Post-90s Entrepreneur from Weifang, Shandong, Leads Humanoid Robot Company: Secures RMB 1.5 Billion in Funding, Eyes IPO with Tencent’s Support

![]() 10/27 2025

10/27 2025

![]() 614

614

Recently, another humanoid robotics firm has successfully closed a significant funding round.

On October 22, Shenzhen-based Leju Robotics raised nearly RMB 1.5 billion in its Pre-IPO funding round, with contributions from 15 institutions, including Shenzhen Investment Holdings Capital, Shenzhen Longhua Capital, and Qianhai Infrastructure Investment. According to CVINFO data, this funding stands as one of the largest single financing events in the humanoid robotics sector for the year.

Leju Robotics offers two distinct product lines: 30-70cm mini bipedal robots tailored for the education market, which are used by nearly 5,000 primary and secondary schools and vocational colleges across the country; and full-sized humanoid robots designed for industrial and research applications, already deployed in industrial settings like BAIC Off-Road.

Leju Robotics' push for an IPO has drawn significant industry attention to two emerging opportunities in humanoid robotics:

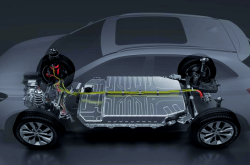

1. Collaborative innovation across the industrial chain and breakthroughs in new technologies, such as 5G-A remote operation technology and specialized solid-state batteries for robots, which enhance environmental adaptability and endurance.

2. Expansion into emerging markets like Southeast Asia and Europe. With manufacturing labor costs in Southeast Asia rising by 8% annually and Europe's aging population exceeding 20%, the demand for humanoid robots is becoming increasingly urgent. Leju has initiated market research in Southeast Asia, planning to launch simplified industrial robots suited to local conditions by 2026.

- 01 -

Like Unitree Robotics founder Wang Xingxing, Leju Robotics founder Leng Xiaokun is a post-90s entrepreneur, born in Weifang, Shandong in 1992.

Leng won national youth robotics competitions during his secondary school years and was recommended to the Computer School at Harbin Institute of Technology, where he repeatedly secured first prizes in national robotics championships.

In 2016, Leng led nine HIT classmates to Shenzhen to embark on their entrepreneurial journey. At that time, the humanoid robotics industry faced a core challenge: the 'disconnection between technology and industrialization.' Laboratory prototypes costing over RMB 1 million were difficult to mass-produce, while toy-grade products lacked practical value, with core components reliant on imports.

Leng proposed a 'mini-first, full-sized follow' strategy: first achieving industrialization with mini robots to recoup funds, then tackling core technologies for full-sized models. This approach became crucial in breaking industry bottlenecks.

In July 2016, they secured RMB 10 million in angel investment from Songhe Capital and finalized the mass production of the first-generation mini bipedal robot 'Aelos' within a month.

In 2017, Tencent's RMB 50 million strategic investment facilitated upgrades to educational robots, which quickly entered a thousand schools.

When developing the full-sized humanoid 'Kuafu' in 2018, they encountered global supply chain immaturity, necessitating cross-regional procurement of core components. The first prototype cost over RMB 3 million yet struggled with mass production, prompting the team to pursue core component localization.

In 2023, the 'Kuafu' robot, equipped with OpenHarmony OS, was launched, capable of jumping and navigating multi-terrain environments.

In January 2025, the 100th full-sized humanoid was delivered to BAIC Off-Road, establishing Leju as a domestic leader in delivery volume. In March, they partnered with China Mobile and Huawei to launch a 5G-A humanoid robot, marking a successful transition from technology to commercialization.

- 02 -

The humanoid robot market is on the brink of explosive growth. GGII data indicates that Chinese humanoid robot sales surpassed 4,000 units in the first half of 2025, with projections reaching 7,300 units annually.

However, the industry faces three key challenges: high costs of core components, inadequate scenario adaptability, and insufficient mass production capabilities. Mainstream solutions are divided into 'educational mini' and 'industrial full-sized' categories, with Leju being one of the few firms achieving large-scale commercialization in both.

In terms of the competitive landscape, the top three firms accounted for 79.63% of the market share in the first half of 2025 (GGII statistics), led by Unitree Technology (51.72% market share, expanding from quadrupedal to humanoid robots), Ubtech (16.86%, focusing on service scenario humanoids), and Zhiyuan Innovation (11.06%, targeting high-end research full-sized robots). Current market demand far exceeds supply, with global sales projected at just 12,400 units in 2025 (Frost & Sullivan forecast), unable to meet industrial and educational needs.

Compared to competitors, Leju's core differentiation lies in its 'full-industry-chain ecosystem + dual-scenario parallel operations.' According to its 2025 supply chain report, Leju controls core components through investments in Quanzhibo (joint parts) and Liju Power (motors), while partnering with Dongfang Precision to establish mass production lines, addressing industry-wide mass production challenges. Simultaneously, it maintains parallel operations in educational and industrial scenarios, using educational robots for stable cash flow and full-sized products to secure future markets.

From a technological evolution perspective, humanoid robots are entering a phase of multi-technology convergence breakthroughs. In core motion control, the fusion of Model-Based and Reinforcement Learning (RL) algorithms has become mainstream. Traditional single algorithms struggle with complex scenarios due to reliance on preset models or insufficient stability from trial-and-error methods. The combined 'cerebellum' system enables rapid adaptation to unknown environments.

After applying this technology, Leju's 'Kuafu' robot reduced terrain adaptation error rates to 3.2%. 5G-A technology has broken operational boundaries, with Leju's jointly developed 5G-A humanoid robot enabling remote engineer operation of chassis welding at BAIC's factory.

In energy supply, mainstream lithium batteries offer under 4 hours of endurance, but solid-state batteries and wireless charging technologies are addressing this. GGII predicts that over 30% of mid-to-high-end products will adopt solid-state batteries by 2026, extending endurance to 8-10 hours and reducing charging times to under 1 hour. Leju has partnered with CATL for next-generation 'Kuafu' robots.

- 03 -

Driven by new technologies, future opportunities in the humanoid robotics industry are concentrated in three areas:

1. Vertical scenario penetration: With over 40 million disabled elderly in China (Ministry of Civil Affairs data) and a 5 million caregiver shortage, the elderly care companion robot market is projected to exceed RMB 20 billion by 2028. In smart logistics, JD.com and SF Express have piloted autonomous loading/unloading robots.

2. Global expansion: Rising manufacturing labor costs in Southeast Asia (8% annual increase) and Europe's over 20% aging population are driving robot demand. Leju has initiated Southeast Asia market research, planning to launch simplified industrial robots adapted to high-temperature/humidity environments by 2026.

3. Industrial chain collaborative innovation: Localization of core components is accelerating, with GGII projecting a 40% cost reduction for domestically produced high-precision joints by 2027. This will lower overall machine costs and attract SMEs, creating a 'technology breakthrough - cost reduction - demand explosion' cycle.

This article does not constitute investment advice.