Dexterous Hand Manufacturers: Ascend Beyond Component Suppliers

![]() 10/31 2025

10/31 2025

![]() 459

459

Editor's Note: The true 'dexterity' of robots lies in the final centimeter—the dexterous hand. Integrating mechanics, sensing, and AI, it transcends traditional gripper limitations, evolving from industrial tools into autonomous 'human-like intelligent agents.'

Amid the surge of embodied AI, dexterous hands have emerged as a focal point. Xinghe Pinlv launches a special series on dexterous hands, delving into the technological revolution centered around 'touch,' 'manipulation,' and 'creation.'

Beyond cutting-edge joint technologies, we explore deeper reflections on 'capability boundaries' and 'human-machine symbiosis' amidst technological fervor.

Together with visionaries, we aim to unlock the ultimate frontiers of human-machine collaboration that these 'dexterous hands' can reach.

Author | Mao Xinru

As the premier robotics conference held in mainland China in two decades, IROS 2025 has injected fresh momentum into the embodied AI industry this autumn.

Despite being an academic forum, it drew over 160 domestic and international exhibitors, even featuring robot parades to showcase their capabilities.

Beyond the usual focus on humanoid robots, the event uniquely gathered over 15 leading and emerging dexterous hand players from home and abroad.

Veterans included Shadow (international), Intelligent Actuator (INROBOT), and OYHand Technology (domestic); newcomers featured Sharpa (Singapore), Dexterous Intelligence, and Yuansheng Intelligence (domestic).

At the venue, these manufacturers demonstrated remote operation capture, card playing, instant photo-taking, and long-sequence interactions. Yet, behind these captivating demos lies a pressing challenge:

Crafting a dexterous hand for 'impressive displays' is straightforward; enabling stable, intelligent real-world task execution remains elusive.

Real-World Challenges: From 'Precision Hardware' to 'Intelligent Operation'

The dexterous hand, a critical determinant of robotic operational limits, is dubbed the 'last centimeter' of humanoid robots. Much like human capability hinging on hands, a robot's integration into human environments depends on its dexterity.

Both Elon Musk and Figure AI CEO Brett Adcock have admitted that developing a truly functional dexterous hand rivals the technical challenge of building an entire robot.

However, this high technical threshold contrasts sharply with industrial realities.

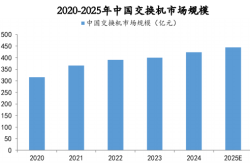

According to ROBO Global's annual report, only ~15% of 2024's global robotics investments flowed into specialized actuators and end-effectors, with dexterous hands—a niche segment—receiving even less attention.

This reflects capital markets' preference for platform-potential 'brains' or complete robot solutions over component-level dexterous hands.

Two entrenched realities underpin this undervaluation.

First, hardware-centric path dependency. Most dexterous hand firms originated in core components like coreless motors, industrial grippers, or medical bionic hands, carrying strong hardware DNA.

This background naturally labels them as hardware vendors when entering the embodied AI space.

More critically, these firms rely on proprietary R&D in core components (e.g., coreless motors, sensors, micro-servo cylinders), fostering a focus on hardware iteration—minimizing size, enhancing stability, reducing costs, and breaking the 'cost-performance-reliability' trade-off.

Over time, both internal R&D inertia and external perceptions have confined them to hardware supplier roles.

Second, most dexterous hands remain lab tools or showcase exhibits, with few deployed in industrial or commercial service tasks.

Simple, low-cost grippers with stable control dominate real-world applications, reinforcing the stereotype of dexterous hands as exquisite toys or research props.

These two constraints form a self-reinforcing loop: hardware-focused players struggle to escape parameter-driven thinking, causing talent imbalances; limited real-world deployment hinders industry recognition of systemic value.

This 'hardware-heavy, scenario-light' loop has drawn academic attention.

An MIT scholar noted in a review that the dexterous hand field overly focuses on hardware competition, neglecting concurrent development of operational intelligence.

Hardware is the body; data and algorithms are the soul that breathe life into dexterous hands. The industry's challenge isn't building better hands but enabling intelligent manipulation.

Breakthrough Key: Scarce Dexterous Manipulation Data

Enabling intelligent manipulation hinges on data.

In embodied AI, data-driven robot training is consensus. However, not all data equally teaches dexterous skills.

