Optical Communication Chips, Price Increase?

![]() 11/04 2024

11/04 2024

![]() 581

581

Due to the surging demand for artificial intelligence, Marvell, a major U.S. networking and optical communication chip manufacturer, recently issued a notice announcing a price increase across its entire product line starting from January 1, 2025, taking the lead in the wave of price hikes in the optical communication sector.

In a market scenario where even storage prices may decline, optical chips have boldly decided to increase prices starting next January. Why such boldness?

01

Expanding Scale of Optical Chips

The market has a decisive influence.

Optical chips are the fundamental components for converting optical and electrical signals, and their performance directly determines the transmission efficiency of optical communication systems.

Since their inception in 1998, optical modules have continually evolved towards higher data rates. From 1.25Gbit/s to 2.5Gbit/s, and then to 10Gbit/s, 40Gbit/s, 100Gbit/s, 100Gbit/s per wavelength, 400Gbit/s, and even 1T.

The higher the data rate and more advanced the optical module, the greater the proportion of the value of optical chips.

Today, the market for optical chips is continuously expanding and occupying an increasingly important position in various downstream applications. With the rapid development of communication technology, the optical chip market is showing strong growth momentum globally, primarily due to the increasing demand for high-speed, high-bandwidth, and low-latency communication in downstream applications. For instance, in data centers and cloud computing, high-density, high-performance optical interconnect solutions have become the core of infrastructure, and the application of optical chips in these areas is on the rise.

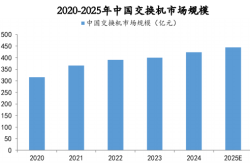

According to C&C Research, the global market size for optical chips used in optical communication was $2 billion in 2020 and is expected to reach $3.6 billion by 2025, with a CAGR of approximately 12.59%. According to Guanyan Information Consulting, China's optical chip market size is expected to reach $2.607 billion by 2025, with a CAGR of about 15.16% from 2020 to 2025. Additionally, optical chips play a crucial role in areas such as artificial intelligence and industrial automation. As AI technology continues to advance, the demand for ultra-large computing clusters is increasing, driving shipments of high-speed optical chips.

The AI optical chip Taiji developed by Tsinghua University uses light instead of electricity to process data, offering hundreds of times the energy efficiency of traditional electronic chips, making it suitable for complex AI tasks. Furthermore, the Shanghai Institute of Microsystem and Information Technology of the Chinese Academy of Sciences has developed high-performance photonic chip materials that can be mass-produced, providing a new foundation for the future information industry.

Recent application cases of optical chips in optical communication and optical computing focus on optoelectronic hybrid integration technology, especially co-packaged optics (CPO) technology, which has driven research and application in the field of optical communication. Companies like Intel are committed to enhancing computational efficiency by combining optical interconnects I/O with electrical processors and have achieved remarkable results. Although CPO still faces challenges, it is expected to gradually enter commercial use in the coming years, offering advantages such as reduced power consumption, increased integration, and lower cost per bit.

Ultraviolet optical communication utilizes photonic integrated circuit (PIC) technology, offering the advantages of reduced system size, power, and cost. Wei Tongbo's team has fabricated a monolithic integrated chip with a 450 nm wavelength visible light LED, waveguide, and photodetector using InGaN material with an asymmetric multiple-quantum-well structure, enhancing the optical coupling between the LED and PD.

Moreover, IBM researchers have made breakthroughs in using optical pulses to accelerate data transmission between chips, a technology that could boost supercomputer performance by over a thousand times. This technology significantly enhances supercomputers' computational capabilities; the fastest supercomputers currently reach speeds of up to 200 quadrillion instructions per second, and photonic technology could potentially increase this to one quintillion instructions per second.

Simultaneously, with the commercialization of 5G communication and the popularization of the Internet of Things, the application of optical chips in mobile communications, wireless networks, and smart devices is becoming increasingly important. Overall, the growth of the optical chip market and its increasing share in various downstream applications reflect the crucial role of optoelectronic technology in modern communication and information fields, as well as its indispensability in driving scientific and technological progress and social development.

02

First Move in the Market

As mentioned earlier, optical communication leader Marvell recently notified customers that its entire product line would increase prices starting from January 1 next year.

Marvell's move to initiate the price hike in the industry also reflects the "fanatical" market demand, echoing NVIDIA CEO Jen-Hsun Huang's previous statement that "market demand is insane," simultaneously sparking greater imagination for potential business opportunities in the optical communication industry chain.

Optical chip company Lumentum recently released its fiscal 2024 results, indicating strong demand for optical chips. Lumentum stated that the industry is facing a widespread shortage of indium phosphide lasers, and the company's indium phosphide capacity will be fully utilized until the end of 2025, resulting in overall supply tightness. The company's chip business bookings have reached an all-time high, and the company has invested $43 million this quarter to increase wafer fab capacity, expecting to see incremental capacity in the first half of 2025. However, in the short term, considering factors such as the wafer fab cycle, incremental capacity is relatively fixed.

