Alumnus of East China University Launches Business in Wuxi: Pioneering Core Components for Humanoid Robots, Securing Over 100 Million Yuan in Investments

![]() 10/14 2025

10/14 2025

![]() 418

418

The robot upstream components sector is experiencing a surge of fresh opportunities.

Recently, Wuxi Cancer Intelligence Drive Technology Co., Ltd. (Cancer Intelligence) declared the successful closure of its Series A funding round, amassing nearly 100 million yuan. This round was led by the strategic investment arm of Ecovacs, a frontrunner in robotic vacuum cleaner production.

Cancer Intelligence equips robots with the essential 'bones and muscles connections'—harmonic reducers, micro low-voltage drivers, encoders, and force sensors. These components are highly integrated into humanoid joint modules, ready for direct assembly.

Through these modules, robotic arms become more lightweight, robust, and easier to incorporate, catering to manufacturers of humanoid robots, industrial collaborative arms, and specialized robots. They tackle the engineering hurdles of achieving simultaneous optimization in joint torque, precision, volume, and integration.

Cancer Intelligence not only provided the upper limbs (excluding hands) for the world's inaugural explosion-proof humanoid robot, 'Tiankui 1,' but also secured the contract for the intelligent inspection robot project at Harbin Electric Machinery Company Limited. In April of this year, it was honored as the 'LeadeRobot 2025 Core Supplier for Humanoid Robots.' To date, it has supplied 1,320 specialized modules for humanoid robots.

- 01 -

Established in 2019, Cancer Intelligence was founded by Dr. Zhao Wei, a Ph.D. graduate from Southeast University. Zhao Wei's foray into robotics began during his graduate studies, where he participated in factory automation projects, igniting his passion for leveraging technology to enhance production safety. He later competed in the prestigious global RoboCup robotics competition.

In 2006, Zhao Wei embarked on his entrepreneurial path, initially focusing on the production of complete robotic systems. He soon realized that dependence on foreign core components posed a significant industry bottleneck—harmonic reducers, often dubbed the 'joints' of robots, were long hindered by overseas technology. This insight spurred him to pivot towards component R&D, aiming to overcome these 'choke point' challenges.

In April 2019, Zhao Wei founded Cancer Intelligence in the Wuxi Economic Development Zone, with harmonic reducers and integrated joint modules as the focal points of R&D. During the nascent stages of development, the team meticulously refined a component with a mere 12-millimeter diameter through numerous iterations. They enhanced the payload capacity of robotic dual arms from 5 kilograms to 50 kilograms, establishing a new industry benchmark of '1 kg arm weight supporting a 50 kg load.'

In early 2025, the team supplied core upper limb components (excluding hands) for the world's first explosion-proof humanoid robot, 'Tiankui 1,' enabling the robot to achieve a shoulder limit load of 100 kilograms and an end-effector load of 20 kilograms, substantially outperforming industry norms.

- 02 -

The industry of 'robotic transmission systems and precision reducers,' in which Cancer Intelligence operates, has transitioned from its infancy to a phase of accelerated domestic substitution.

In its early days, the industry was dominated by imported products from Europe, the United States, and Japan, which, while offering high precision and longevity, were marred by exorbitant prices and lengthy delivery times. The industry's rise coincided with China's burgeoning demand for industrial and service robots, prompting domestic suppliers to rapidly bridge the gap. In recent years, with the explosion of new downstream demands, such as humanoid and service robots, the technology and production capacity of harmonic reducers and integrated joints have become pivotal for the industrial chain to achieve mass production.

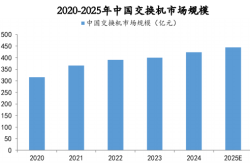

Industry reports indicate a steady expansion in the market size for harmonic reducers and robotic transmission systems. In 2023, China's harmonic reducer market reached a scale of several billion yuan, and in 2024, the robotic transmission system market also attained a similar magnitude. Meanwhile, the global market has long been dominated by a handful of foreign manufacturers, but the scope for domestic substitution is on the rise.

Current market challenges primarily revolve around three areas: Firstly, the cost and yield of high-performance joints—precision machining and assembly requirements are stringent, and yield rates impact delivery. Secondly, the lengthy integration and customization cycles necessitate significant system-level debugging by complete machine manufacturers. Thirdly, the conflict between high torque/high precision and lightweight design.

Mainstream solutions can be broadly categorized into two: One category continues to rely on imported or mature split-type high-precision reducers (such as those from foreign brands like Harmonic Drive Systems and Nabtesco), while the other category, championed by domestic manufacturers, emphasizes localization and modularization. Integrated joints and servo integration are increasingly being adopted by complete machine manufacturers. Cancer Intelligence reduces complete machine integration costs through modularization and integration, moving towards a 'plug-and-play' component supply model.

Currently, the high-end market remains highly concentrated among formidable foreign players. However, with the dual enhancement of technology and production capacity among domestic manufacturers, the industry is witnessing a landscape of 'leading enterprises + multiple specialized mid-tier companies.'

The field of harmonic reducers has long been dominated by a few foreign enterprises, but domestic representative companies such as Leader Harmonic Drive have witnessed their market shares continuously ascend in recent years. Overall, the supply of robotic components is transitioning from a 'period of supply shortage' to a 'period of growth with intensified competition': Downstream applications (industrial robots, semiconductor equipment, humanoid and service robots) are exhibiting differentiated growth. Certain segments (such as high-performance joints for humanoid robots) still face supply shortages in the short term. However, in the long run, with localization and production capacity expansion, competition will become fierce.

For companies like Cancer Intelligence, which focus on a 'joint module + integration' delivery model, their differentiation lies not in the performance of a single component but in the deep integration of functions such as speed reduction, driving, encoding, and force sensing. This shortens complete machine debugging time and enhances secondary development friendliness—a direct allure for complete machine manufacturers and one of the reasons why Ecovacs, as a downstream giant, is willing to make strategic investments from the industrial end.

- 03 -

Looking ahead, the development of new technologies will continue to reshape this niche sector.

With the maturation of force sensors, integrated encoders, micro high-efficiency servos, and software-hardware cooperative control algorithms (especially AI-based motion planning and coordinated control), robotic joints will gradually evolve from 'mechanical transmission units' to 'intelligent execution units.'

This implies that complete machine manufacturers will have an increasing demand for 'plug-and-play' joint modules with self-diagnosis and cloud adaptation capabilities. Manufacturers can then allocate more resources to perception and intelligent application layers while entrusting motion execution to component suppliers with scalable ecosystems.

For companies like Cancer Intelligence, the core opportunity lies in leveraging technological accumulation in the upstream industrial chain, combining modularization, software capabilities, and scalable manufacturing to capture a higher value share in the future mass production of humanoid robots, collaborative robots, and specialized robots. Industry reports also highlight that subfields such as sensors, vision, and force control will emerge as the fastest-growing segments in the future, creating substantial incremental space for upstream and downstream enterprises.

Cancer Intelligence's nearly 100 million yuan Series A financing reflects a strategic shift by complete machine manufacturers, moving from 'grasping core applications' to 'grasping core component supplies.'

This article does not constitute any investment advice.