battery cells withstand UN/UL/IEC abuse tests (such as crushing/impact/overcharging/heating), with built-in dual fusing mechanisms;

◎ Interconnect geometry with fused components;

◎ Packaging layers control thermal events without external flames, and single-cell catastrophic failures will never catch fire, achieved through one year of thermodynamic modeling and physical testing iterations.

● In manufacturing and scalability, Figure has established its own production base, BotQ, and implemented robotic autonomous assembly processes within it.

BotQ aims to produce 12,000 robots annually, with plans to expand to a larger scale in the coming years.

By replacing traditional manual and CNC machining with molding, injection molding, and stamping, Figure strives to bring unit costs down to an acceptable range, enabling robots to transition from high-cost experimental products to potentially marketable commodities. This lays a relatively solid system foundation for Figure 03.

From perception and control to safety and production, this represents a blueprint for the path "from laboratory to product."

While Helix has demonstrated astonishing behavioral capabilities in demonstrations, its performance in real, uncontrollable environments is difficult to assess. Power consumption management, heat dissipation control, and energy density remain bottlenecks during continuous operation and high-load tasks.

02

Product Positioning

Figure positions Figure 03 as a "general-purpose humanoid robot" designed for both household and commercial scenarios.

The underlying assumption is that if a robot can operate seamlessly in the highly complex and disordered household environment, it will also be more adaptable in standardized environments such as logistics centers, supermarkets, warehouses, and hospitals.

This is a strategic approach: the household environment is the toughest "challenge" to overcome. Once mastered, other scenarios become relatively easier.

From real-world demonstrations, Figure 03 has shown some proficiency in tasks like folding clothes, clearing tables, organizing kitchen utensils, and loading dishwashers.

However, unexpected interferences may occur in actual environments: differences in furniture arrangements, unintended obstructions, clutter, lighting variations, and ground slippage can all disrupt the robot's perceptual and control stability.

The initial commercialization path is more likely to adopt a "semi-controlled environment + assisted operation" model. Figure 03 will struggle to be fully autonomous in truly unsupervised household scenarios but may be more feasible as a service, commercial, or assistive robot in quasi-structured environments (such as restaurants, factories, warehouses, and nursing homes).

For robots to become "consumer-grade devices," cost is a critical factor. Even with Figure's goal of producing 12,000 units annually, it must face pressures from component costs, assembly processes, after-sales maintenance, and logistics distribution.

While costs may decrease under economies of scale, initial pricing is likely to exceed acceptable levels for the general public, limiting Figure 03 to niche markets such as "high-net-worth households" and "commercial institutions."

The maintenance and update costs after robot deployment cannot be overlooked. Hardware failures, software upgrades, part replacements, sensor drift, and calibration error corrections will all be high hidden costs in the early stages.

Robot companies cannot rely solely on "closed platforms" to attract developers and upstream-downstream resources. Figure has previously collaborated with OpenAI, utilized NVIDIA toolchains, and openly discussed the integration of its AI models, simulation platforms, and control systems.

As a physical product, robots cannot avoid safety, privacy, and ethical issues.

Figure must build multi-layer safety mechanisms in engineering design:

◎ Collision detection, behavior auditing, permission control, and fault backups; establish strict privacy protection and liability boundaries in commercial strategy;

◎ Provide transparent interaction interfaces and error correction mechanisms at the user experience level.

Mistakes or "AI accidents" could have severe consequences, making this a challenging endeavor.

Summary

The evaluation of Figure 03 adopts an attitude of both anticipation and caution. Simultaneous upgrades in perception, control, safety, and manufacturing have taken a significant step forward for general-purpose humanoid robots.