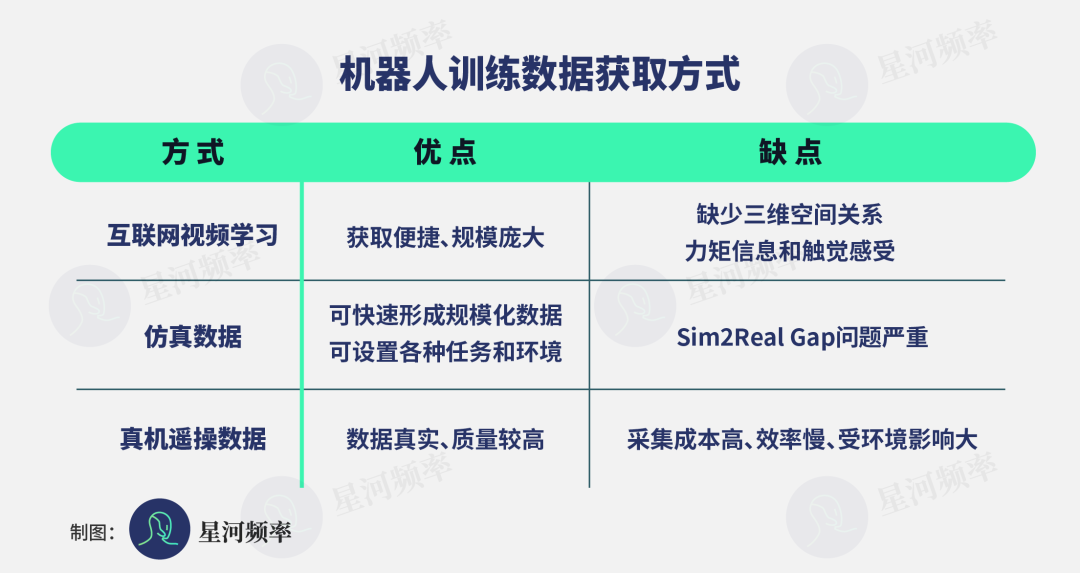

Currently, firms acquire robot training data via internet video learning, simulation-generated data, or human teleoperation, each with significant limitations. The industry now adopts a hybrid 'real + simulated data' approach.

As the industry grapples with data scarcity, an overlooked truth emerges: dexterous hand manufacturers are closest to high-quality manipulation data.

As designers and producers, they encounter rich real-world manipulation scenarios during R&D, testing, and client collaborations—from lab tests like pinching chips or twisting bottle caps to factory assembly trials or service-scene object handovers.

Throughout, sensors capture finger positions, forces, speeds, and object interactions in real-time. This data is gold for embodied AI.

Crucially, high-quality dexterous hand data includes force control details that robot manufacturers struggle to capture point-by-point—a domain where dexterous hand firms hold home-field advantage.

Each dexterous hand is a mobile data collector; manufacturers sit on an untapped 'data goldmine.'

Among players, Dexterous Intelligence mined this first, officially releasing and open-sourcing its large-scale human hand operation dataset, DexCanvas, in late September.

This move transcends the hardware supplier narrative, elevating them to builders of industry data infrastructure.