Domestically, on October 21, the "Guangdong Province Action Plan for Accelerating the Innovative Development of the Optical Chip Industry (2024-2020)" was issued. It mentions accelerating research and development breakthroughs in key optical chip materials, strongly supporting the research, development, and manufacturing of key optical chip materials such as silicon photonics, compound semiconductors, thin-film lithium niobate, gallium oxide thin films, electro-optic polymers, flexible substrates, metasurfaces, optical sensing materials, electro-optic topological phase change materials, photoresists, and quartz crystals; and promoting the research, development, and manufacturing of key optical chip equipment. Efforts will be made to vigorously promote the research, development, and localization of key optical chip equipment such as etchers, bonders, epitaxial growth equipment, and optical vector network analyzers.

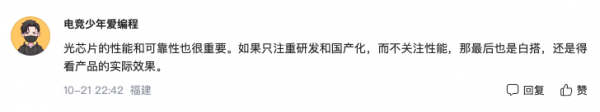

Regarding this, some netizens commented that the ultimate goal of localization is to achieve better results.

03

High Degree of Localization for Low to Medium-Speed Optical Chips

There is a high degree of localization for low to medium-speed laser chips, and the localization of high-speed laser chips is accelerating. In the field of optical chips with speeds of 2.5G and below, Chinese optical chip companies have basically mastered core technologies and possess a high localization rate. According to ICC's forecasts, in 2021, domestic optical chips accounted for over 90% of the global market share within this speed range. In the field of 10G optical chips, the localization of 10G optical chips varies depending on their technology and process, with some requiring higher performance and posing greater challenges.

In the field of optical chips with speeds of 25G and above, with the advancement of 5G base station construction, Chinese optical chip manufacturers have made some breakthroughs in 25G DFB laser chips used in 5G base station fronthaul optical modules. In 2021, the localization rate of 25G optical chips was approximately 20%. However, the localization rate for optical chips with speeds above 25G remains low at around 5%. Additionally, high-speed optical chip products used in data centers are still dominated by overseas manufacturers.

Localization has been achieved for some markets with speeds of 2.5G/10G, and there is significant room for import substitution in the 25G market. Overseas optical communication companies have accumulated core technologies and production experience through their early advantages, gradually forming a closed industrial loop and establishing high industry barriers. Domestically, there are relevant industrial policies for support, and enterprises are increasing investment in innovation, gradually giving rise to domestic optical chip enterprises such as Source Photonics, Yunling Optoelectronics, and Wuhan Minsemi.

Currently, breakthroughs have been made in the localization of 2.5G/10G laser chips, but the localization rate for 25G and higher-speed optical chips still largely relies on imports. According to ICC statistics, in the global market for DFB/FP laser chips with speeds of 2.5G and below in 2021, domestic manufacturers accounted for a higher proportion. Among them, the more advanced manufacturers with a market share exceeding 10% include Wuhan Minsemi (17% share), Zhongke Guangxin (17% share), Guanglong Technology (13% share), and Guang'anlun (11% share).

There is significant room for import substitution for products with speeds of 2.5G and above. Optical chips with speeds of 25G and above include 25G, 50G, and 100G lasers and detector chips. With the continuous development of 5G construction, China's optical chip manufacturers have made breakthroughs in 25G DFB laser chips used in 5G base station fronthaul optical modules, and optical module enterprises in the data center market have also begun to gradually adopt 25G DFB laser chips from domestic manufacturers. According to ICC statistics, the localization rate of 25G optical chips is approximately 20%, while the localization rate for optical chips with speeds above 25G is only 5%.

It can be said that high-speed products are still waiting. According to YJR, in 2021, DFB chips, VCSEL chips, and EML chips accounted for 42.1%, 29.2%, and 18.6% of the market share, respectively. From the perspective of localization development trends, China's high-power laser chips and some high-speed laser chips (such as 10Gbps and 25Gbps) have entered a stage of accelerated localization breakthroughs. However, optical detector chips and high-speed laser chips with speeds above 25Gbps are still in the early stages of import substitution, and there is vast potential for future localization improvements.

From a production perspective, the production process of optical chips includes five main stages: chip design, substrate manufacturing, epitaxial growth, die manufacturing, and packaging and testing.

Most Chinese companies primarily focus on the chip design stage, while global enterprises capable of mass-producing high-purity single-crystal substrates are primarily overseas.

Epitaxial growth/epitaxial wafers represent the most technically challenging aspect of the optical chip industry, with mature technologies primarily concentrated in Taiwan, the United States, and Japan. The die manufacturing and packaging and testing stages are mainly concentrated in Taiwan.

The production of optical chips employs a more comprehensive range of processes, and leading manufacturers often adopt an IDM business model. Among logic chip manufacturers, new entrants often adopt a Fabless model to reduce capital investment and concentrate more resources on research and development. Manufacturers in the optical chip industry mostly adopt the IDM model because optoelectronic devices follow unique processes, and the value enhancement of devices does not solely rely on size reduction but also depends on functional enhancements.

The IDM model is more conducive to independent control over all stages, enabling timely response to various market demands, flexible adjustment of production plans, and efficient troubleshooting, thereby improving chip performance and meeting downstream customer needs.