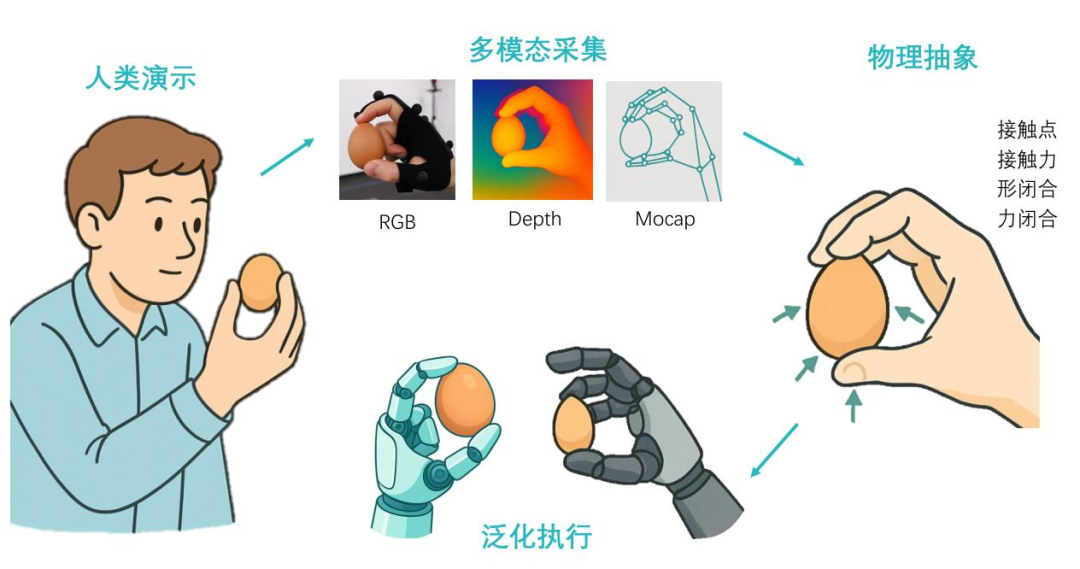

DexCanvas integrates over 1,000 hours of real human hand multimodal data (motion, vision, force) and 100,000+ hours of high-fidelity physics simulation data, with sub-millimeter trajectory precision.

For physical realism, its proprietary data pipeline ensures geometric and mechanical interactions align with real-world physics, narrowing the simulation-reality gap.

Technologically, DexCanvas anchors the 'Real2Sim2Real' loop. By injecting real-world data into simulations, it trains robust control models for efficient real-hand deployment, forming a self-reinforcing, data-driven cycle.

Most industry-driving is its full open-sourcing.

Via platforms like Hugging Face, Dexterous Intelligence shares this dataset globally, lowering research barriers and aiming to build a high-quality data ecosystem—positioning itself as an infrastructure contributor, not just a hardware competitor.

Open-Source Dataset Drives Industry Ecosystem Benefits

An open-source wave is sweeping embodied AI this year, marking a shift from isolated competition to ecosystem collaboration.

Open source harnesses collective intelligence, enabling free, multidirectional resource flow and efficient allocation, reducing industry-wide R&D costs and time.

MIIT officials note open source as vital for nurturing emerging industries and new productive forces.

DexCanvas's open-sourcing arrives at a pivotal moment, with multi-layered impacts.

First, it lowers barriers to dexterous manipulation research. Previously, high-quality data collection demanded costly equipment and complex processes, creating steep entry barriers.

Now, any team, regardless of size, can leverage DexCanvas to accelerate algorithm-to-reality cycles. Second, it provides urgently needed benchmarks and standards. The field long suffered from inconsistent data annotation, hindering algorithm generality and transferability.

DexCanvas adopts a 22-category human hand operation framework with unified physical attribute labels (e.g., force closure, form closure), offering a replicable data standard.

This standardization enables cross-team comparison, fostering orderly field development.

More critically, an open data ecosystem could decouple dexterous hands from proprietary data, spurring diverse solutions.

Under isolated competition, algorithms and hardware are tightly coupled, limiting cross-platform migration. DexCanvas, sourced from pure human demonstrations, provides a vendor-agnostic foundation for cross-platform skill transfer.

Researchers can innovate algorithms on various open models using DexCanvas data, then deploy them across hardware platforms. This collaborative ecosystem outpaces isolated corporate efforts.

However, open source isn't a panacea. It solves 'data availability' but raises new questions: how to sustainably update and maintain long-term dataset value, and ensure effectiveness in diverse industrial scenarios.

This demands more firms and institutions join the ecosystem, contributing data and refining standards for virtuous cycles.

Today, dexterous hand manufacturers stand at a crossroads:

Remain in the 'advanced component supplier' comfort zone, or leverage unique data advantages to build algorithmic and systemic capabilities, becoming indispensable drivers of embodied AI ecosystems.

Tearing off the label of "component manufacturer" is not just a change in the company's positioning, but also a restructuring of value. In the current era of deep AI integration, a single hardware module is no longer the pinnacle of value. Instead, the data streams and algorithms that drive hardware to become intelligent are the more precious elixirs.

Dexterous hand manufacturers hold the gateway to the gold mine. Whether they can truly strike gold depends on whether they possess the capability and courage to mine, refine, and utilize these data assets.

In the future, who will secure a place in this great melee will depend on who can not only create dexterous hands but also endow them with a wise soul.